Exhaust valve of sealed compressor

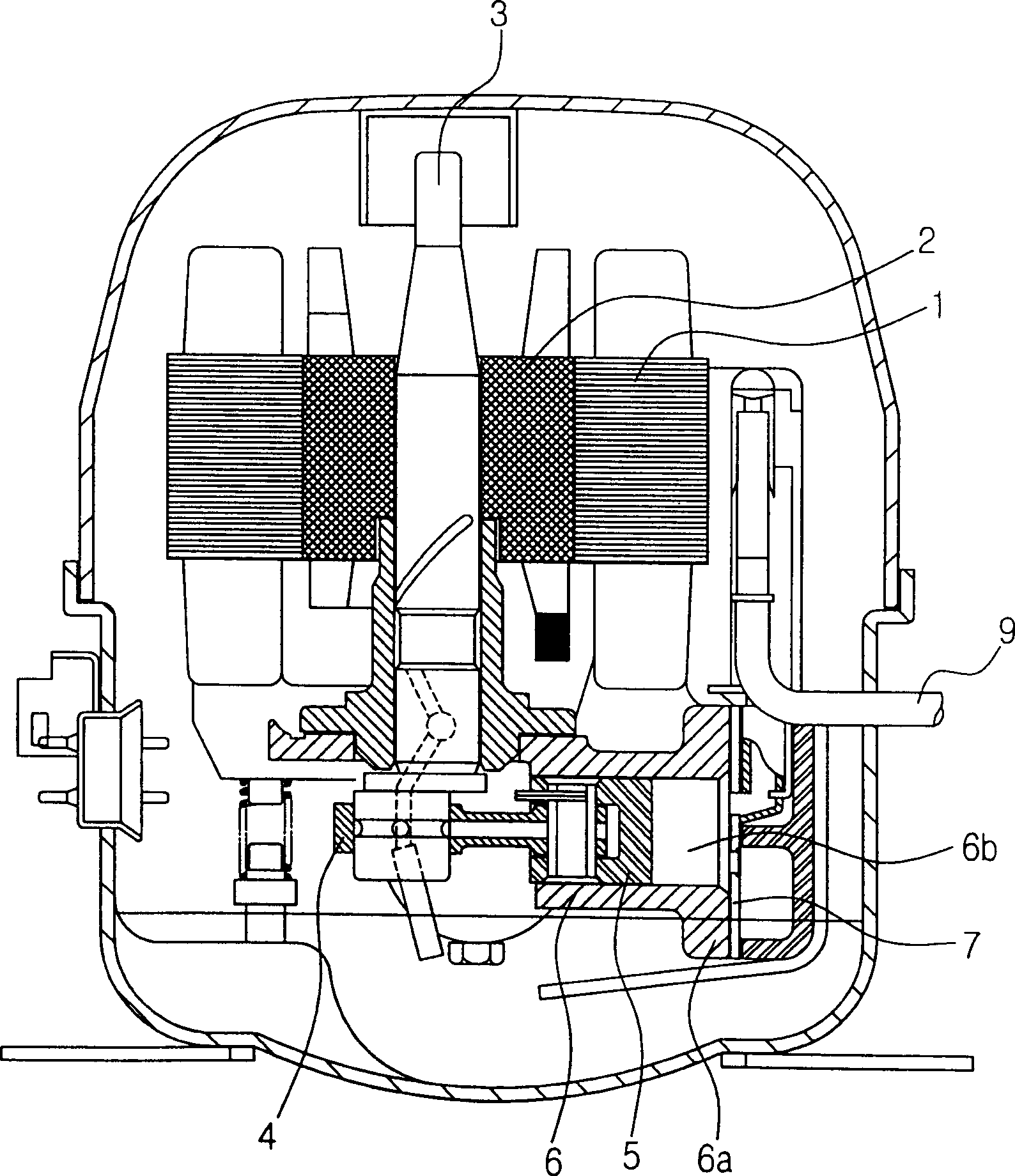

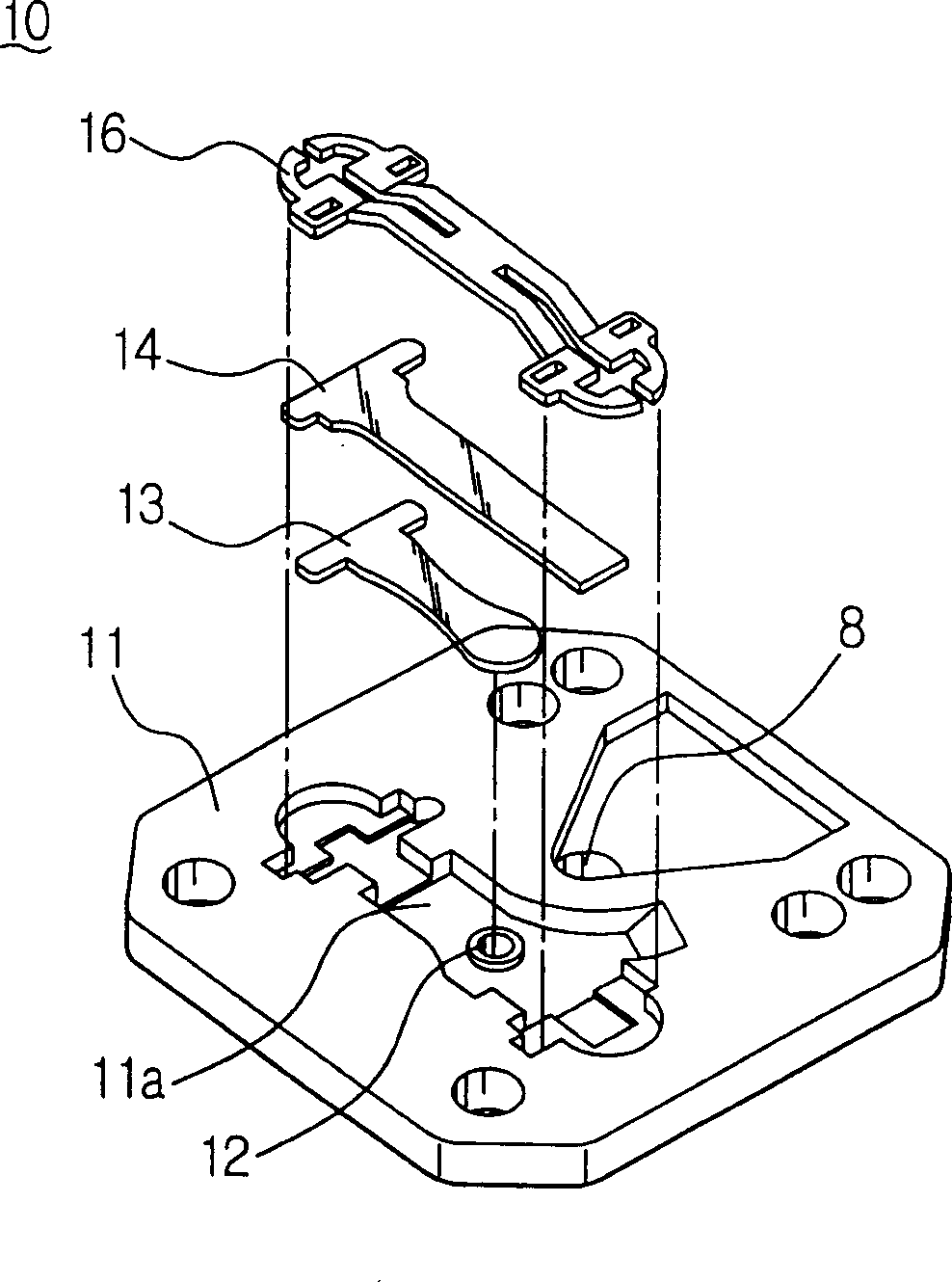

A technology of discharge valve and compressor, applied in mechanical equipment, machine/engine, liquid variable-capacity machinery, etc., can solve problems such as difficulty in manufacturing and assembling, increase in compressor noise, complex shape and structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

