Preparation of powder of beta-TCP bioceramic possessing crystal grain structure of laminar clearage

A bio-ceramic and powder technology is applied in the field of preparation of β-TCP bio-ceramic powder with flaky cleavage grain structure to achieve the effect of being beneficial to degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

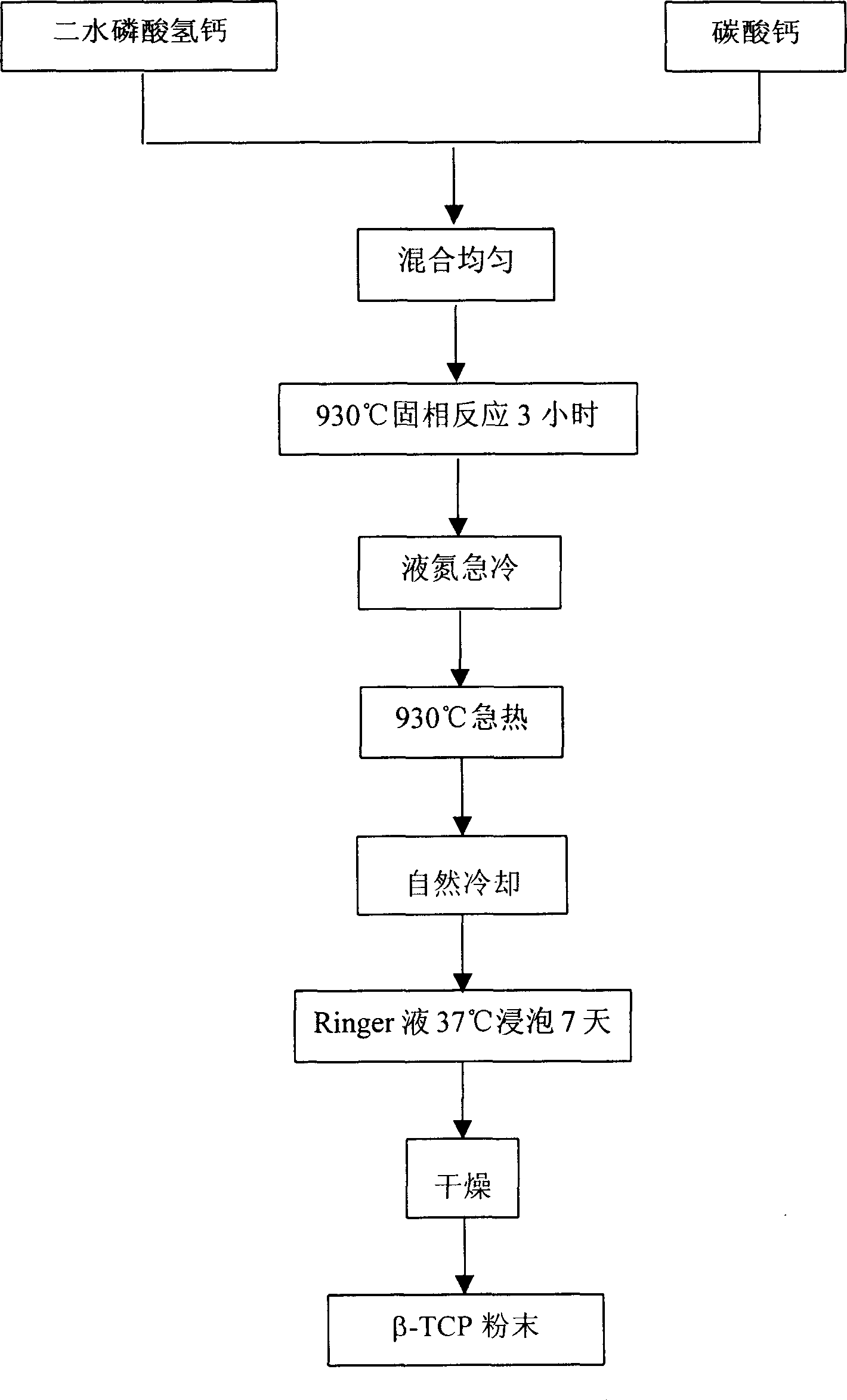

[0019] First, weigh the CaHPO 4 2H 2 O111.05g and CaCO 3 32.29g, after mixing, stir evenly with a mortar, put the raw materials into the electric furnace, raise the temperature to 930°C at a rate of about 6°C / min, and keep it warm for 3 hours. The following chemical reactions occurred:

