Yarn Winder

A winding device, a technology for sliver, used in transportation and packaging, folding thin materials, transporting filamentous materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, the present invention will be described in detail with reference to the drawings illustrating a first embodiment of the present invention.

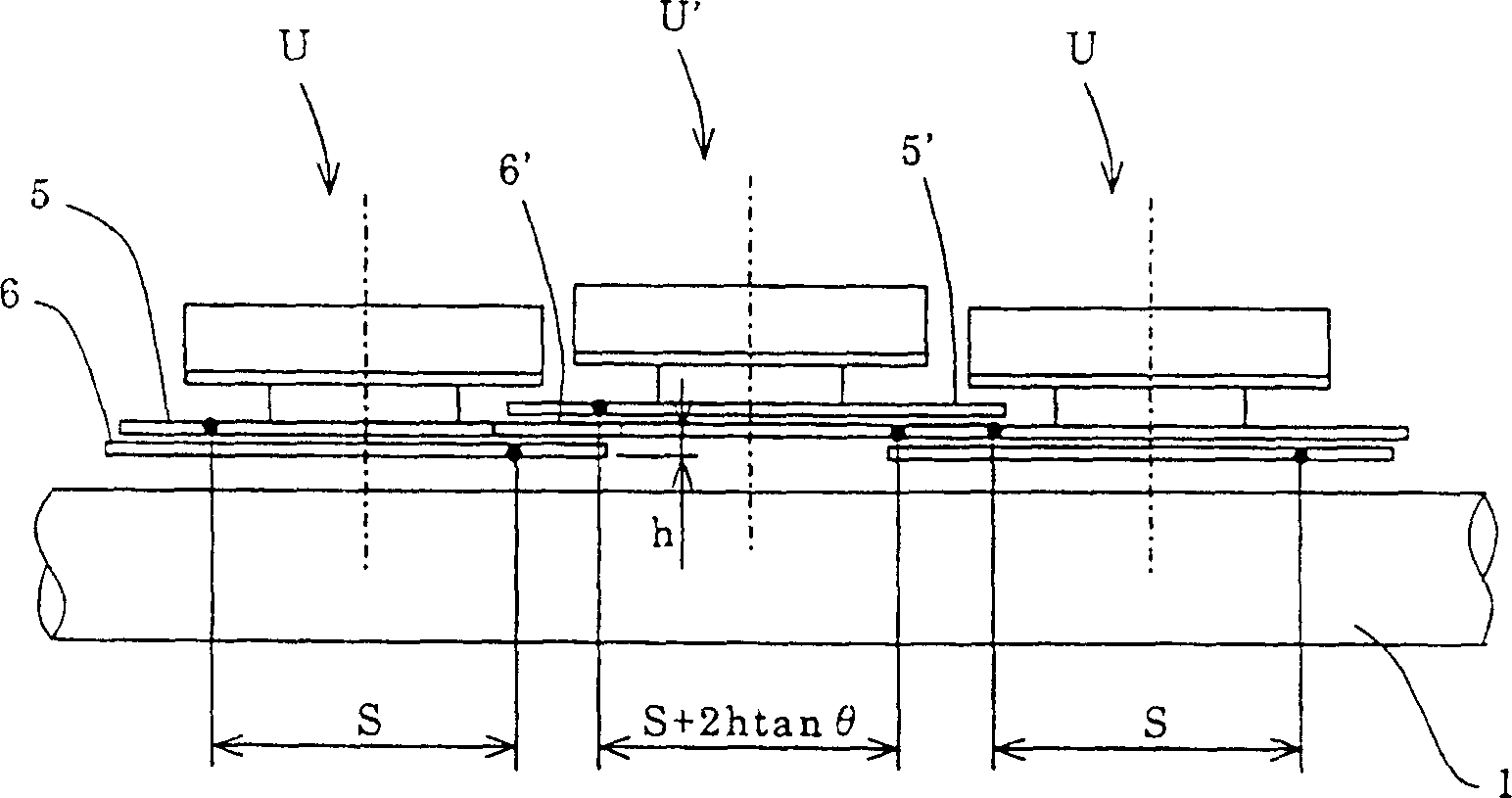

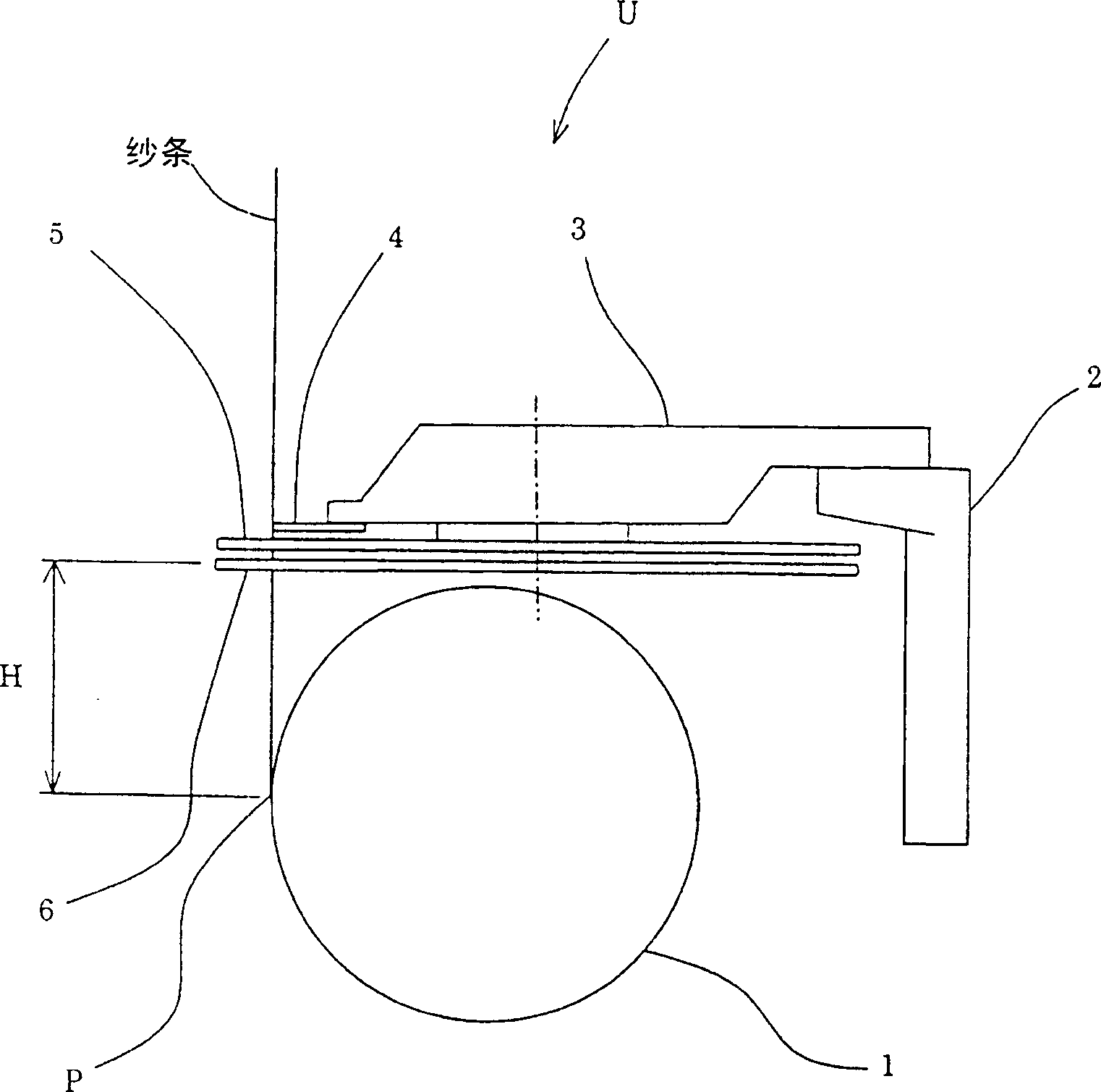

