Luminous diode illuminating light source device

A technology of light-emitting diodes and lighting sources, applied in lighting devices, parts of lighting devices, lighting and heating equipment, etc., can solve the problems of being unable to be effectively used for lighting, not easy to produce in large quantities, falling off, etc., to facilitate automatic assembly, Improved accuracy and high mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

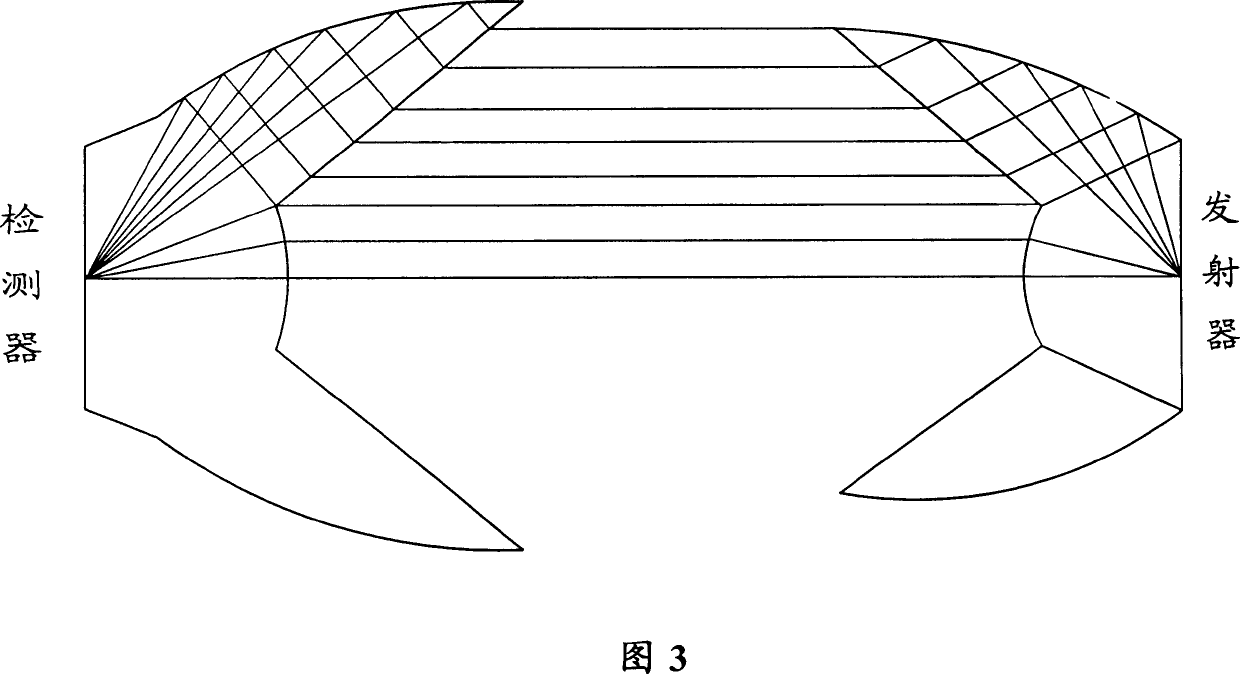

[0017] The present invention provides a light-emitting diode lighting source device, as shown in Figure 4-1, which is a schematic diagram of the light-emitting diode device of the present invention, and its structure mainly includes a substrate 1, a reflector platform 2, a concave basin reflector 3, a lens 4, Optical axis 5, LED grain 6, substrate optical axis positioning hole 7, convex lens 8, mirror optical axis positioning hole 9.

[0018] The substrate 1 can carry the light-emitting diode crystal grain 6 and the reflector platform 2. The shape of the reflector platform 2 can be square or hexagonal, and can be gathered together in a square or honeycomb arrangement; each reflection The mirror platform 2 can have a plurality of concave basin reflectors 3, the central bottom surface of the concave basin reflector 3 is hollow and the bottom surface of the hollow part is flatly attached to the substrate 1. Particle 6, and the concave part of the concave basin mirror 3 is a parab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com