Positioning and clamping method for processing piston and processing technique

A piston and positioning surface technology, applied in the field of engine pistons, can solve problems such as unstable shape and position tolerances, engine power reduction, cylinder scuffing accidents, etc., to improve product quality and productivity, eliminate coaxiality errors, and shape and position tolerances stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

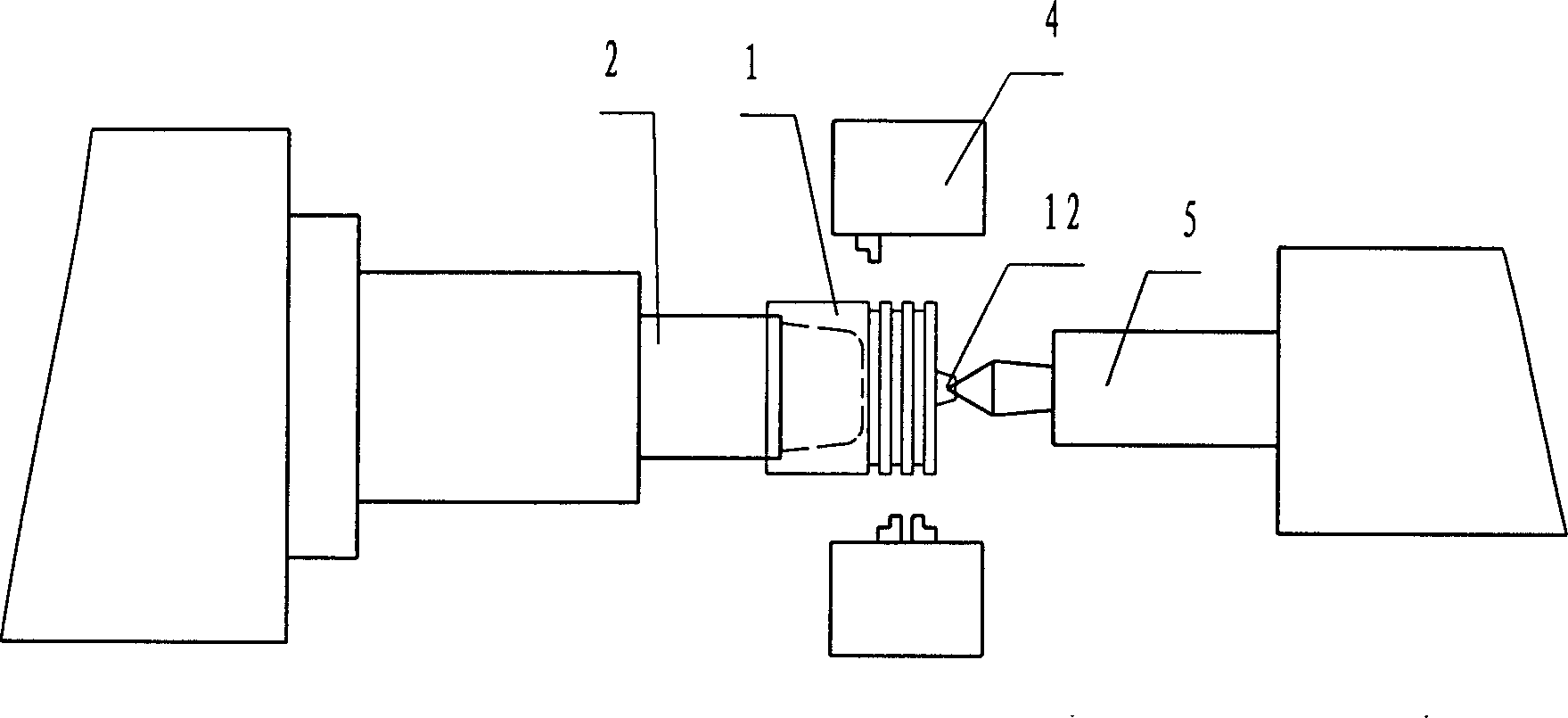

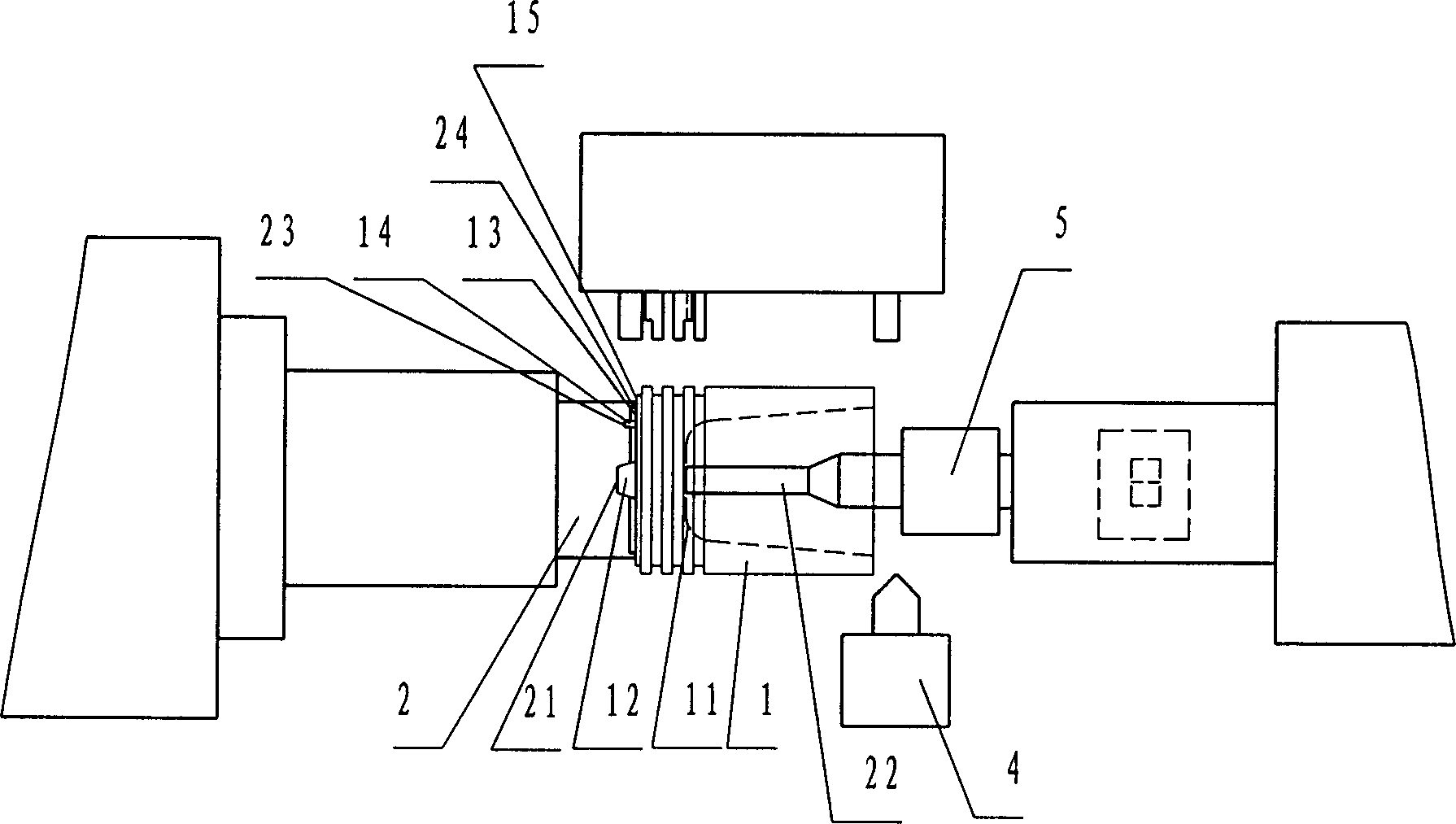