[0020] (1)

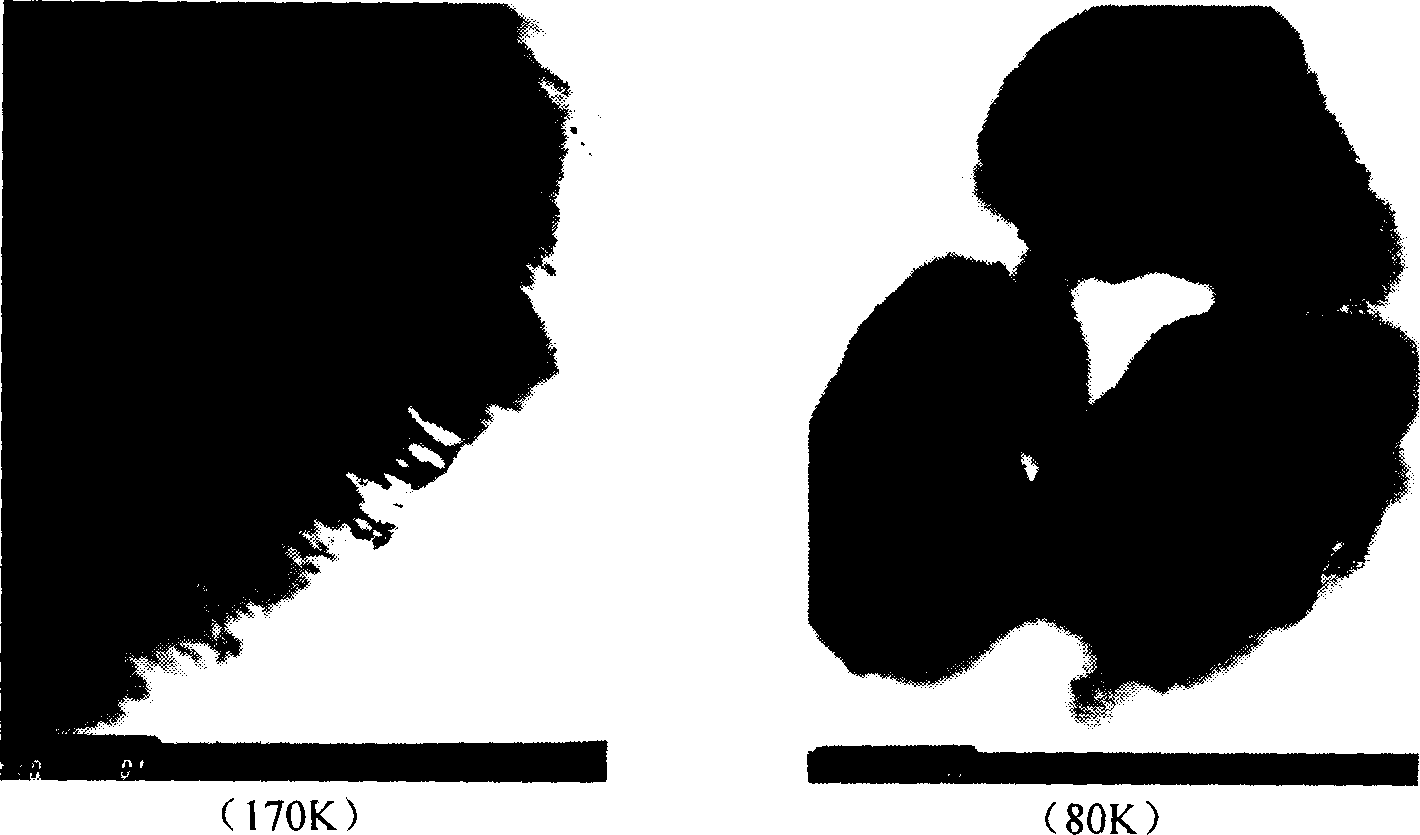

[0021] Then, take the powder out of the furnace, and quickly cool it with liquid nitrogen. After the temperature drops to the same temperature as the liquid nitrogen, put it into an electric furnace at 930°C for rapid heating, keep it for a certain period of time, and then cool it naturally with the furnace. Since the β-TCP material crystal belongs to the trigonal crystal system, its lattice parameters a0, c, and z are not equivalent. Under the extreme conditions of rapid cooling and rapid heating, the thermal shock caused by thermal expansion and contraction may be more severe in a certain direction , so that the bonding force between the crystal planes is des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com