Object plane adjustment method of optical projection system based on defocus depth analysis and its device

A technology of optical projection and depth of defocus, applied in optics, projection devices, optical components, etc., can solve problems such as not being able to adapt to mass production, and achieve the effects of high adjustment accuracy, simple operation, and fast adjustment speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

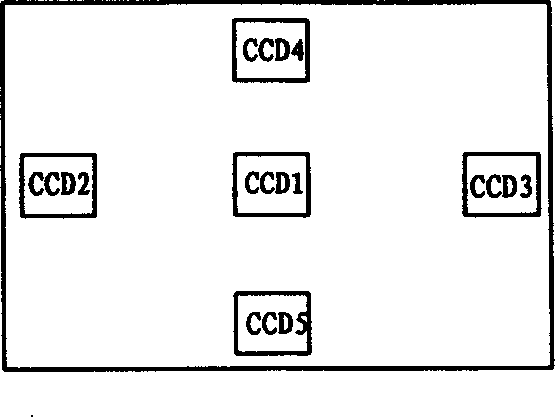

[0022] The object plane adjustment method of the optical projection system based on defocus depth analysis is characterized in that: multiple CCD image acquisition components are installed on the projection screen of the projection optical system to obtain images, and the object plane LCD of the optical projection system is obtained by analyzing the images. The defocus amount, horizontal tilt amount, vertical tilt amount, rotation amount and the relative position deviation of the three LCDs give the adjustment parameters.

[0023] Said CCD image acquisition assembly is: frosted glass is installed at the position of the projection screen, an imaging lens is installed thereafter, a CCD device is installed at the rear of the lens, the frosted glass and the CCD surface are respectively conjugated with respect to the lens, so that the image on the projection screen diffuses through the frosted glass. After being shot, the image is imaged on the surface of the CCD through the lens. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com