Hydrophilic nano montmorillonoid and its prepn

A nano-montmorillonite and hydrophilic technology, applied in the field of nano-materials, can solve problems such as nano-montmorillonite and nano-montmorillonite that have not been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

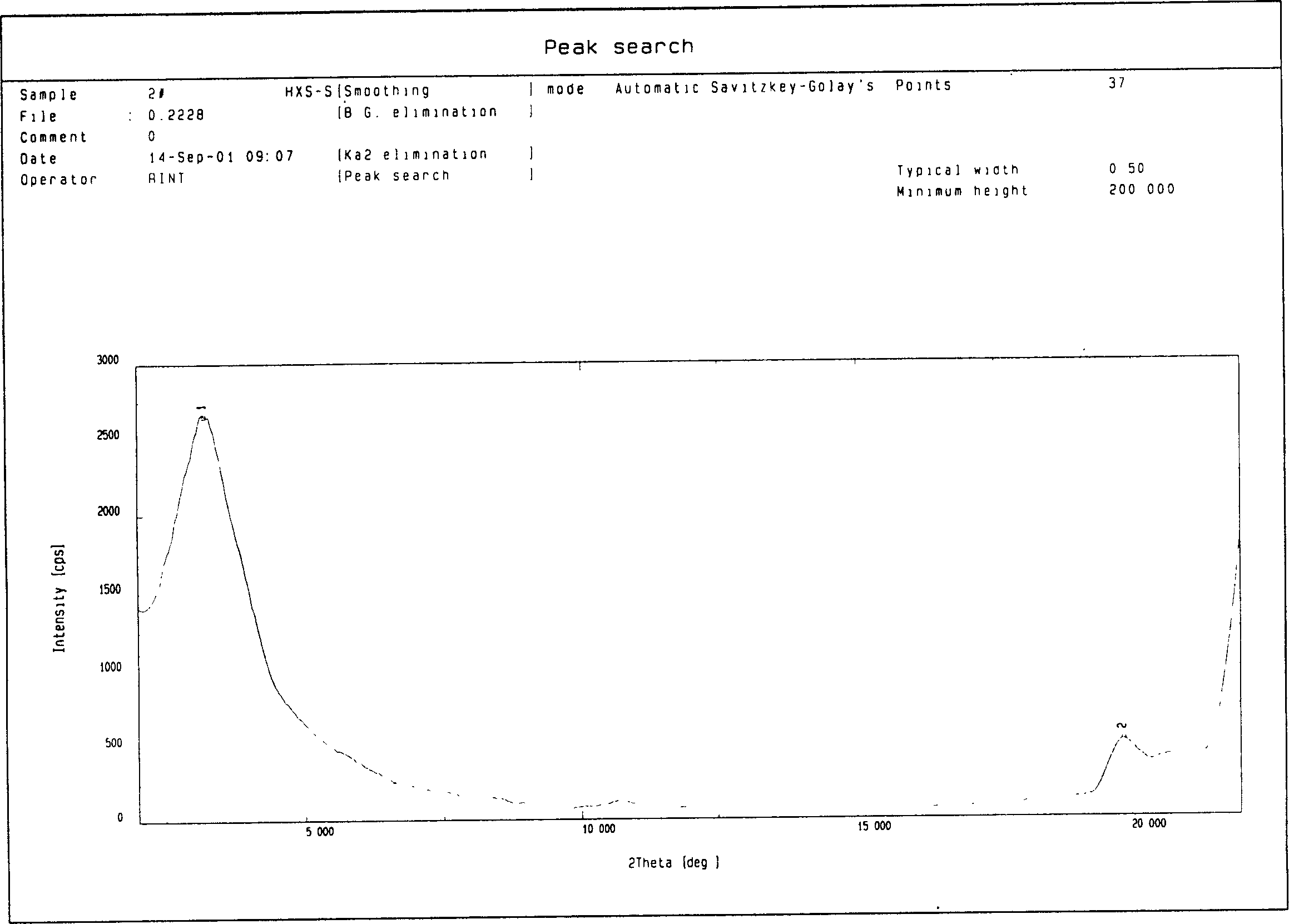

Image

Examples

Embodiment 1

[0027] Preparation of organomontmorillonite:

[0028] Add 190 ml of distilled water to 10 g of sodium montmorillonite, stir to prepare a suspension of sodium montmorillonite with a concentration of 5 wt %, heat and stir to raise the temperature to 70±5° C. To 4.5 g of cetyltrimethylammonium bromide, 4 ml of hydrochloric acid solution with a concentration of 18 wt % was added to prepare cetyltrimethylammonium bromide hydrochloric acid solution. The cetyltrimethylammonium bromide hydrochloric acid solution was slowly added to the above-mentioned 5wt% sodium montmorillonite suspension. Stir and heat to 70±5°C. Heat preservation treatment for 2 hours to prepare organic montmorillonite suspension. The organic montmorillonite suspension is filtered, and the filter cake is washed until there is no chloride ion, so as to obtain the organic montmorillonite slurry. 1.1056 g of the organic montmorillonite slurry prepared above was dried for 2 hours at 105±5° C. to obtain a dry organic...

Embodiment 2

[0045] Preparation of organomontmorillonite:

[0046] Add 190 ml of distilled water to 10 g of sodium montmorillonite, stir to prepare a suspension of sodium montmorillonite with a concentration of 5 wt %, heat and stir to raise the temperature to 70±5° C. To 3.5g of octadecylamine, add 5ml concentration and be the hydrochloric acid solution of 18wt%, make octadecylamine hydrochloric acid solution. The octadecylamine hydrochloric acid solution was slowly added to the above-mentioned sodium montmorillonite suspension with a concentration of 5 wt%. Stir and heat to 70±5°C. Heat preservation treatment for 2 hours to prepare organic montmorillonite suspension. The organic montmorillonite suspension is filtered, and the filter cake is washed until there is no chloride ion, so as to obtain the organic montmorillonite slurry. 1.0896 g of the organic montmorillonite slurry prepared above was dried for 2 hours at 105±5° C. to obtain a dry organic montmorillonite. The concentration ...

Embodiment 3

[0063] Preparation of organomontmorillonite:

[0064] Add 190 ml of distilled water to 10 g of sodium montmorillonite, stir to prepare a suspension of sodium montmorillonite with a concentration of 5 wt %, heat and stir to raise the temperature to 70±5° C. Add 4 ml of 18 wt% hydrochloric acid solution to 7.5 g of distearylamine to prepare a distearylamine hydrochloric acid solution. The distearylamine hydrochloride solution was slowly added to the above-mentioned 5 wt% Na-montmorillonite suspension. Stir and heat to 70±5°C. Heat preservation treatment for 2 hours to prepare organic montmorillonite suspension. The organic montmorillonite suspension is filtered, and the filter cake is washed until there is no chloride ion, so as to obtain the organic montmorillonite slurry. 1.2166 g of the above-prepared organic montmorillonite slurry was dried at 105±5° C. for 2 hours to obtain a dry organic montmorillonite. The concentration of the organic montmorillonite prepared above is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com