Steel support frame

A technology for steel brackets and steel components, which is applied in the field of steel brackets, and can solve problems such as lengthening of drilling or screwing work, disengagement of screws, and weakening of structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

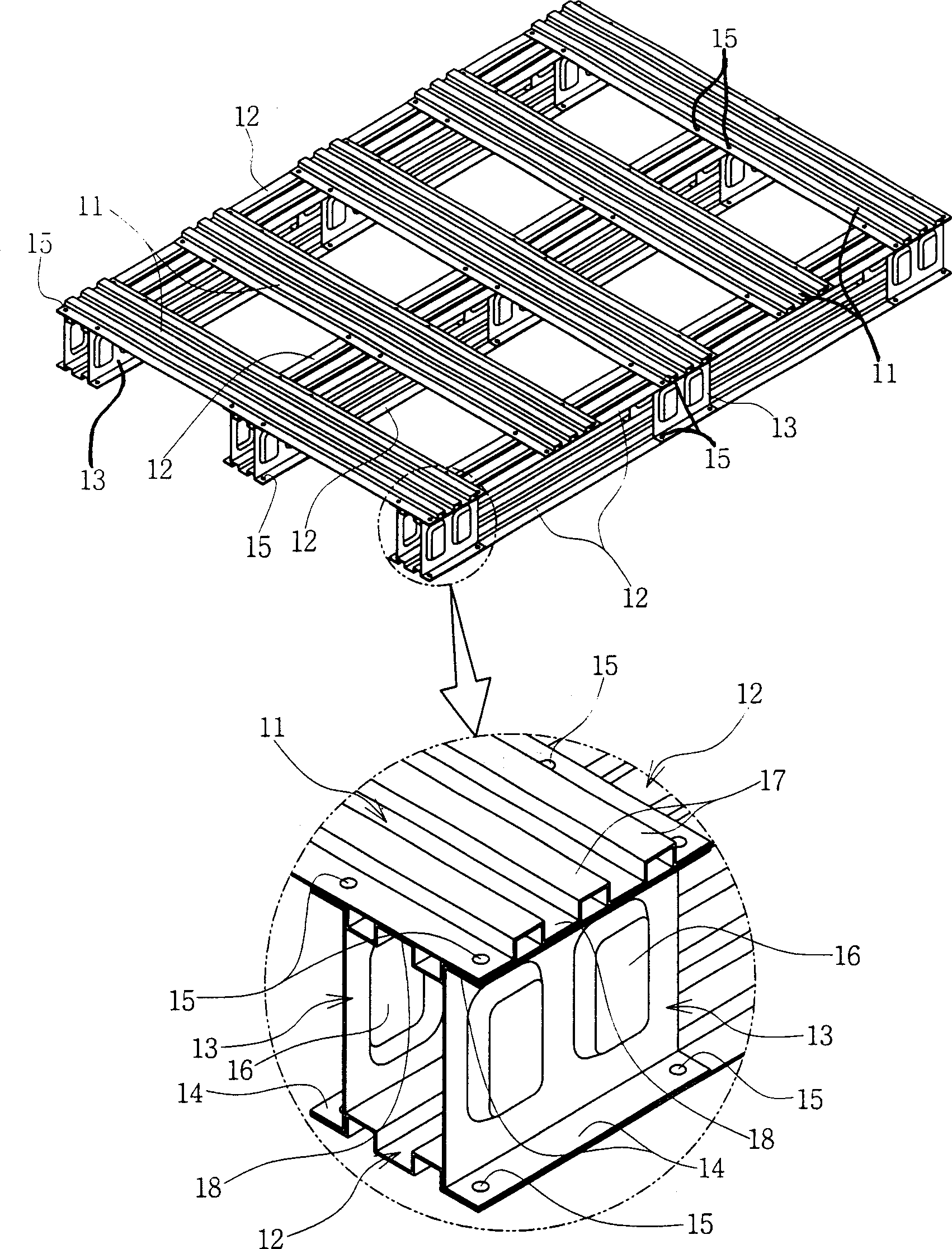

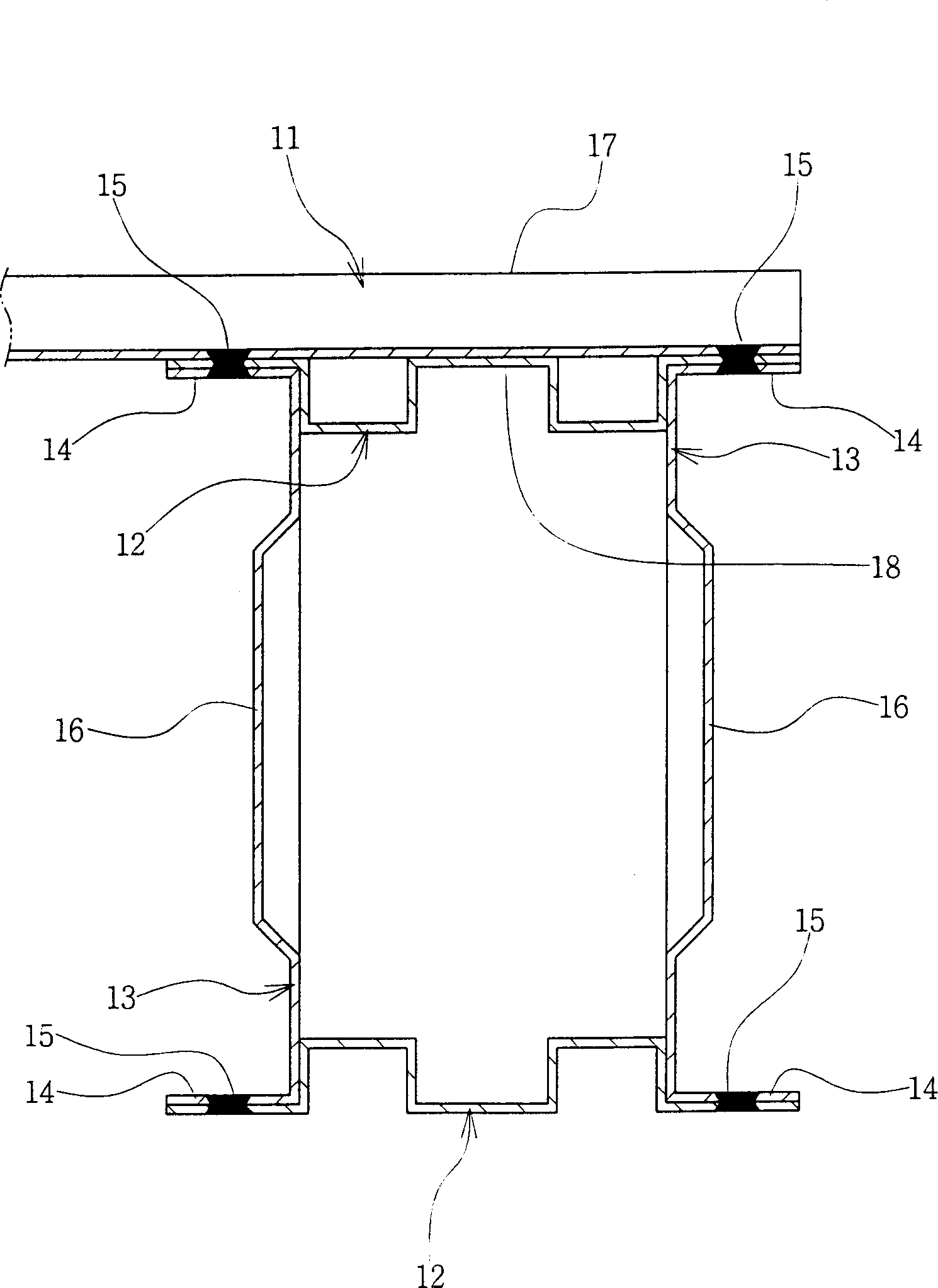

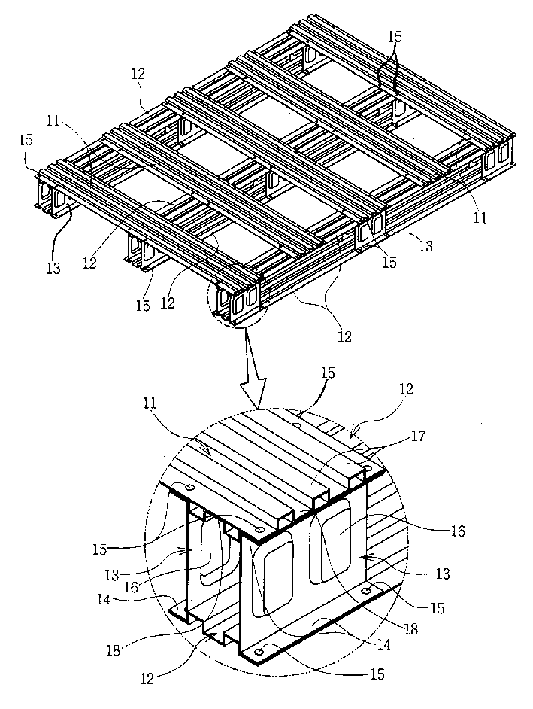

[0009] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings. Wherein, Fig. 1 is a structural view of a preferred embodiment of the present invention, figure 2 It is a partially enlarged cross-sectional view of this embodiment. As shown in these figures, the steel bracket 1 of the present invention includes an upper plate 2 and a plurality of strut members 13 fixed to the upper plate 2 by spot welding 15 .

[0010] The upper panel 2 is manufactured by combining a plurality of transverse steel members 11 and a plurality of longitudinal steel members 12 in a cross pattern. Here, the longitudinal and transverse members 11 , 12 are made of corrugated steel plates formed by folding the steel plates so as to alternately form recesses 18 and protrusions 17 . Also, the column member 13 is constituted by a pair of channel members 13a, 13b having a C-shaped cross section having flanges 14 at upper and lower ends. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com