Cone breaker device

A technology for shredding paper and paper pieces, which is applied in the field of shredding devices and can solve problems such as troubles in use, paper jams, and unsmooth shredding action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

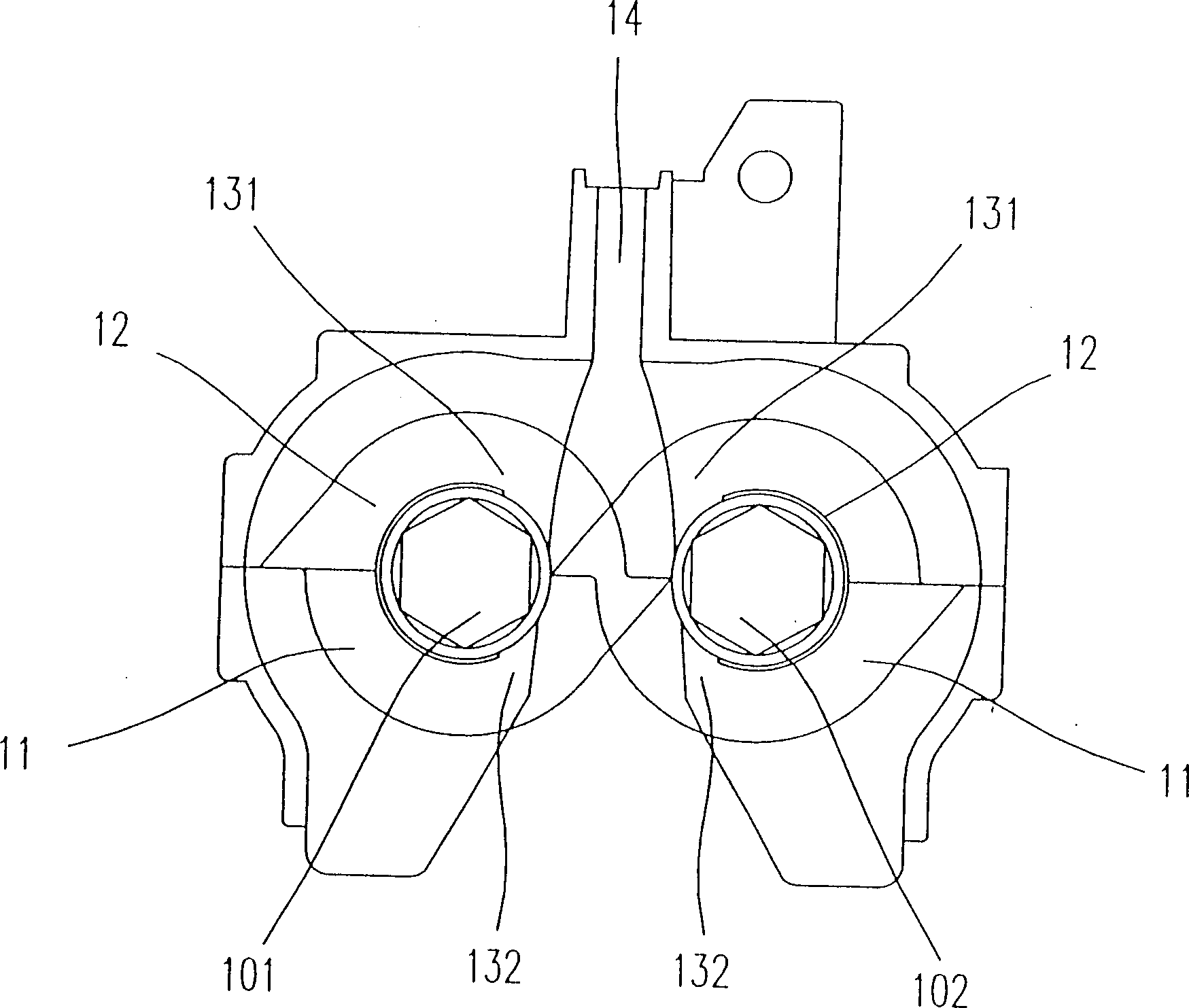

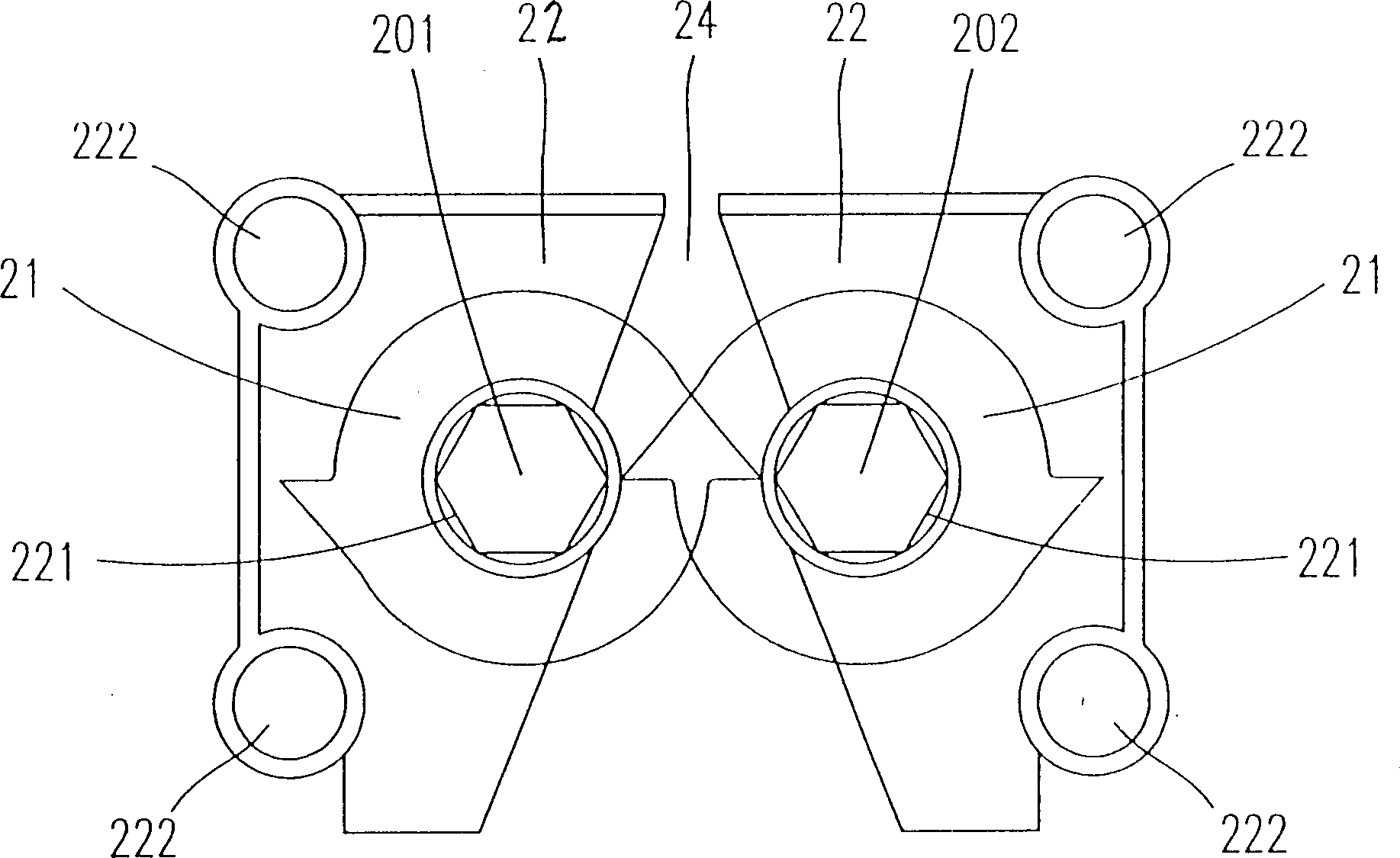

[0020] See figure 2 As shown, it is a schematic cross-sectional view of a preferred embodiment of the shredding device of the present invention. It can be clearly seen from the figure that a shredded paper channel 24 is formed between the first shaft 201 and the second shaft 202 arranged in parallel to provide a passage of paper to be shredded; A plurality of cutting blades (cutters) 21 on the two shafts 202 are directly separated by a gap paper guide 22 with a gap space. And the cutting blade (cutter) 21 that is fixedly fitted on the first shaft 201 and the second shaft 202 can be driven by the first shaft and the second shaft to rotate respectively, and then pass through the shredding passage. 24 of the shredded paper to be cut.

