Paper processor and image forming device

A processing device and paper sheet technology, applied in the direction of thin material processing, stacking receiving device, electrical recording process using charge pattern, etc., can solve the problems of not being able to obtain a long life, difficult to save space, and folding corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. However, the dimensions, materials, shapes and relative arrangements of the components described in this embodiment should be appropriately changed according to the configuration and various conditions of the device using the invention, and the scope of the present invention is not limited to the following implementation example.

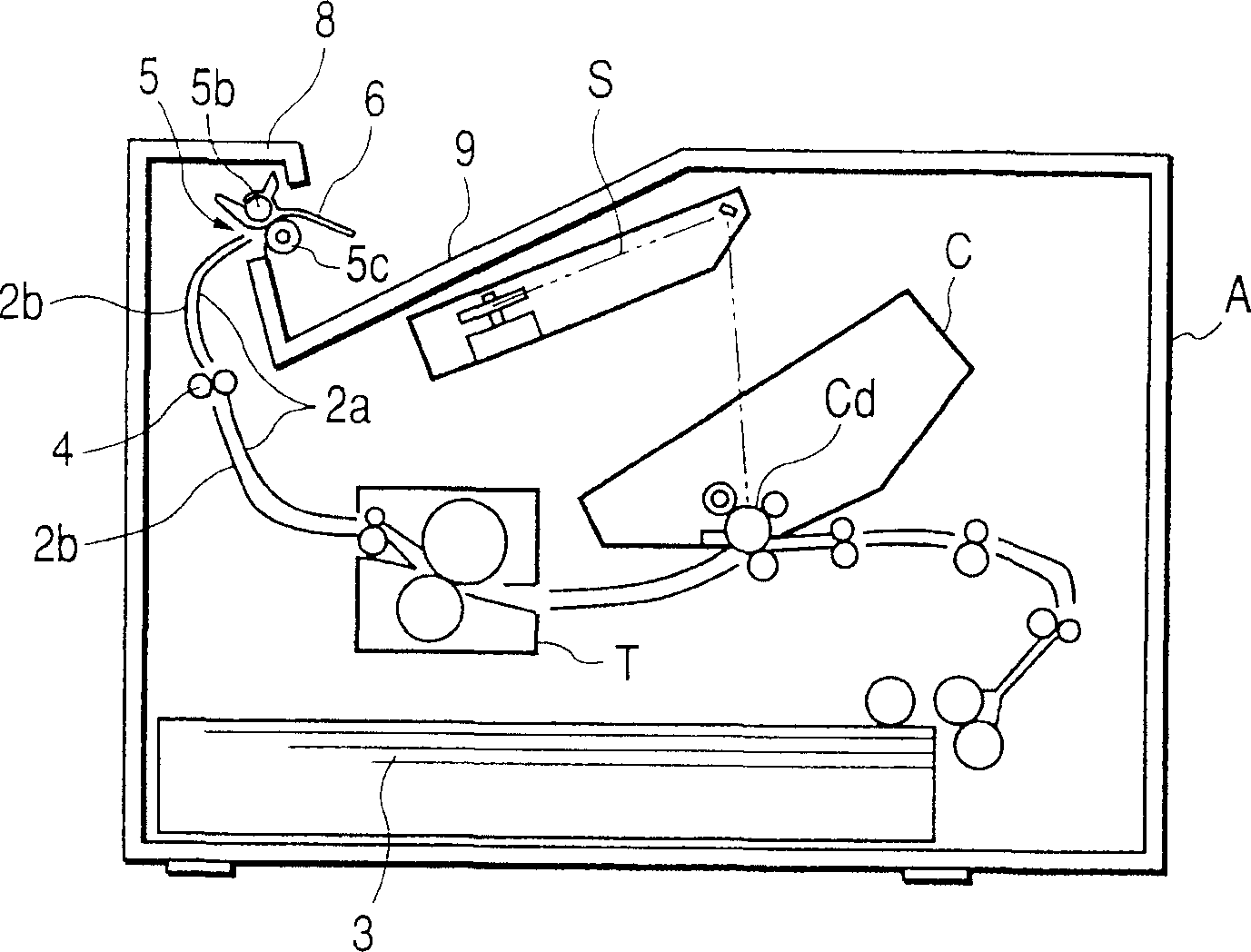

[0032] figure 1 It is a schematic cross-sectional view showing an image forming apparatus employing an electrophotographic method as the image forming apparatus of this embodiment.

[0033] Such as figure 1 As shown, in the image forming apparatus of this embodiment, a scanner S, a process cartridge C, an image fixing device T, and the like are provided in the apparatus body A. As shown in FIG. An electrophotographic drum Cd serving as an image carrier as an image forming apparatus is housed in a Process, cartridg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com