Paper materials feeding method and its apparatus and image forming apparatus

A paper material and feeding technology, applied in the direction of printing device, electric recording technology using charge pattern, equipment for electric recording technology using charge pattern, etc., can solve the problem of large feeding device, large diameter of paper feeding roller 154, difficult Device miniaturization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

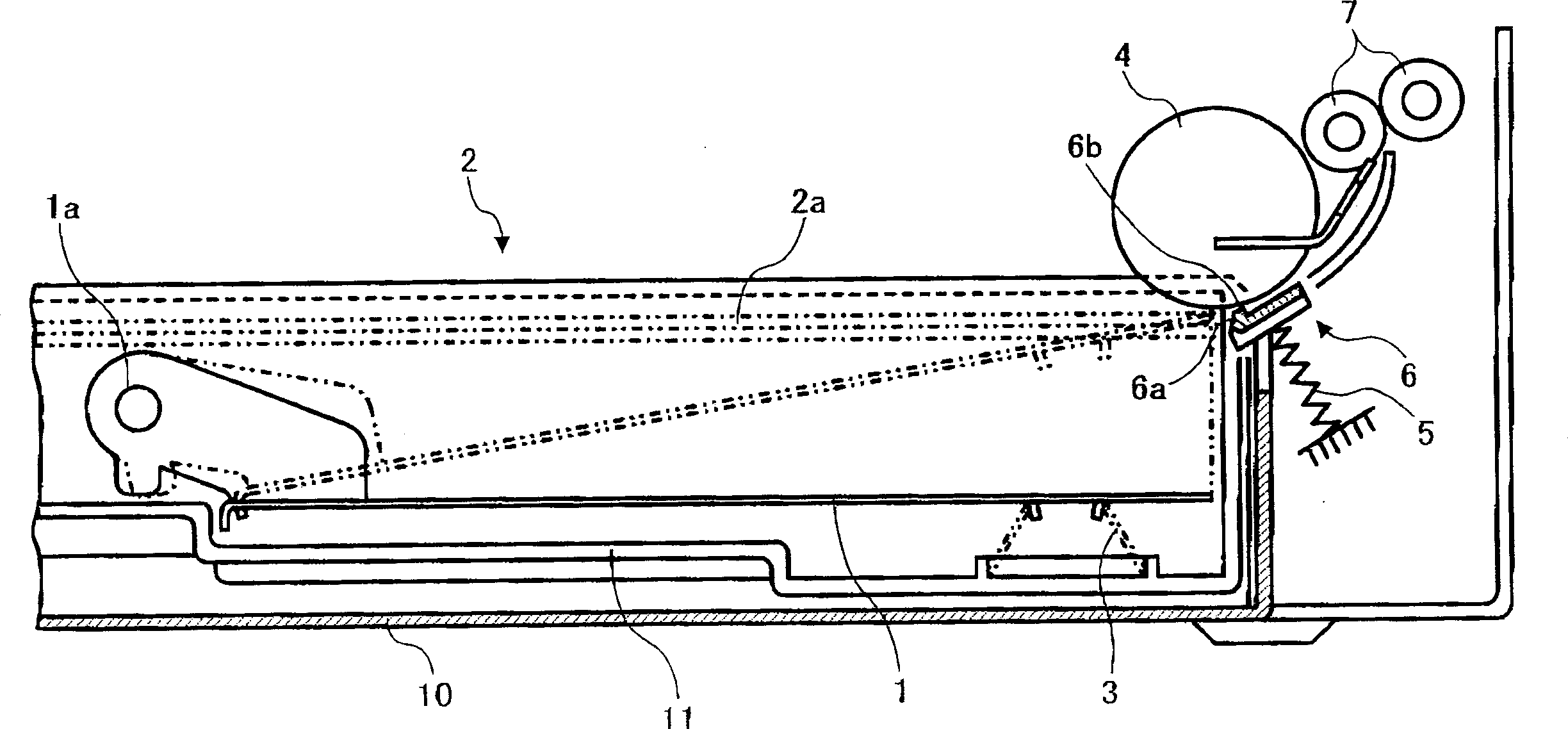

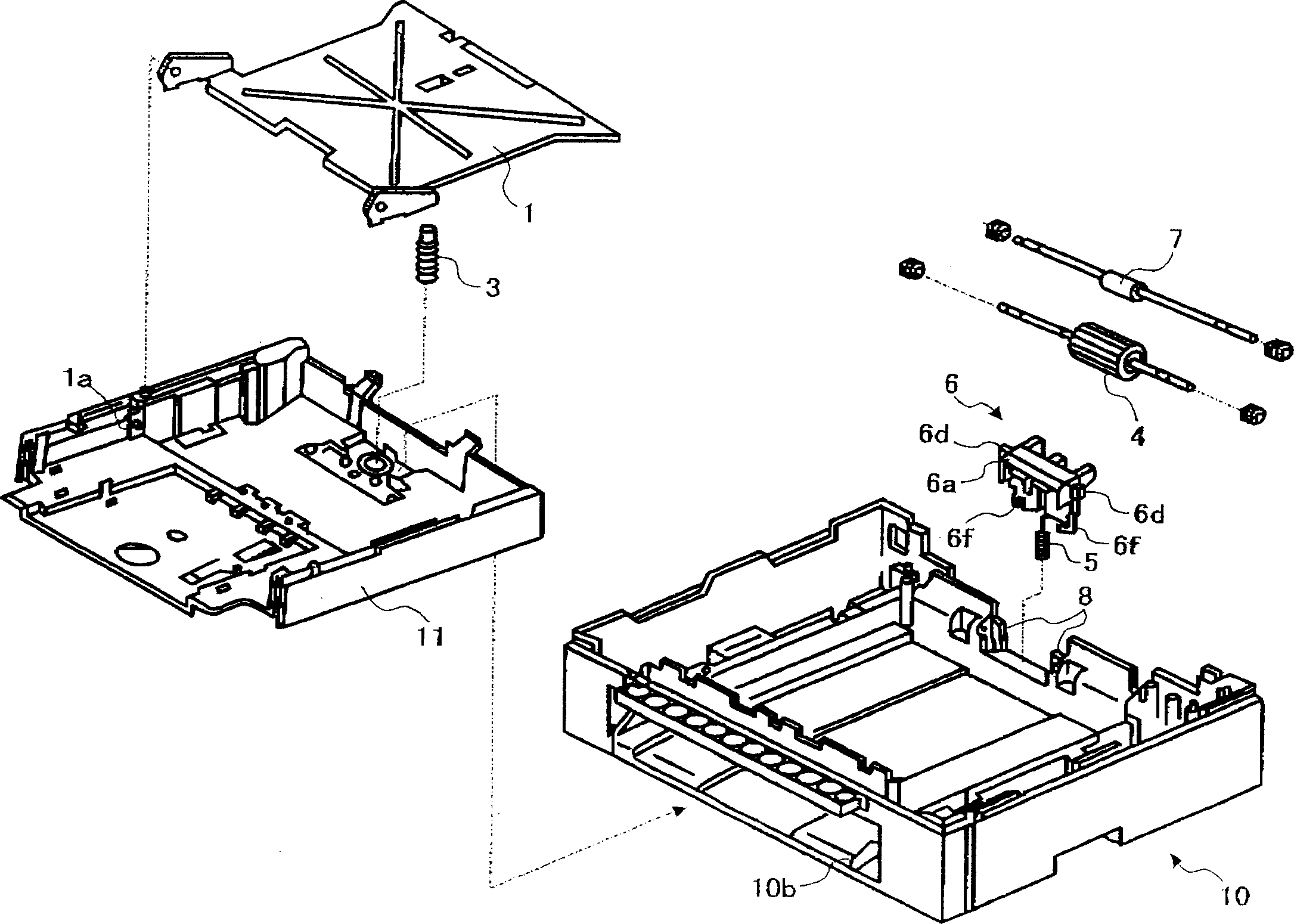