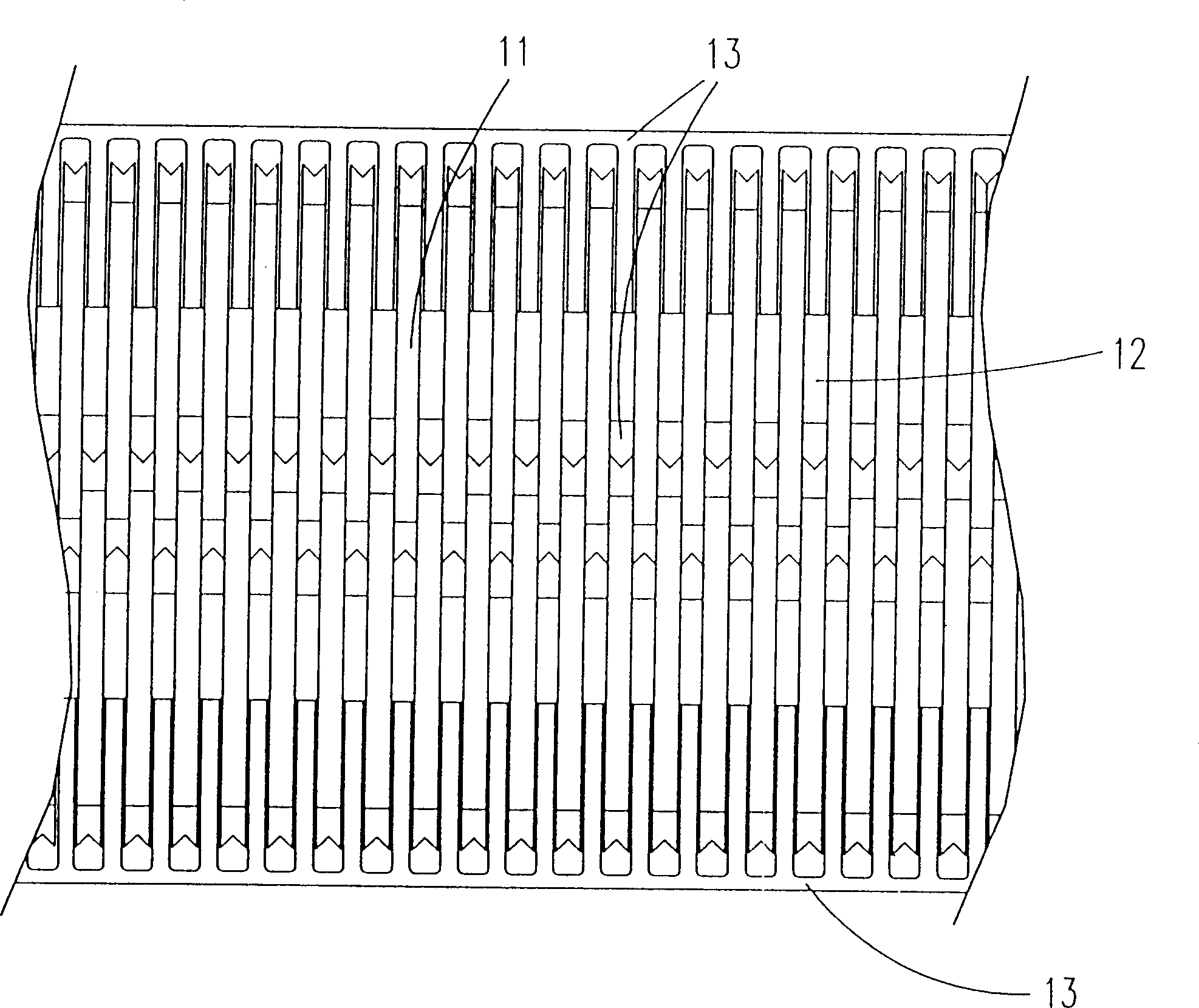

[0021] see you again Figure 3A , 3B As shown, it is a schematic diagram of the appearance structure of the gap paper guide sheet 22 of the present invention, which is manufactured in an integrated manner, and its material can be plastic or me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com