Disk brake for cable

A technology of disc brakes and cables, applied in the direction of brake types, axial brakes, bicycle brakes, etc., can solve the problems of mechanical disc brake system with complex structure, high manufacturing cost, and required parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

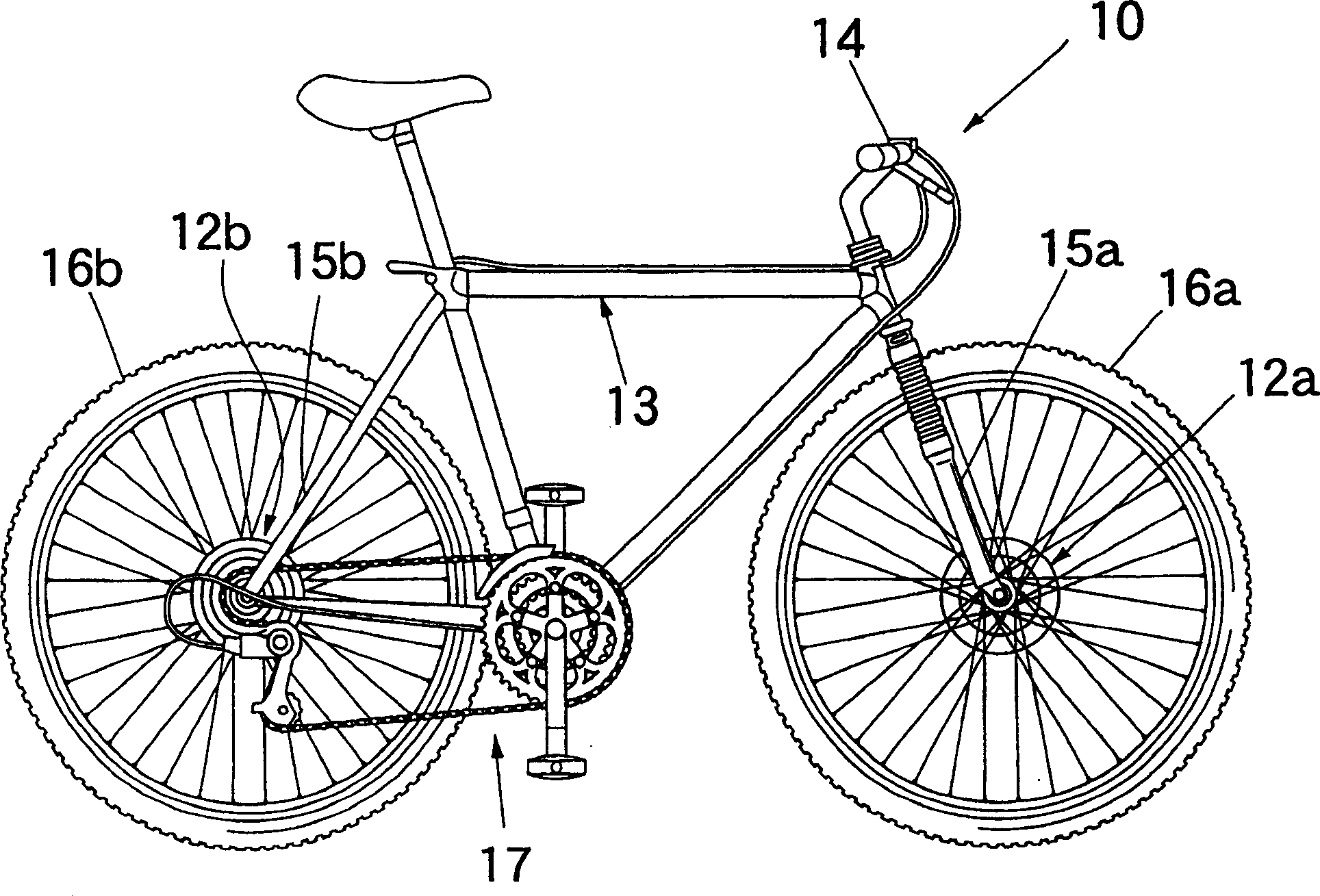

[0066] start reference Figure 1-3 , illustrating that the front and rear portions of the bicycle 10 are provided with a pair of cable disc brakes 12a and 12b connected thereto in accordance with one embodiment of the present invention. Bicycles such as bicycle 10 are well known in the art, so bicycle 10 and its various components will not be discussed or illustrated in detail here. It will be apparent to those of ordinary skill in the art to which the present invention pertains that the bicycle 10 may be any type of bicycle, such as a mountain bike, a hybrid bike or a road bike. The bicycle 10 is a conventional bicycle, which basically includes a bicycle frame 13 with a handlebar 14 , a front fork 15 a , a rear fork 15 b , a front wheel 16 a , a rear wheel 16 b and a drive chain 17 .

