Diaphragm pump

A diaphragm and pump body technology, applied in the field of diaphragm pumps, can solve the problems of unfavorable manufacturing and assembly costs, complex structure, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

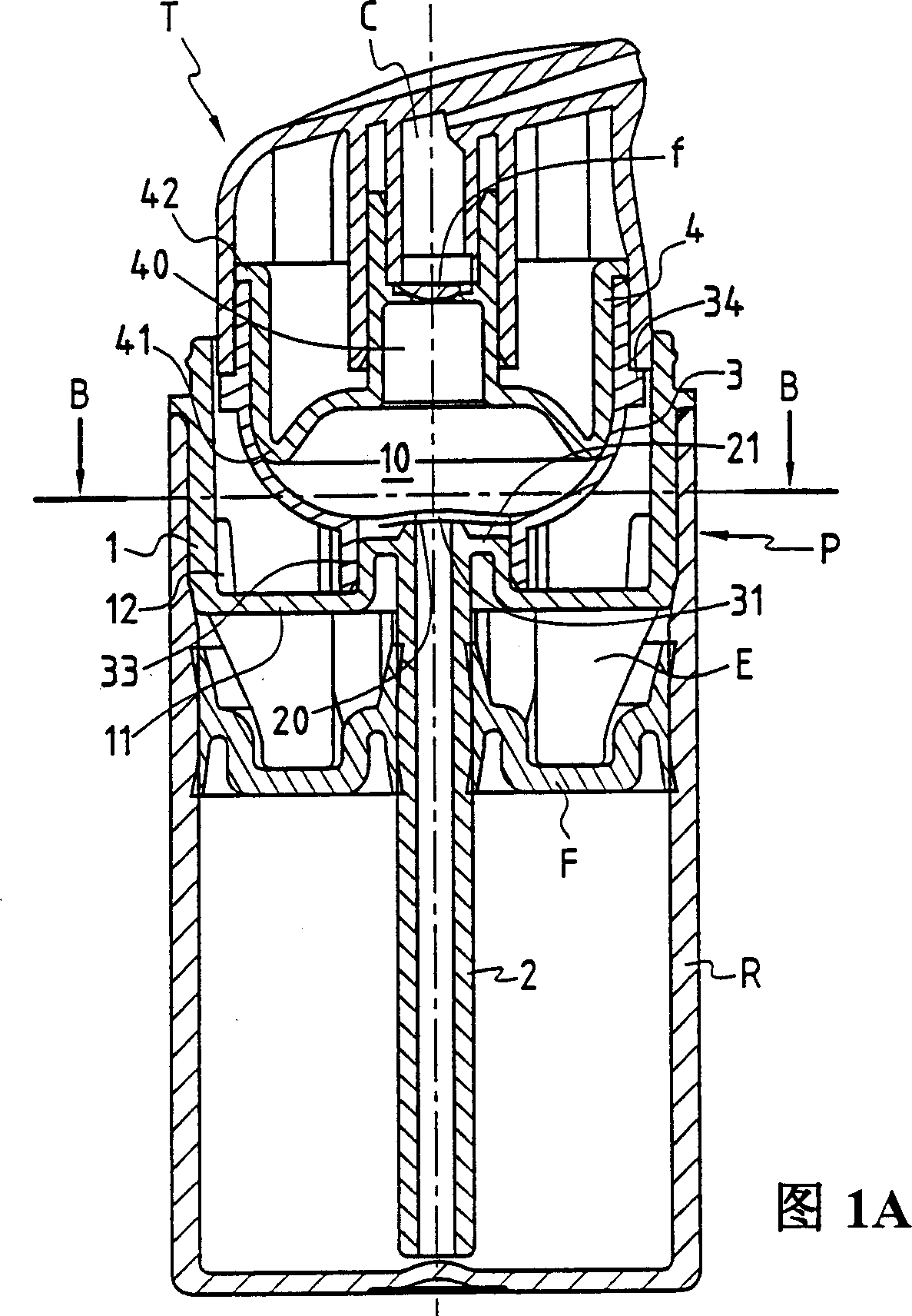

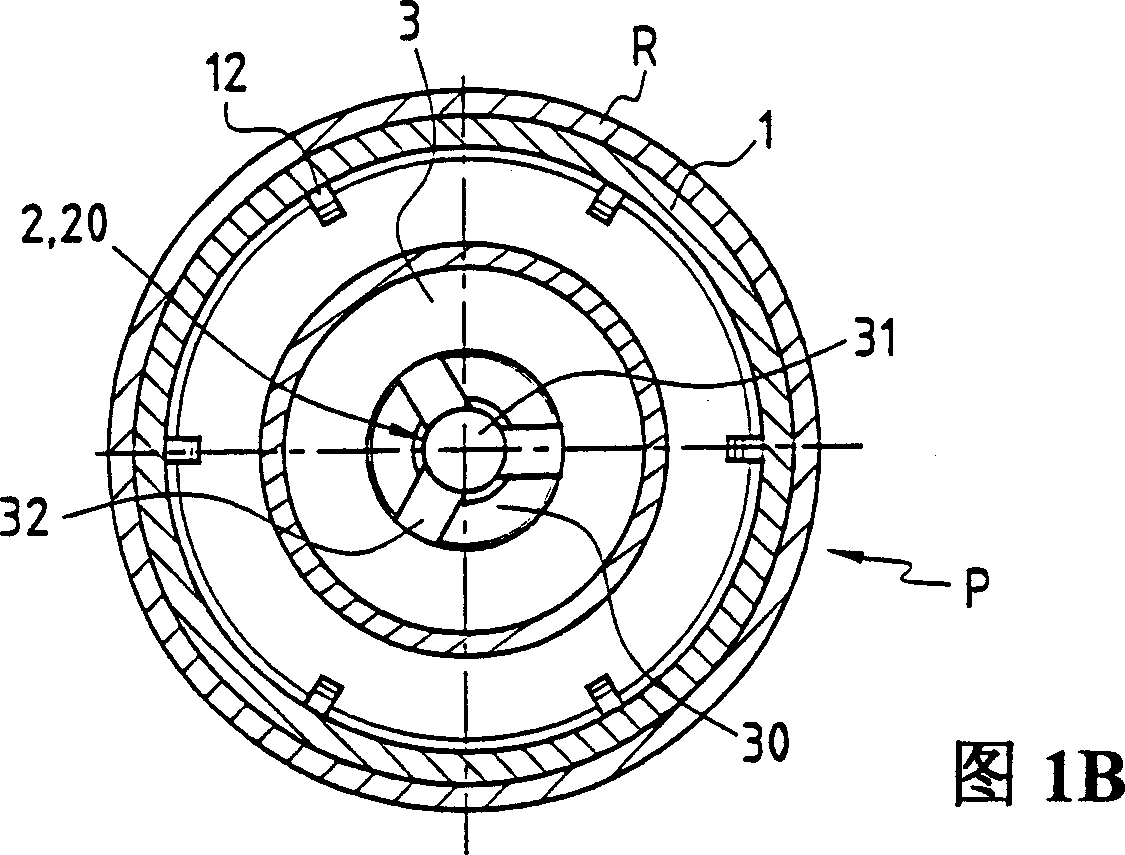

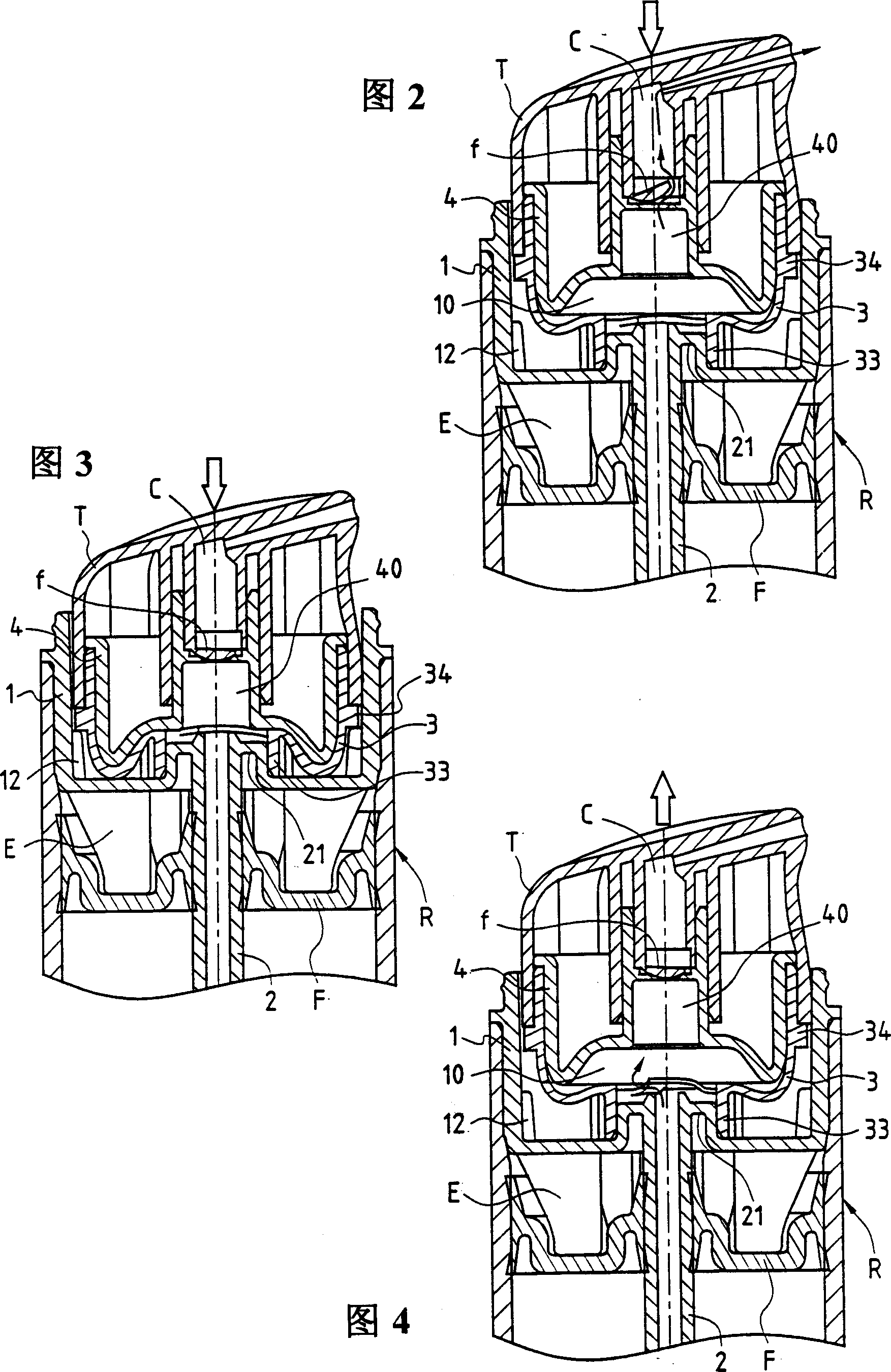

[0024] The pump P of the present invention shown in FIGS. 1A and 1B is used for dispensing a fluid or semi-fluid material in a container R .

[0025] The pump shown is of the "airless" type, that is, it has no air inlet and is therefore fitted with a movable partition F which both confines the contents of container R and scrapes the inner walls of the container.

[0026] During the continuous dispensing phase, the partition F in this example is adapted to move downwards from a high position where the container R is full, as shown in Figure 1A.

[0027] The pump P consists of a pump body 1, the pump body has a bottom, the bottom is connected with the immersion pipe 2 through the suction valve, the immersion pipe 2 is inserted into the material, the top of the pump body is connected with the top edge of the container R, when the container R is full, There is a pad E in the pump body 1 to prevent the movable partition F from moving upward.

[0028] The pump body 1 comprises a me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com