Air flow guide apparatus for microwave oven

A technology of air flow guidance and microwave ovens, which is applied in the field of microwave ovens, can solve the problems of complicated production and assembly, complex structure, and difficult production, and achieve the effects of simple structure, improved production efficiency, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

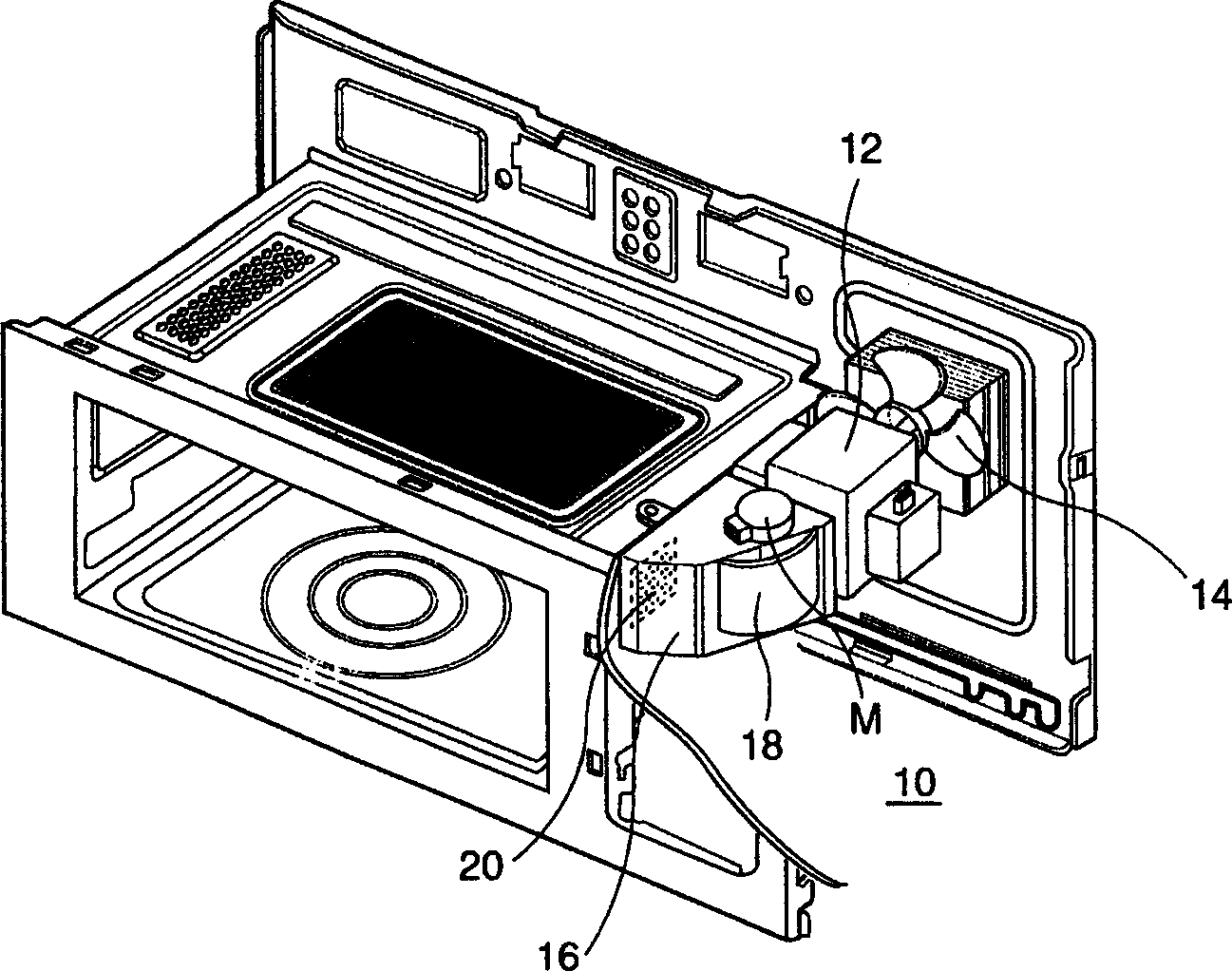

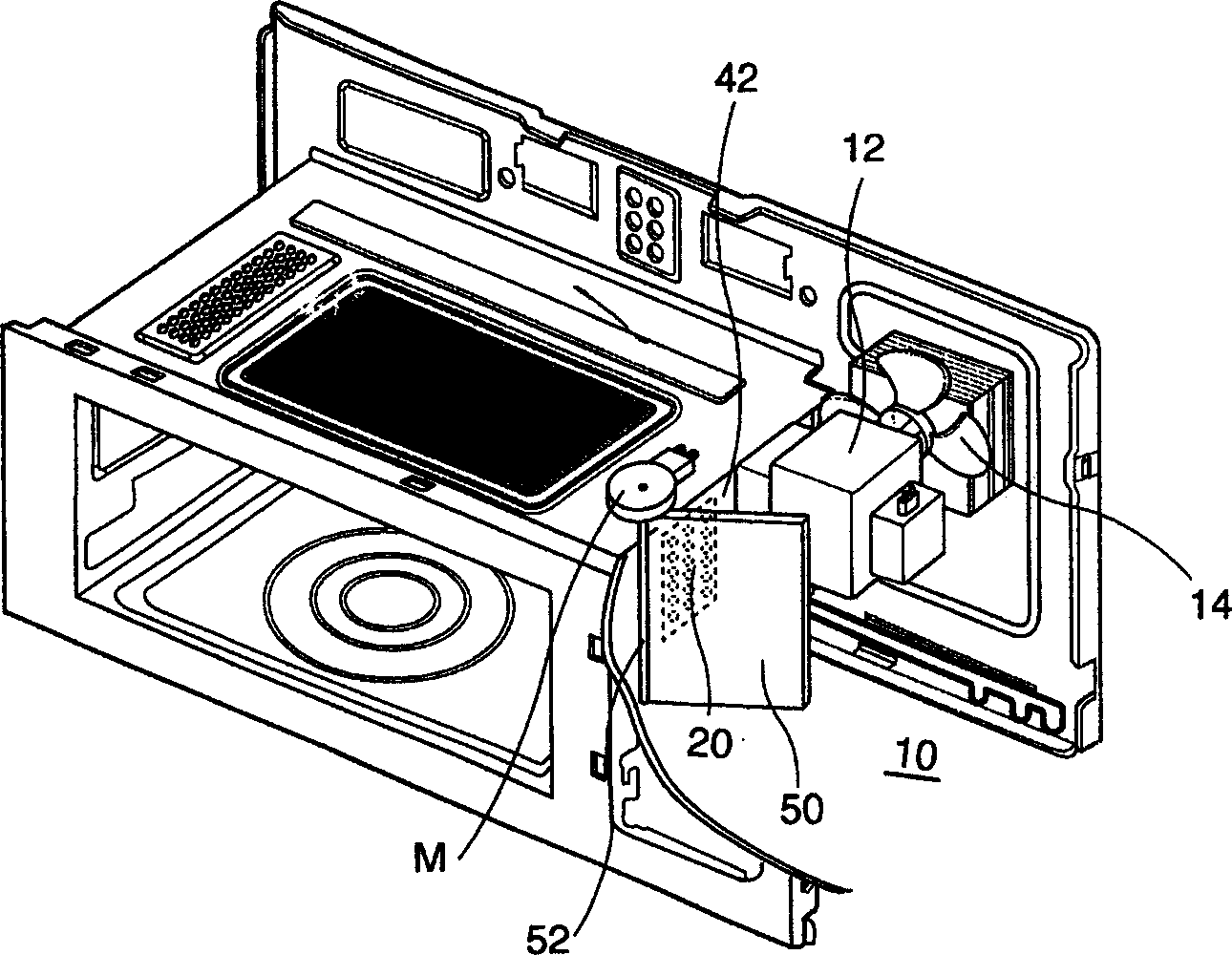

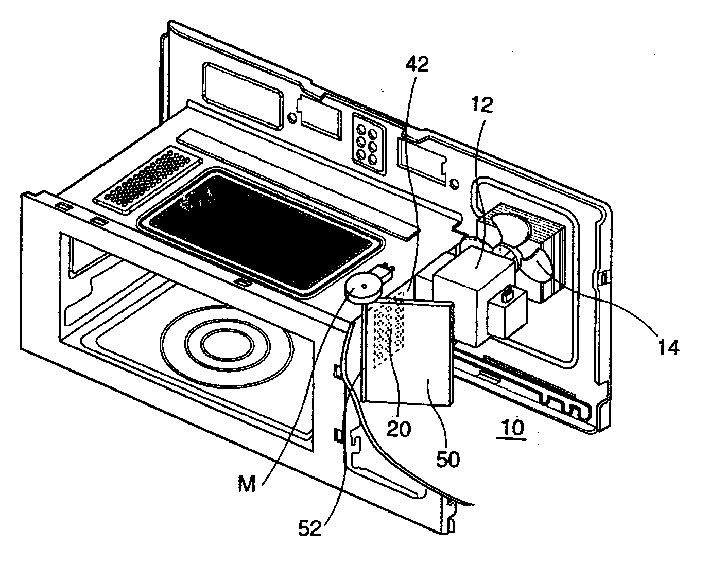

[0017] The air flow guide device for microwave ovens of the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments: figure 2 Here we can see the air flow guiding device according to the invention. As shown in the figure, the electric control room 10 is provided with a magnetron 12 for generating microwaves, and a blower fan 14 for generating airflow to dissipate heat from the magnetron.

[0018] The side wall 42 of the electric control room 10 is provided with a heating room inlet 20 connected with the heating room and formed by many ventilation holes. The air flow generated in the blower fan 14 will cool the magnetron 12 and transformer etc. while passing them.

[0019] The air flow cooling the aforementioned components will then flow into the heating chamber through the heating chamber inlet 20 located in the side wall 42 .

[0020] Next, let's take a look at the structure of opening and closing the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com