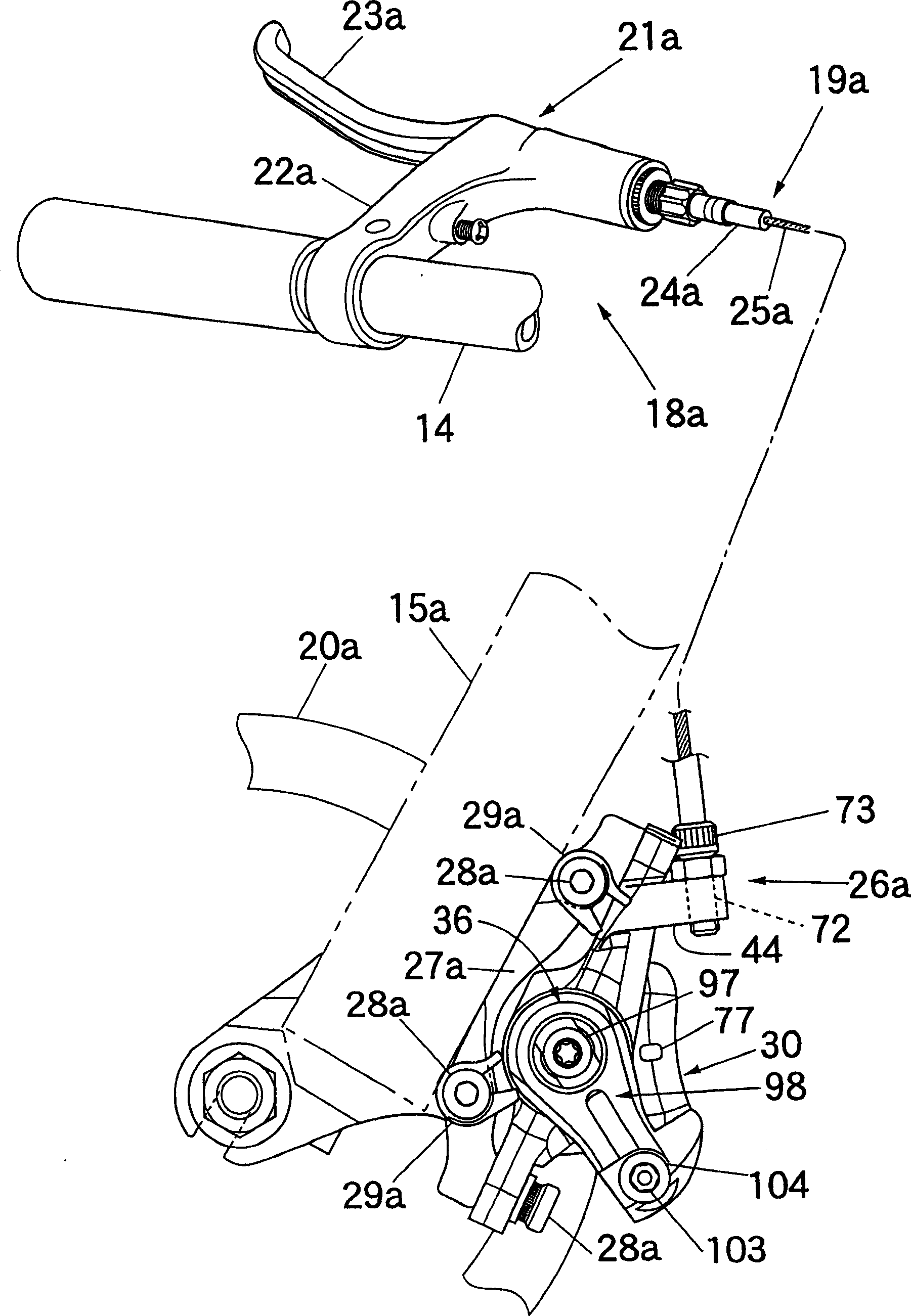

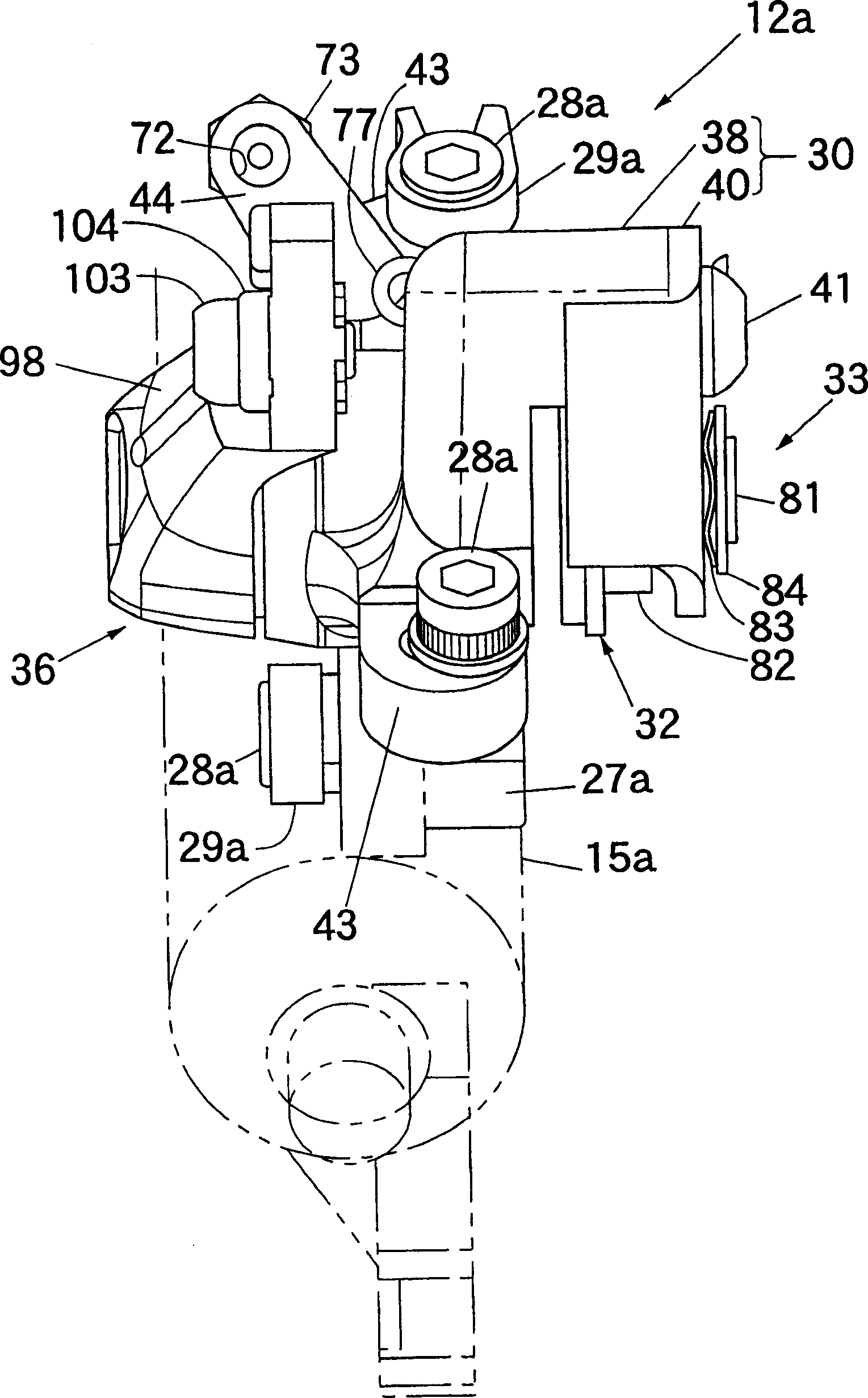

[0067] as in Figure 2-4 As seen in , the front and rear cable disc brakes 12a and 12b are identical to each other except for their connection to the bicycle 10 and their respective brake ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com