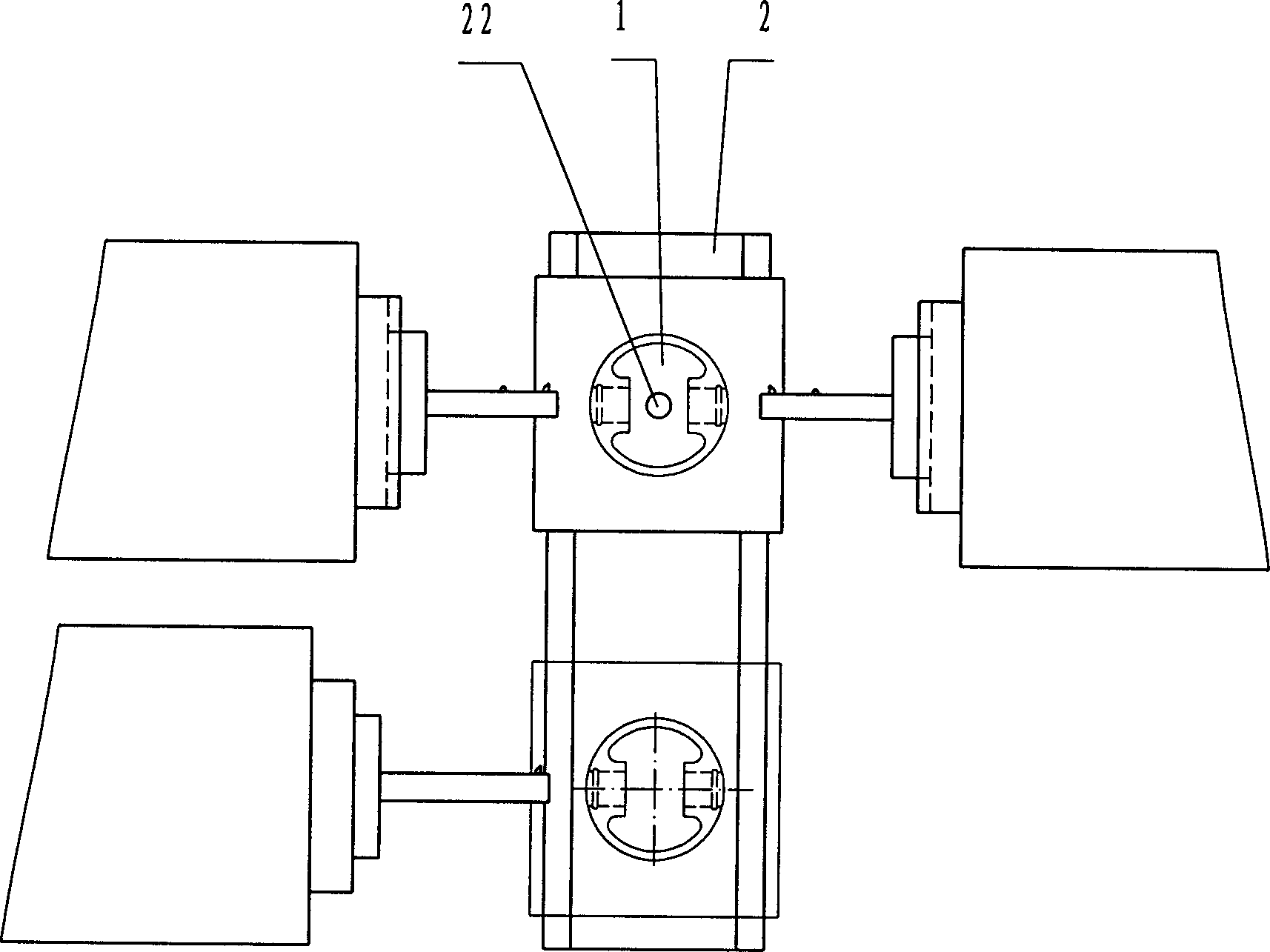

[0016] The utility model is described in detail below in conjunction with the drawings

[0017] The positioning and tightening method for piston processing is as follows: 1) provide processing machine tools; 2) provide processing tools and fixtures 2; 3) use the top 11 of the inner cavity of the piston 1 as the clamping point, and use the outer end surface 13 of the top of the piston and the positioning boss 12 is a positioning surface.

[0018] Compared with the previous processing technology, the piston processing technology arranged by the positioning and tightening method of the piston reduces the number of installations. It includes the following steps: 1) providing processing machine tools; 2) providing processing tools and fixtures; 3) using the outer end surface of the top of the piston and the positioning boss as the positioning surface, with the top of the piston inner cavity as the clamping point, the outer diameter of rough turning---rough and finish turning ring g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com