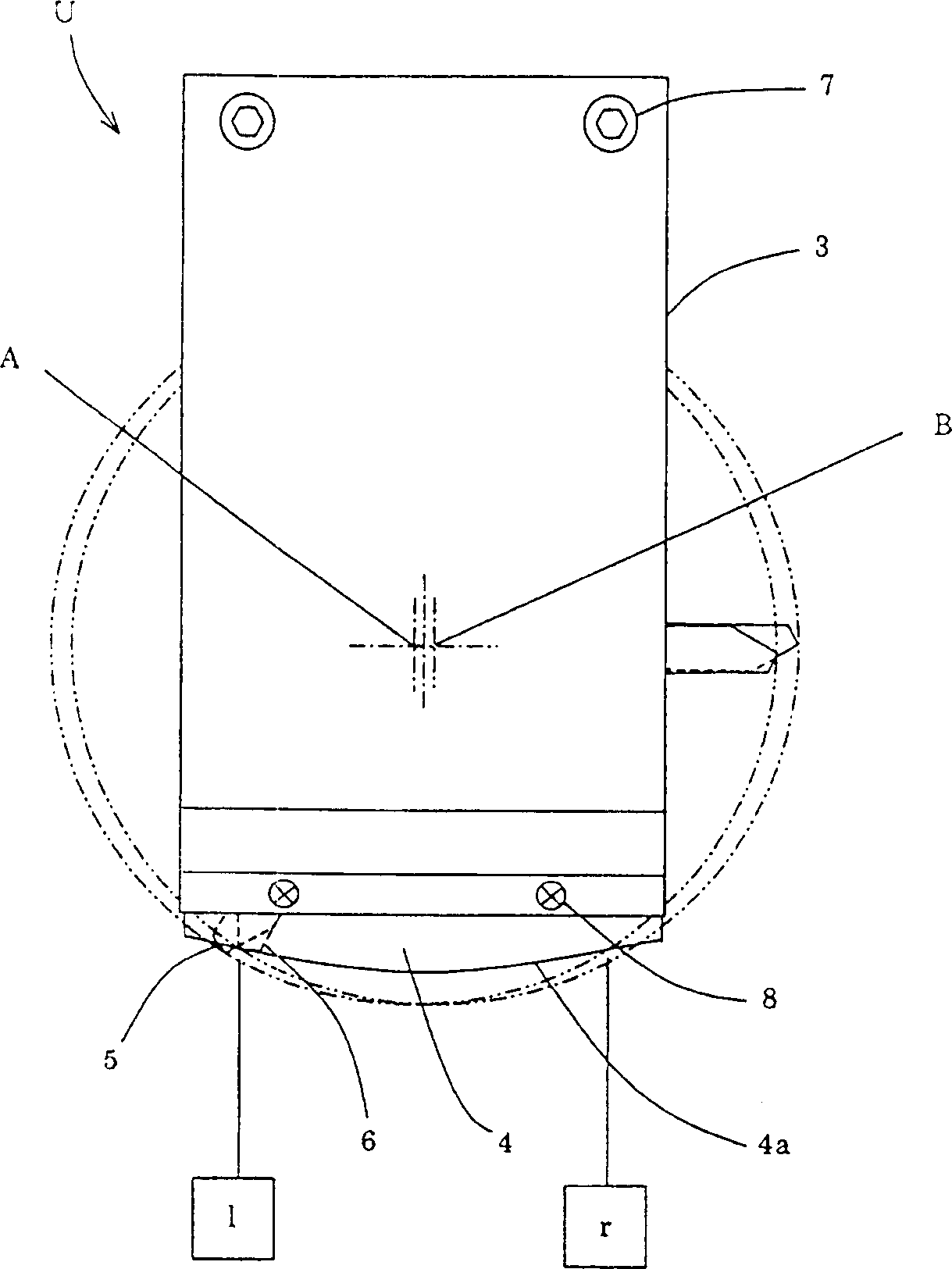

[0036] figure 1 is a front view of the first embodiment of the present invention. figure 2 yes figure 1 side view. image 3 express figure 1 floor plan.

[0037] The contact roller 1 is rotatably supported on the frame 2 by known means not shown in the figures, upstream of the contact roller 1 with respect to the travel path of the sliver, the traversing means U, U' for reciprocating the sliver Alternating horizontal configurations.

[0038] In addition, in this application document, "for each bobbin ... has contact rollers", it is not limited to having a plurality of contact rollers corresponding to each bobbin, but also includes, as in this embodiment, for the traversing devices U, U' adopting The case of a shared touch roll 1.

[0039] In the traversing device U, the configuration in the housing 3 can be ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com