Sheet hot sealing device with heat insulating hood

The technology of a heat sealing device and a heat preservation cover is applied in the field of sheet heat sealing devices, and can solve the problems of generating air bubbles, insufficient ability of the roller 31 to maintain the temperature, and long warm-up time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

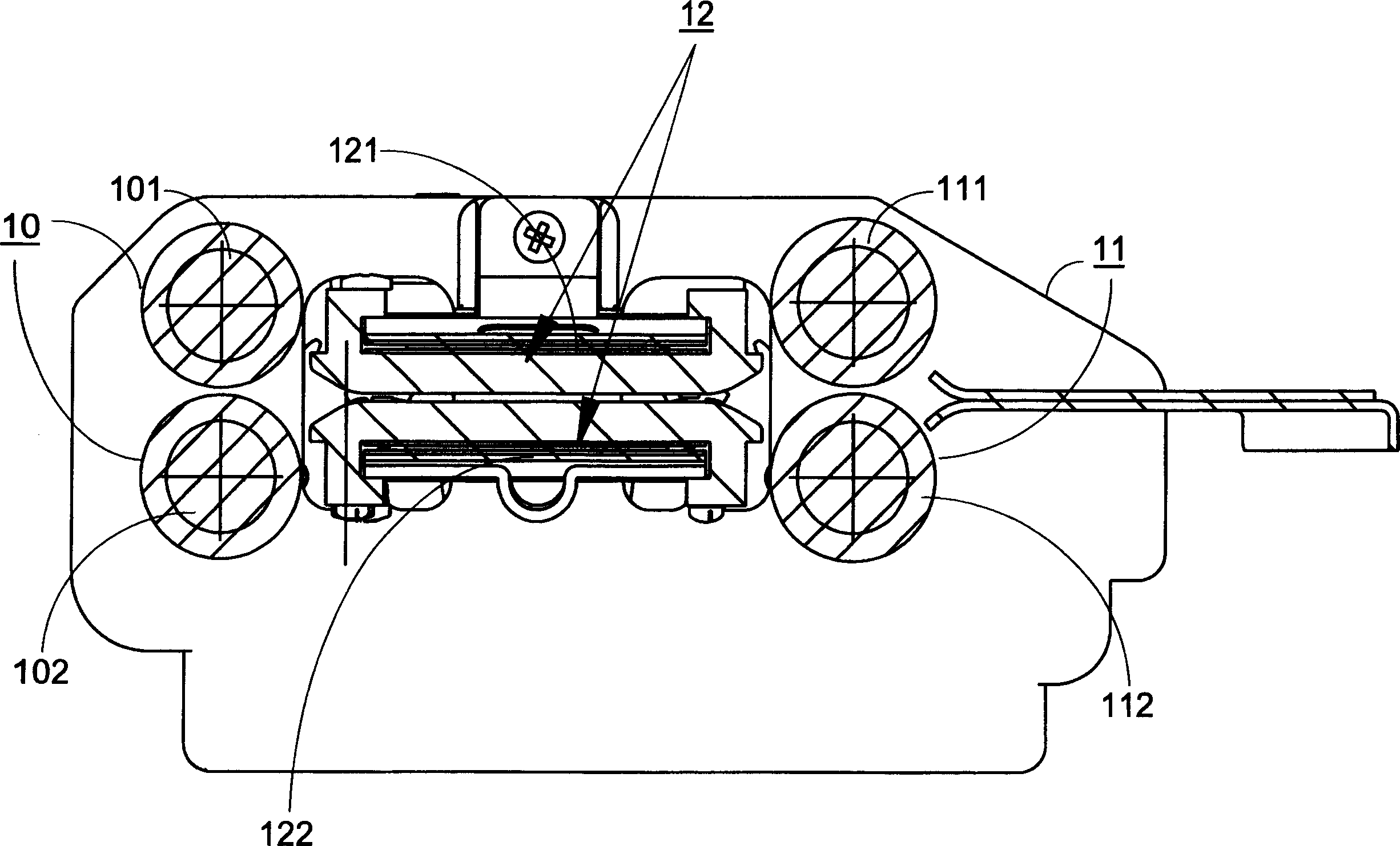

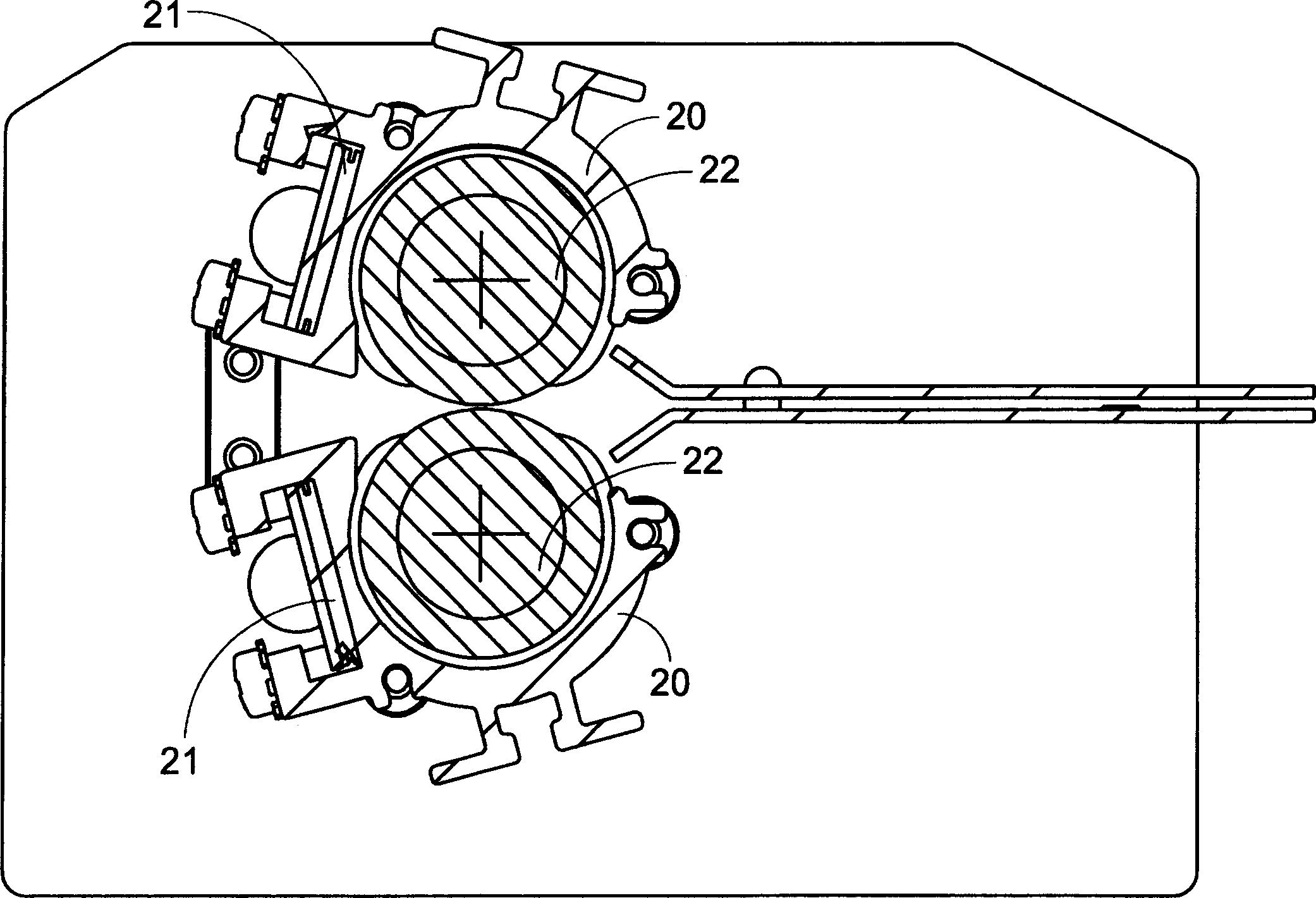

[0019] See figure 2 , is a structural schematic view of a preferred embodiment developed by the present invention to solve common defects, which discloses a sheet heat-sealing device, mainly including a conveying channel 4, which is for several sheets to be heat-sealed (not shown in the figure) , such as two pieces of thermoplastic film and the paper wrapped in between), and the upper and lower sides of the transmission channel 4 are respectively provided with an upper transmission heating and pressing roller 5 and a lower transmission heating and pressing roller 6 (the material of the surface can be rubber completed), wherein the upper transmission heating and pressing roller 5 is composed of a first electrothermal rotating shaft 51 and a first heating and pressing roller 52, and the first heating and pressing roller 52 is covered on the first electrothermal rotating shaft 51 Externally, the electrothermal shaft 51 converts electrical energy into thermal energy and rotates, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com