Cigarette machine induced-draft pipe with adjustable draft velocity

An adjustable, cigarette machine technology, applied in the field of air suction pipes, can solve the problems of wind speed difference, affecting the quality of cigarettes, lack of adjustment of wind speed, etc., and achieves the effects of reasonable structure design, convenient installation and use, and improved cigarette quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

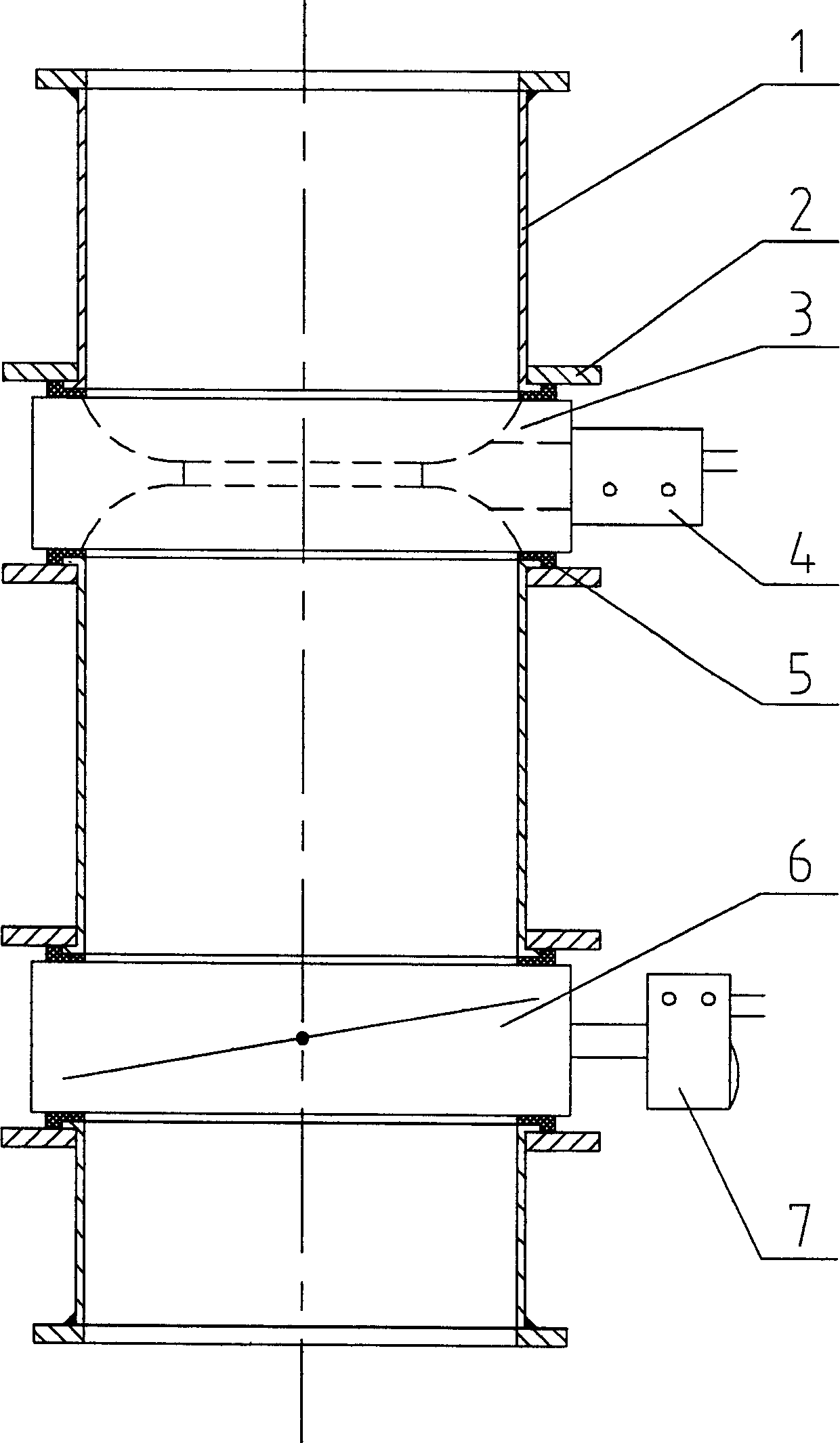

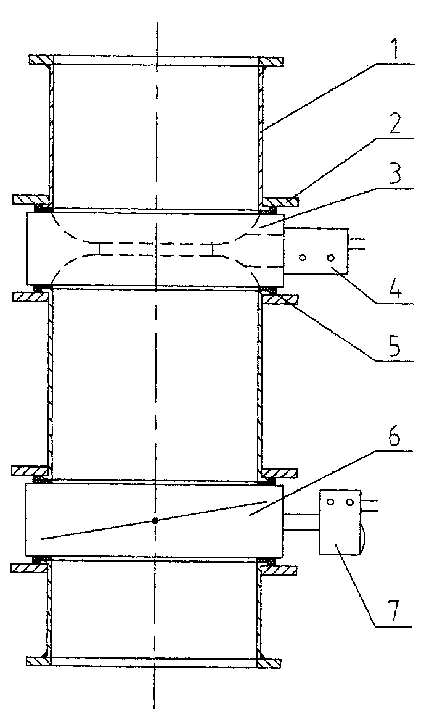

[0007] Referring to the accompanying drawings, the wind speed adjustable cigarette machine suction duct of the present invention includes an air duct 1 and a flange 2, and also includes a flow meter 3 and a damper 4, and the flow meter 3 and damper 4 pass through the flange 2 Connected in series in duct 1. 5 among the figure is the sealing ring on the flow meter or regulating valve. In order to facilitate the connection with the computer and realize automatic control, the flowmeter 3 is an orifice flowmeter, and the damper 6 is a 702Z-4I electric butterfly valve or a 702Z-3R pneumatic butterfly valve. The flanges at both ends of the suction pipe can be directly connected with the field air pipe. After installation, the signal output end of the differential pressure sensor 4 on the flow meter 3 is connected with the analog quantity input end of the computer, and the signal input end of the electric or pneumatic device on the adjustment damper 4 is connected with the analog sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com