Electronic ballast circuit with function of correcting power factor and load current amplitude factor

An electronic ballast, load current technology, applied in electric light sources, electrical components, lighting devices, etc., can solve problems such as increasing circuit complexity, and achieve the effect of good power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

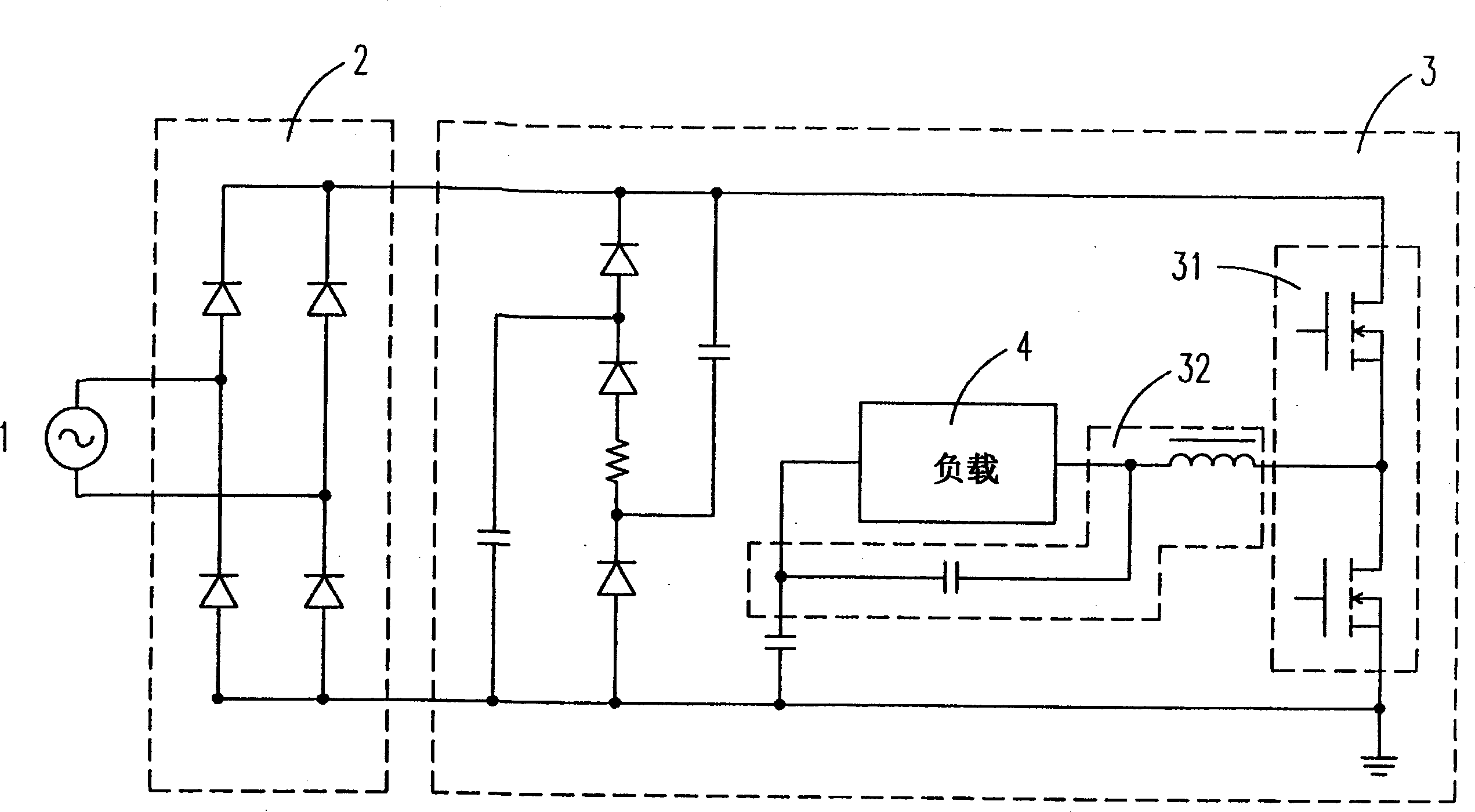

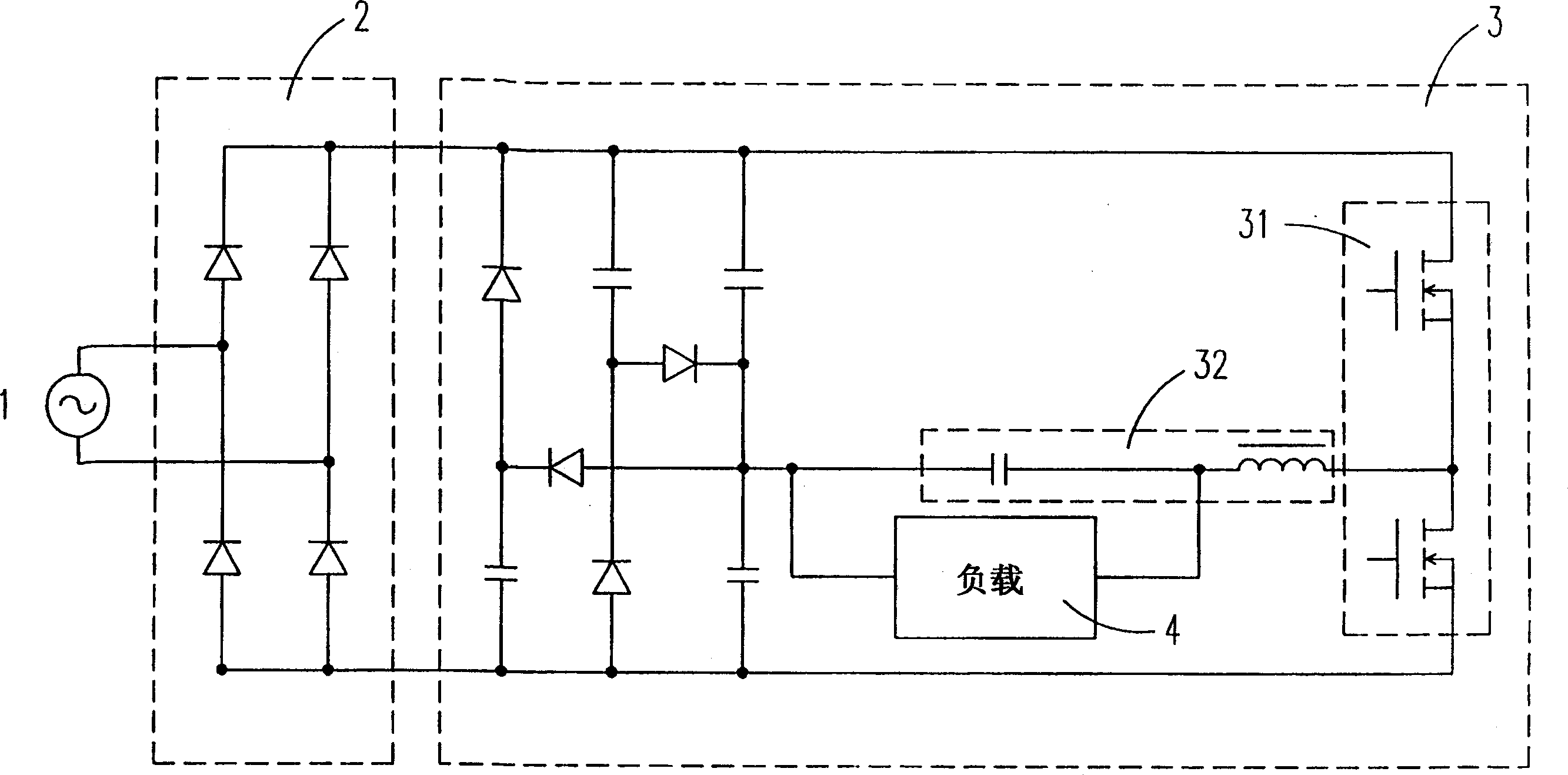

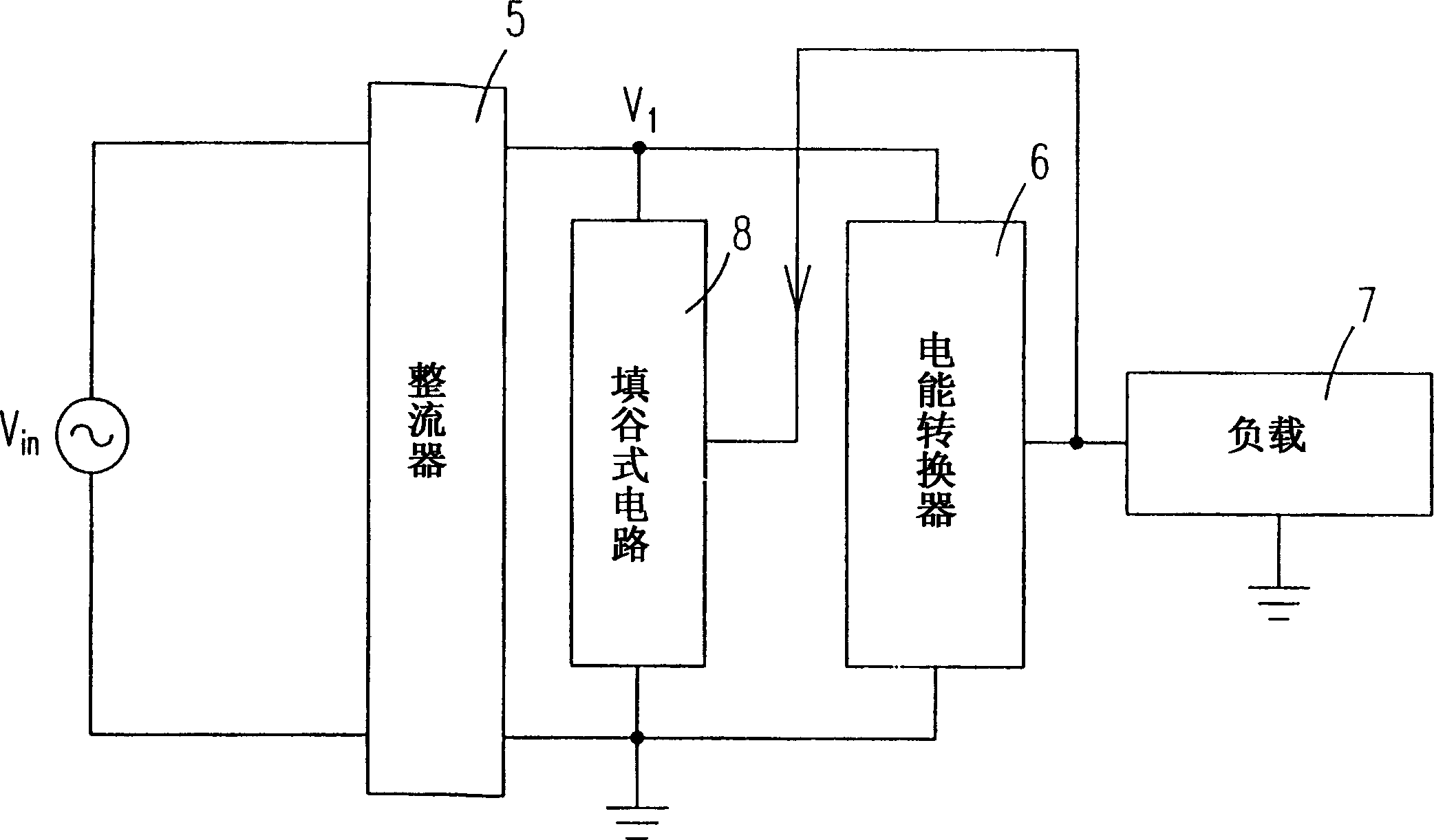

[0025] see figure 2 , is the circuit block diagram of the electronic ballast circuit with power factor and load current crest factor correction function according to the first preferred embodiment of the present invention. Such as figure 2 As shown, an electronic ballast circuit with power factor and load current crest factor correction function is electrically connected to an input power supply, which provides an input voltage V in , the electronic ballast circuit includes: a rectifier 5, a power converter 6 and a valley fill circuit (valley fill circuit) 8. The rectifier 5, which is electrically connected to the input voltage V in , the input voltage V in rectified to provide a first voltage V 1 . The power converter 6 is electrically connected to the rectifier 5, and the first voltage V 1 Do high-frequency switching output to provide electric energy for a load 7 . And, the valley-filling circuit 8 is electrically connected to an output end of the power converter 6 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com