Revolving gear of digging rising arm in digging machine

A technology of rotating mechanism and excavator, which is applied in the direction of mechanically driven excavators/dredgers, etc. It can solve the problems of not being able to rotate at will and not achieve the digging effect, and achieve the effect of convenient operation, simple structure and large rotation radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

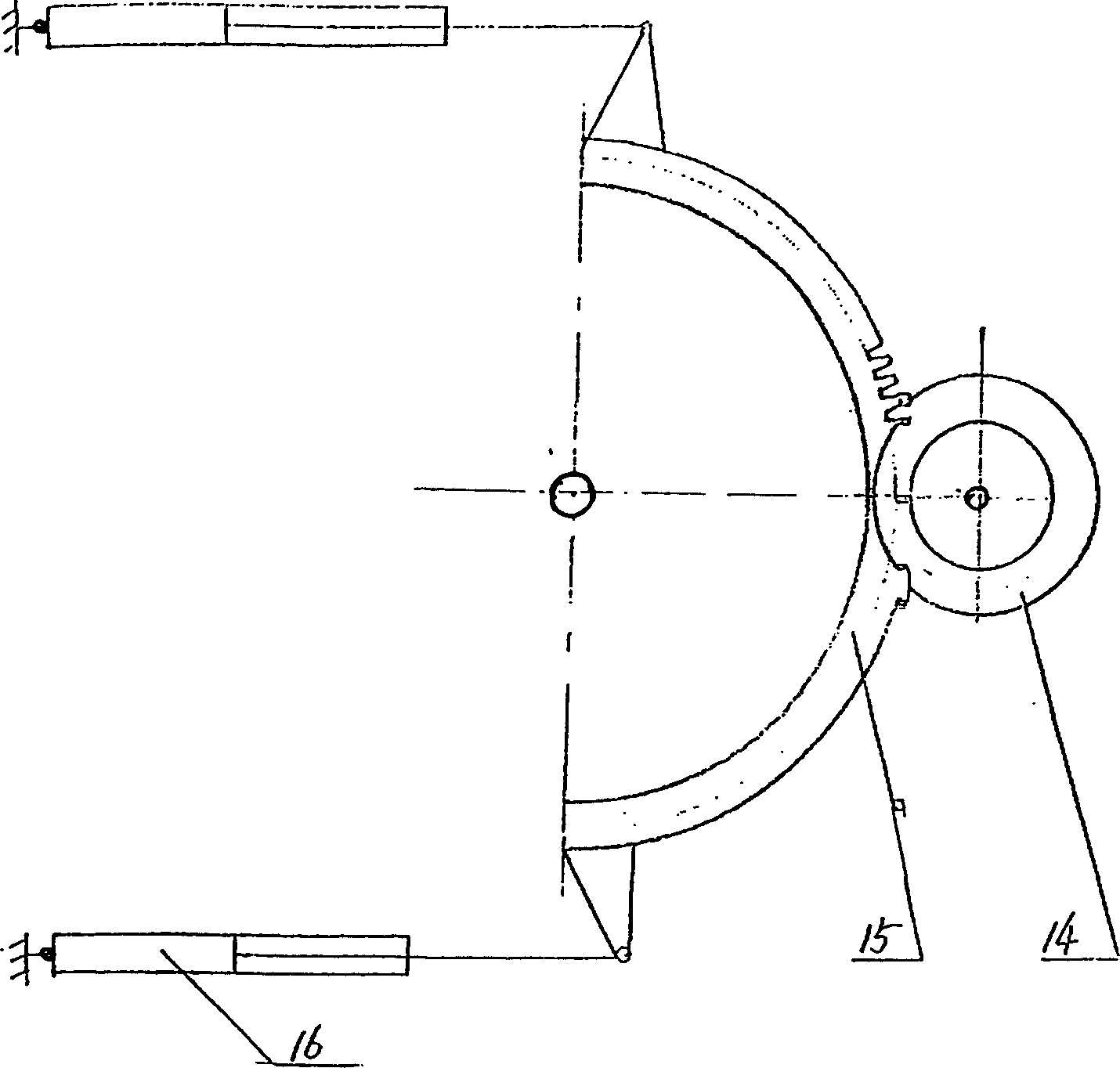

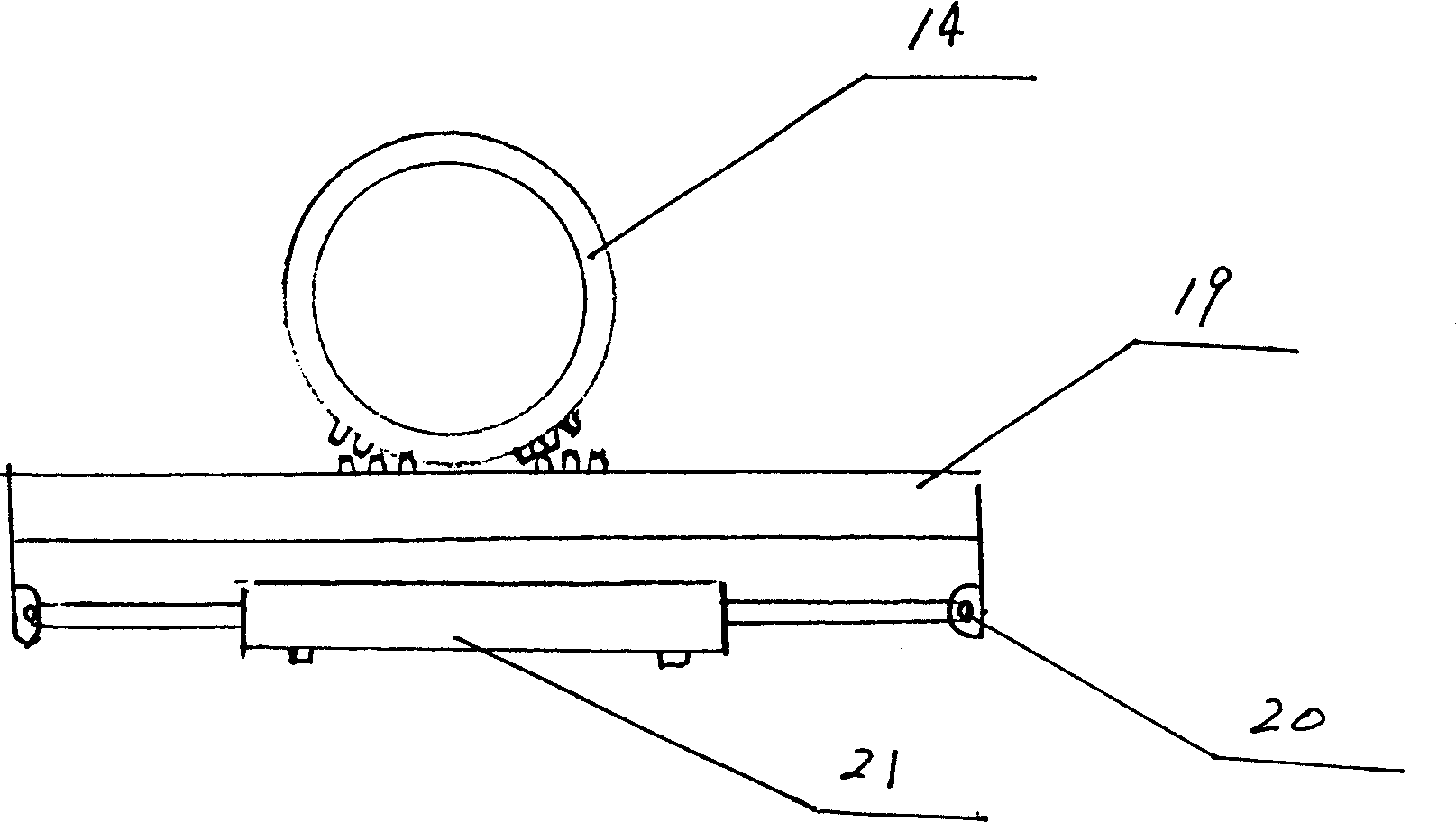

