Elevator hoist and elevator device

A hoist and elevator technology, which is applied in the direction of hoisting devices, elevators in buildings, transportation and packaging, etc., and can solve problems such as time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be described below using the drawings.

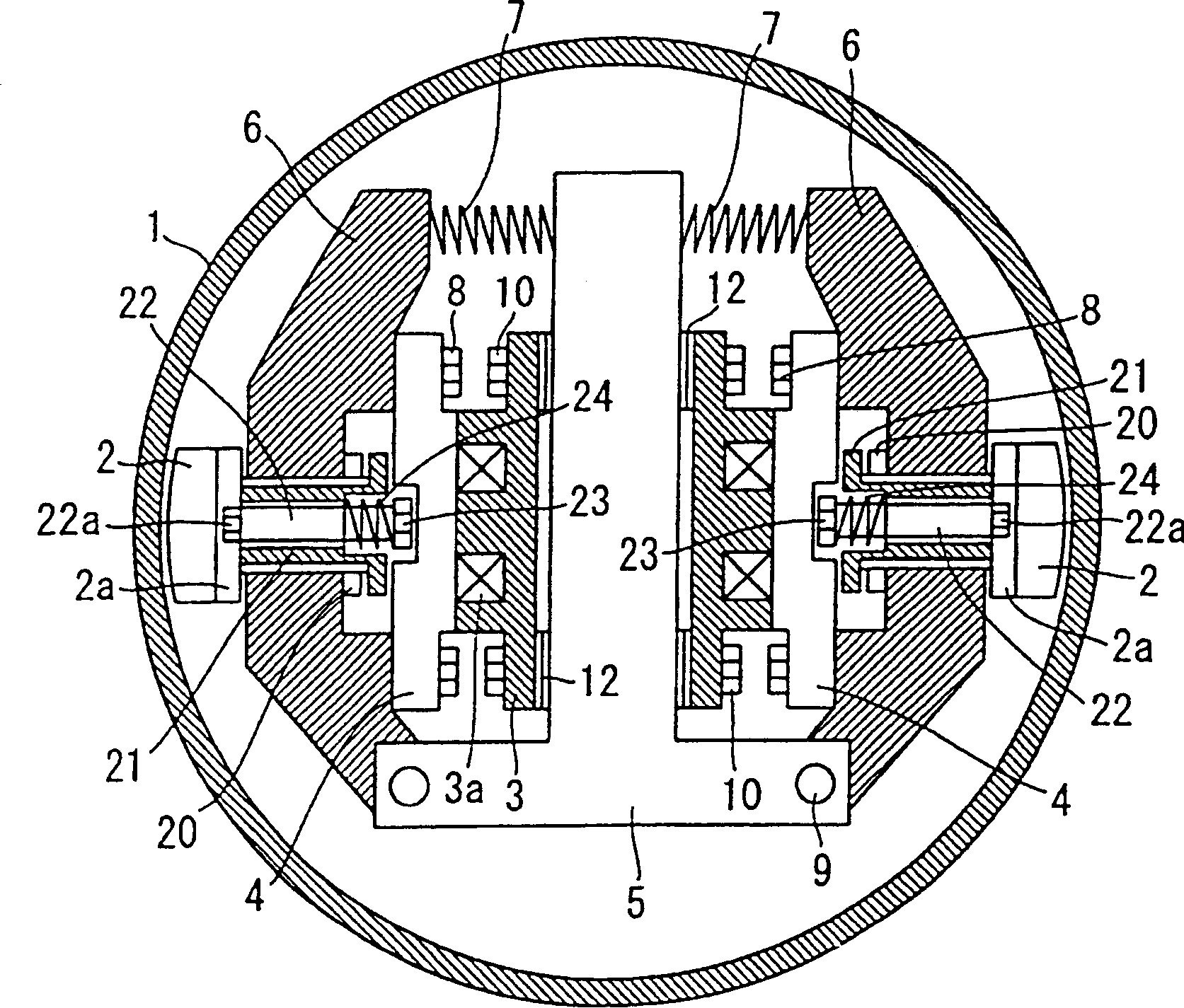

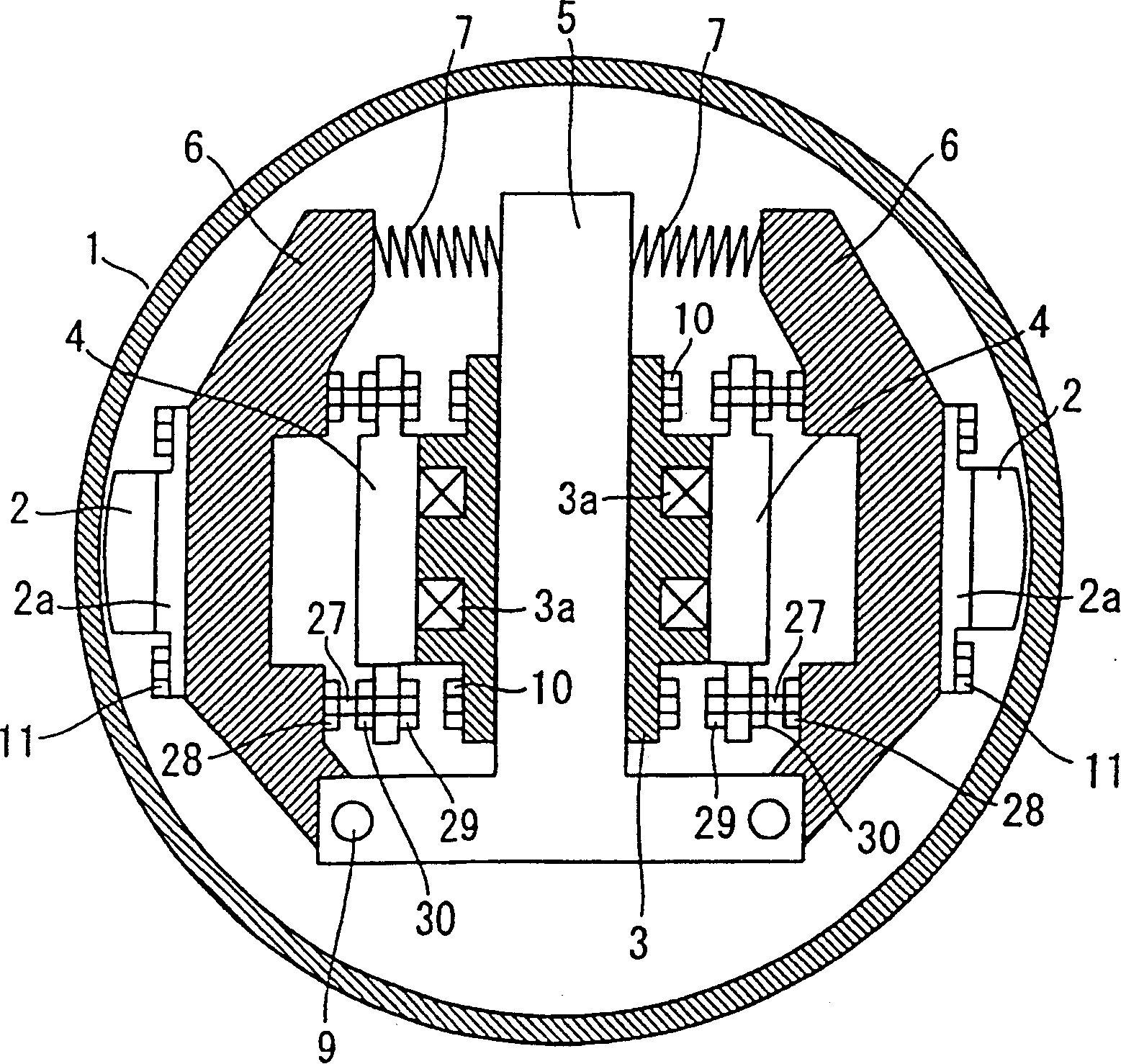

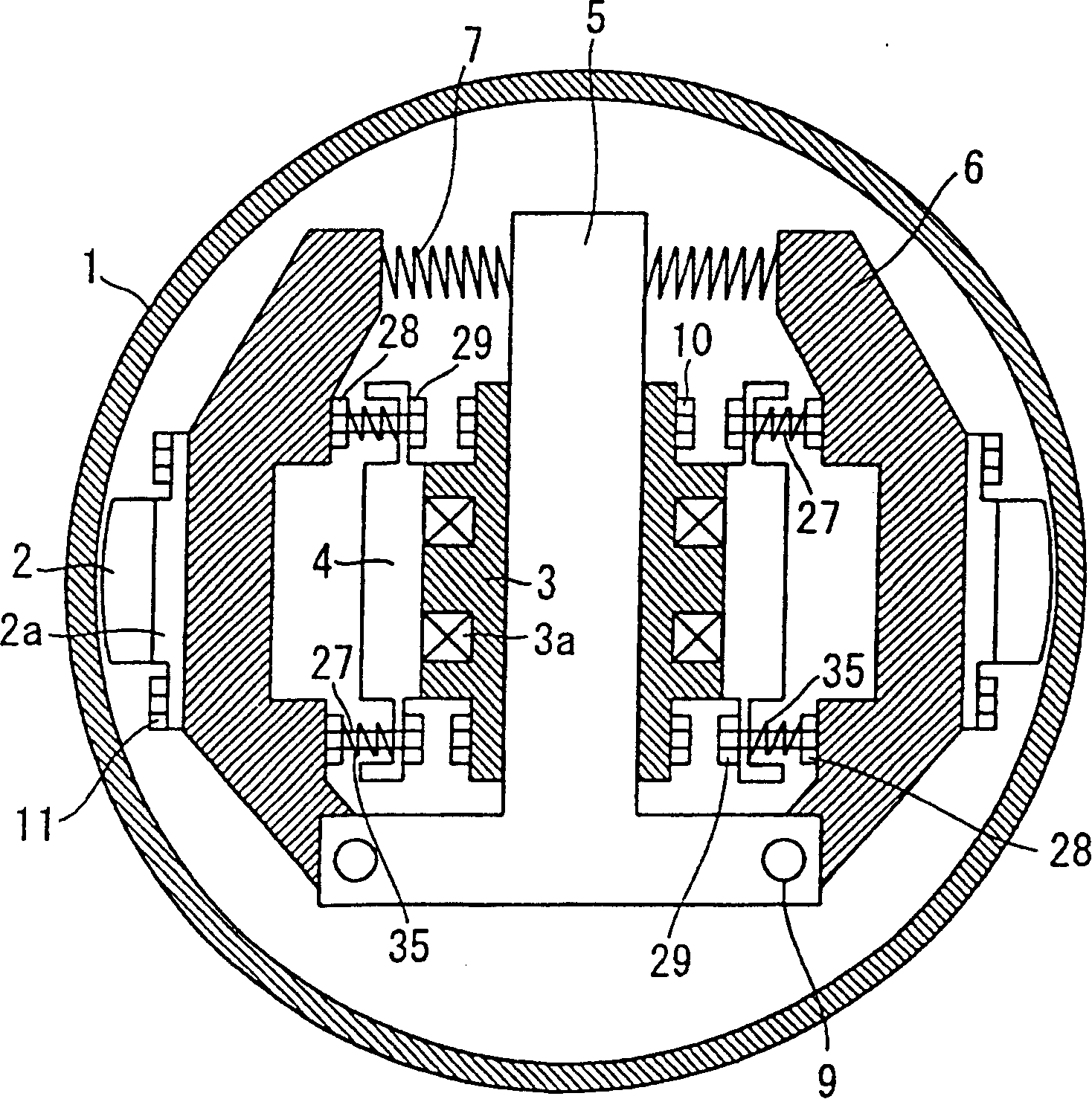

[0038] figure 1 It is a cross-sectional view showing the outline of an elevator hoist according to a first embodiment of the present invention.

[0039] As shown in the figure, a braking part is placed inside the brake drum 1 that is thrust and rotates around the main shaft not shown in the figure. The braking part is mainly composed of: a lining 2, a braking coil 3, an armature 4, and a coil The fixed part 5, the arm 6, the compression spring 7, and the washer 12 constitute.

[0040] In detail, the coil fixing part 5 is fixed at the central part of the brake drum 1 . The coil fixing part 5 is sandwiched, and the lining 2, the brake coil 3, the armature 4, the arm 6, the compression spring 7, the spacer 12 and other components are respectively arranged on both sides. Then, on both sides of the coil fixing part 5 , the brake coil 3 is screwed and connected by the bolt 10 by means of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com