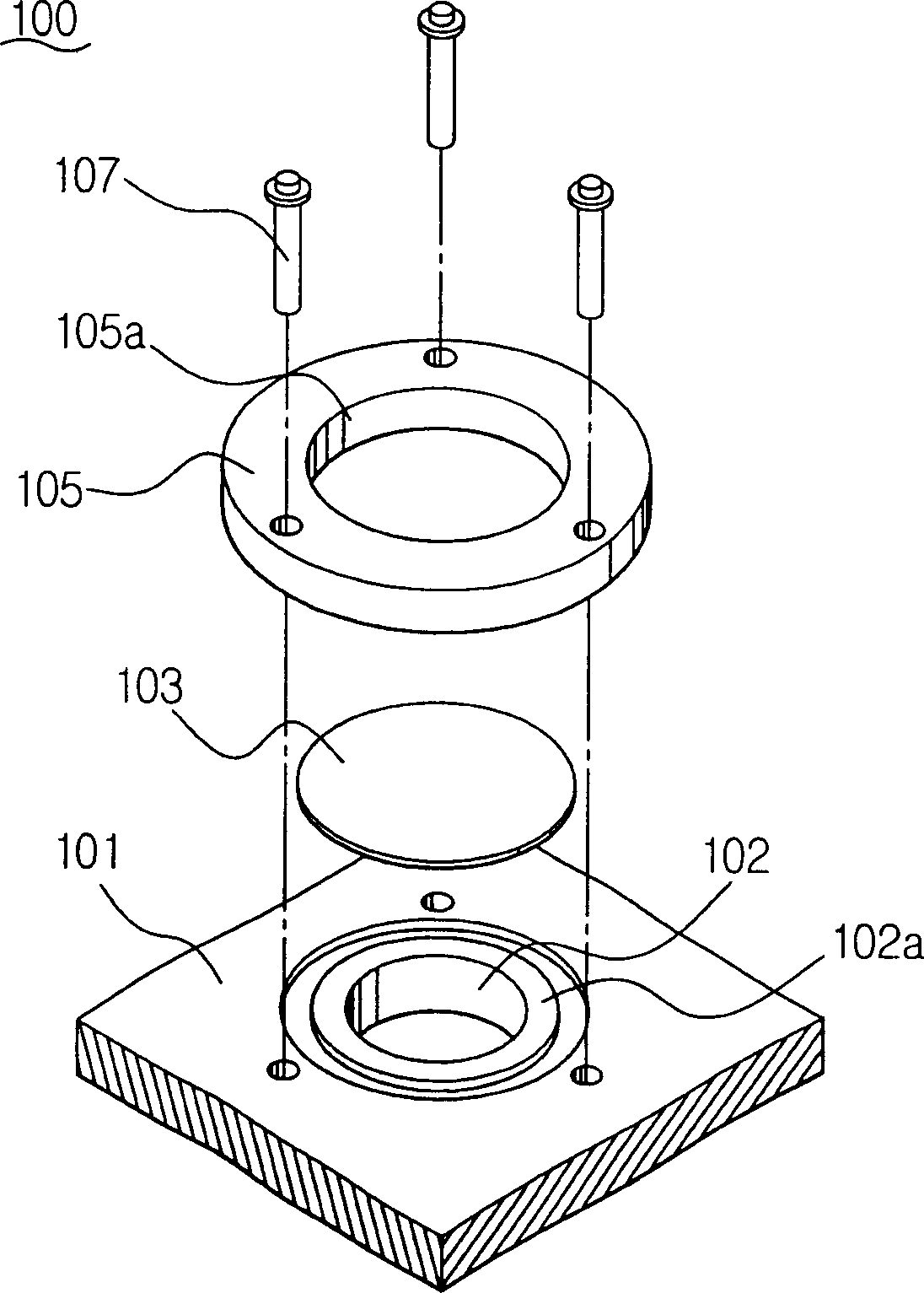

[0033] Hereinafter, the preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0034] refer to Figure 3-5B , The hermetic compressor 100 according to the first embodiment of the present invention includes a valve plate 101 , a plate valve 103 , a stopper 105 and some guide pins 107 .

[0035] A valve plate 101 disposed on the cylinder head has a discharge hole 102 for discharging refrigerant and a suction hole (not shown) for sucking refrigerant into the compression chamber. As shown, the seat 102A is positioned on top of the discharge hole 102 so that the plate valve 103 can effectively close the discharge hole 102 .

[0036] The plate valve 103 for closing the discharge hole 102 is located on the top of the discharge hole 102, and its weight helps to compress the refrigerant when the discharge stroke closes the discharge hole, and when the pressure in the cylinder exceeds the weight of the plate valve, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com