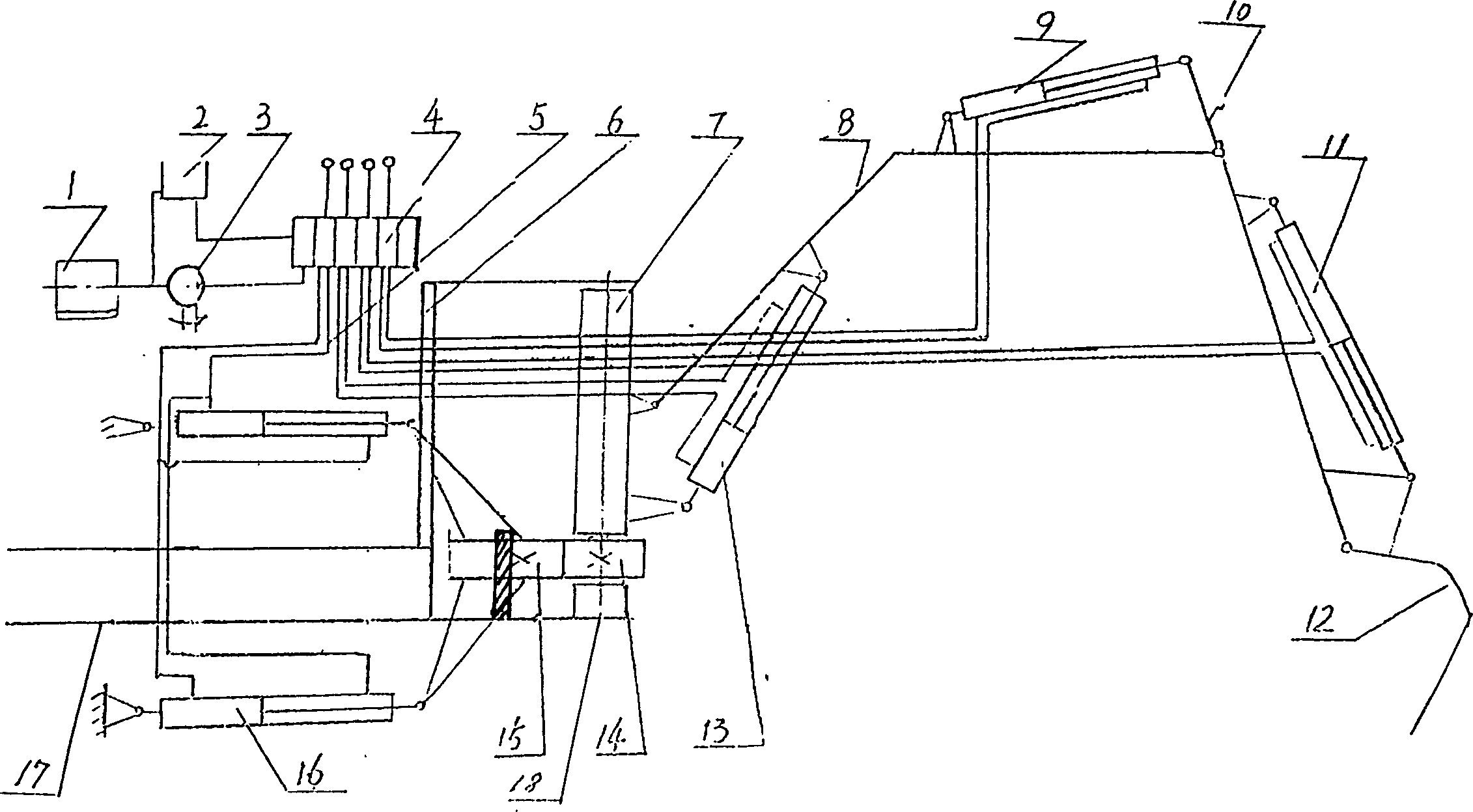

[0013] like figure 1 , 2 As shown in , 3, the present invention includes the digging arm supporting rotating shaft cylinder 7 of the excavator digging arm 8 installed, and the action wheel 14 that drives the digging arm supporting rotating shaft cylinder for rotating motion is fixedly installed on the digging arm supporting rotating shaft cylinder 7, Corresponding to the action wheel 14, a driving device for driving the action wheel 14 to rotate is arranged on the excavator.

[0014] like figure 1 , 3 As shown, in the above mechanism, one of the technical solutions adopted may be: the action wheel 14 is a rotating shaft cylinder gear fixedly installed on the rotating shaft cylinder supporting the digging arm. The driving device that drives the rotating shaft barrel gear 14 to rotate is: a rotating shaft is movably installed on the chassis 17; The rotating shaft barrel gears 14 mesh with each other, and one end of the hydraulic cylinder 16 is hinged on the drive gear 15, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com