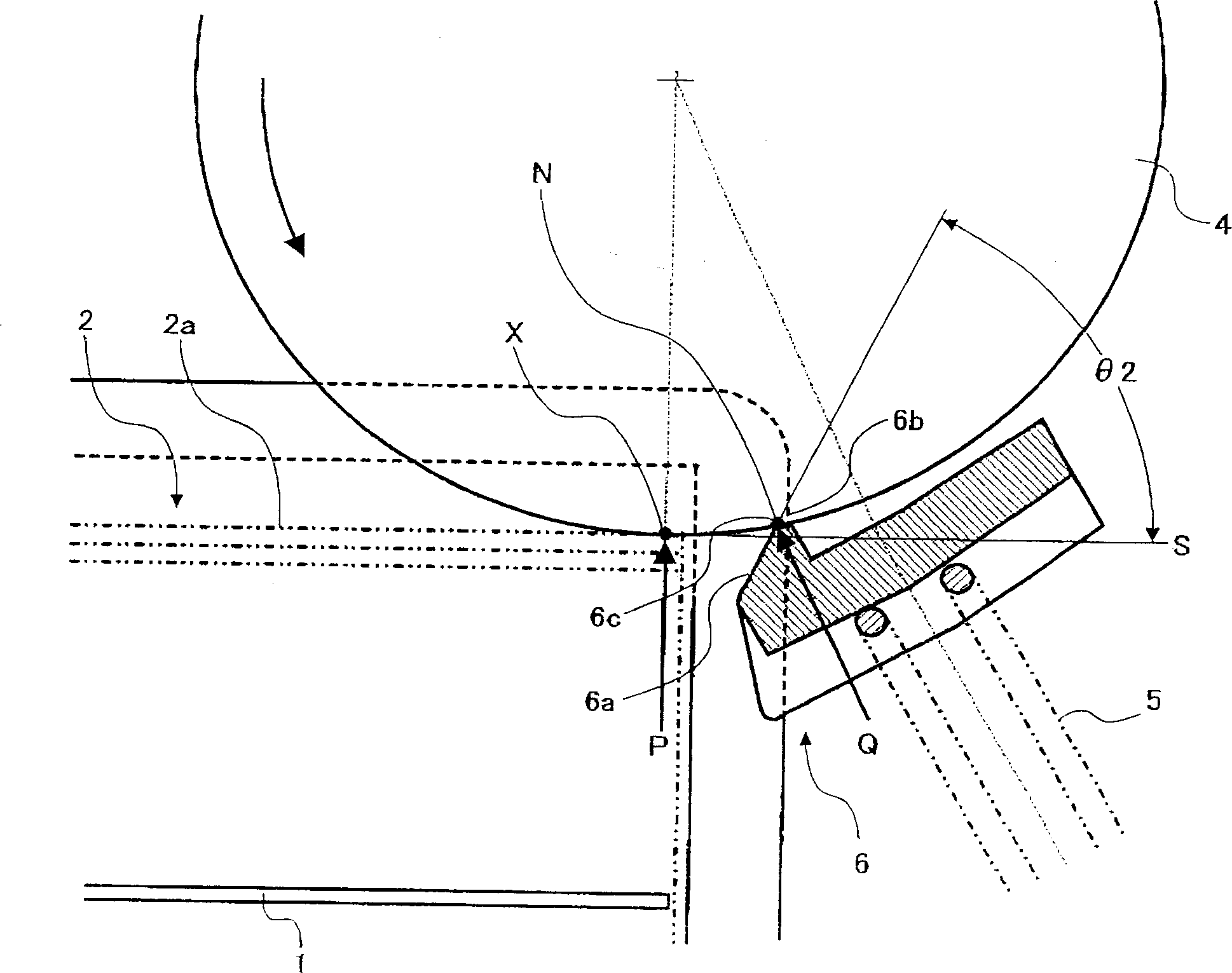

[0344] Hereinafter, a first embodiment of the present invention will be described in detail with reference to the drawings. figure 1 is a schematic longitudinal sectional view of the paper supply device according to the first embodiment of the present invention, figure 2 is an exploded oblique view showing its overall composition, image 3 is enlarged figure 1 Partial illustration.

[0345] first refer to figure 1 and figure 2 The overall configuration of the paper supply device of the present invention will be described. A case 11 is detachably attached to a shallow box-shaped apparatus body 10 provided with low-height walls around it through a side opening 10b. Inside the box 11, there is provided a bottom plate 1 as a paper material placing part, which can be placed such as figure 1 As shown in the plurality of sheets of paper 2, one end of the base plate 1 is freely supported by the support shaft 1a, and the compression spring 3 is connected with the box 11. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com