Supersonic technological method and apparatus for preparing nano material

A technology of nanomaterials and ultrasonic technology, which is applied in the field of nanomaterials prepared by ultrasonic technology, can solve the problems of safety and stability hindering production scale, complex supplementary processing requirements for post-processing, and lack of versatility, so as to achieve easy operation and strengthening Effect of emulsification and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

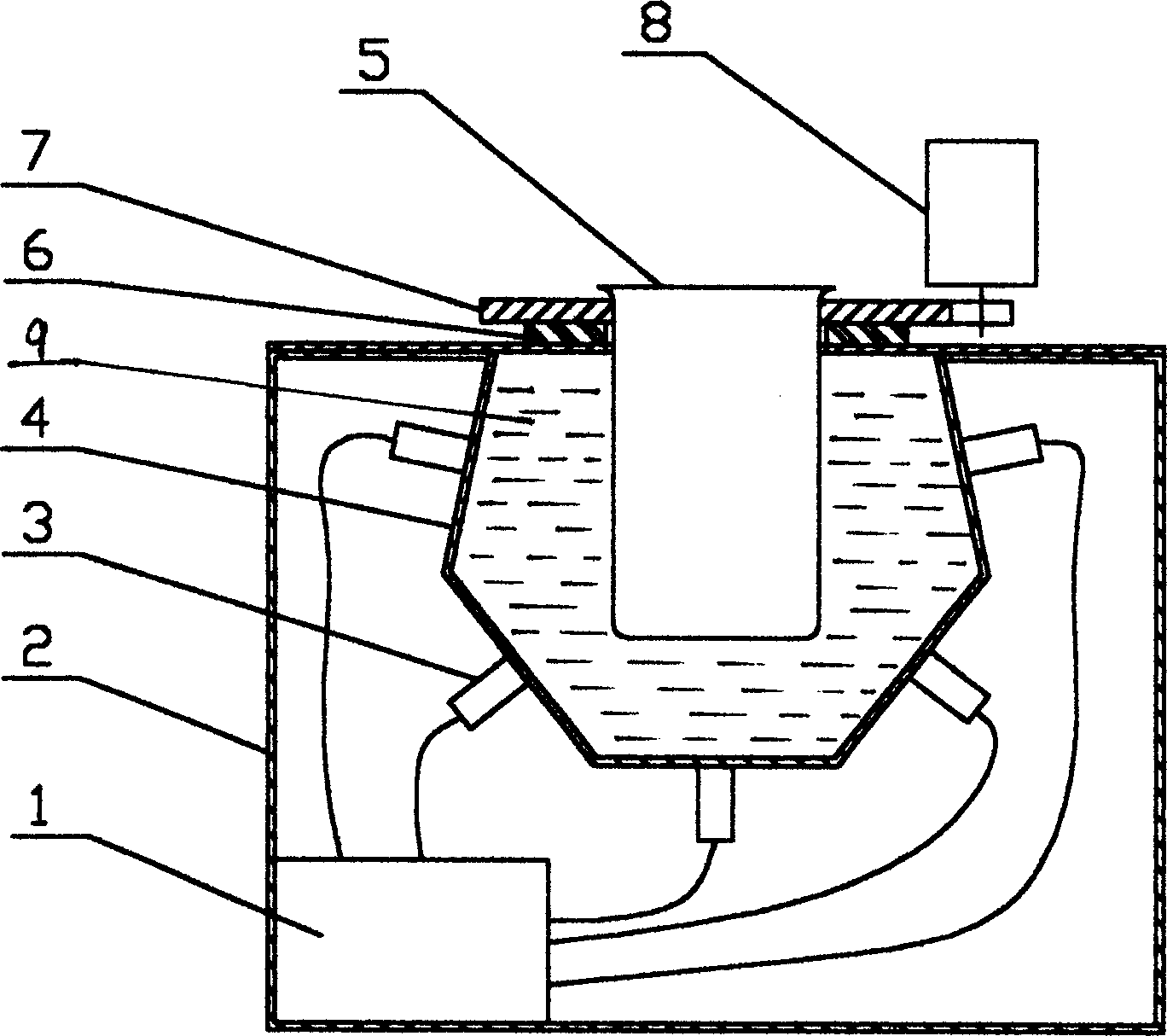

[0027] A supersonic function tank body 4 is manufactured with a high-quality stainless steel plate. The shape of the tank body is a 9-hedron.

[0028] Install ultrasonic transducers 3 on each side and bottom of the tank body 4, so that each ultrasonic transducer 3 can focus and irradiate ultrasonic energy to the center of the tank body 4, and the working frequency of each transducer is adjustable from 10 to 120KHz .

[0029] There is an ultrasonic generator 1 inside the support 2 , and the ultrasonic generator 1 is connected to each ultrasonic transducer 3 .

[0030] A reaction vessel 5 is made by using optimized pure hard glass, and the reaction vessel 5 is placed in the center of the tank body 4 .

[0031] The upper opening of the reaction vessel 5 is provided with a mechanism to make it rotate: a bearing 6 , a rotating wheel 7 and a motor 8 .

[0032] The gap between the functional tank 4 and the reaction vessel 5 is filled with water 9 .

[0033] Prepare the equipment a...

Embodiment 2

[0035] Prepare equipment according to embodiment 1, prepare appropriate dilution concentration ZnSO in reactor 5 4 solution, put it into an ultrasonic device to keep it at a constant temperature of 80°C, and turn on the ultrasonic generator 1 and the stirring device, and slowly add Na 2 CO 3 , the above two salts were subjected to metathesis reaction for 1.5h under ultrasonic irradiation to obtain ZnCO 3 ; Wash with deionized water at 100°C to remove Na in the system + with SO 4 2- ions, and then washed with pure anhydrous ethanol for 0.5h under the condition of ultrasonic irradiation, and then dried in a flash machine at 125°C with the addition of dispersant to obtain nano-zinc oxide with a particle size of 65-120nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com