Method for isoalting oil soot by air jet layer and its oil soot exhauster

A technology of air jet and range hood, which is applied in the direction of removing oil fume, application, household stove, etc., can solve the problems of dripping oil containing harmful substances, endangering human health, wasting water resources, etc., so as to reduce pollution, reduce labor intensity and save energy. effect of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

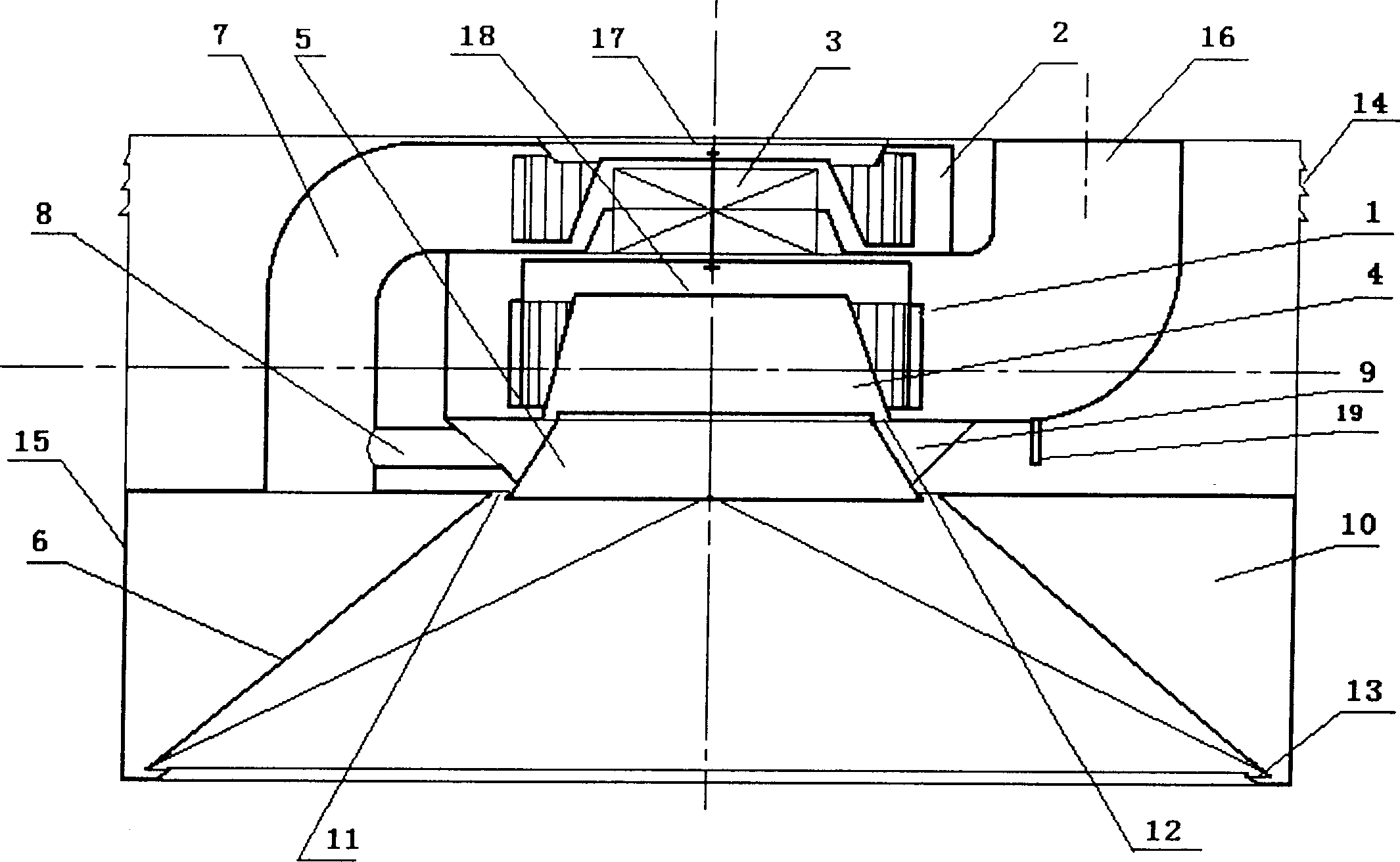

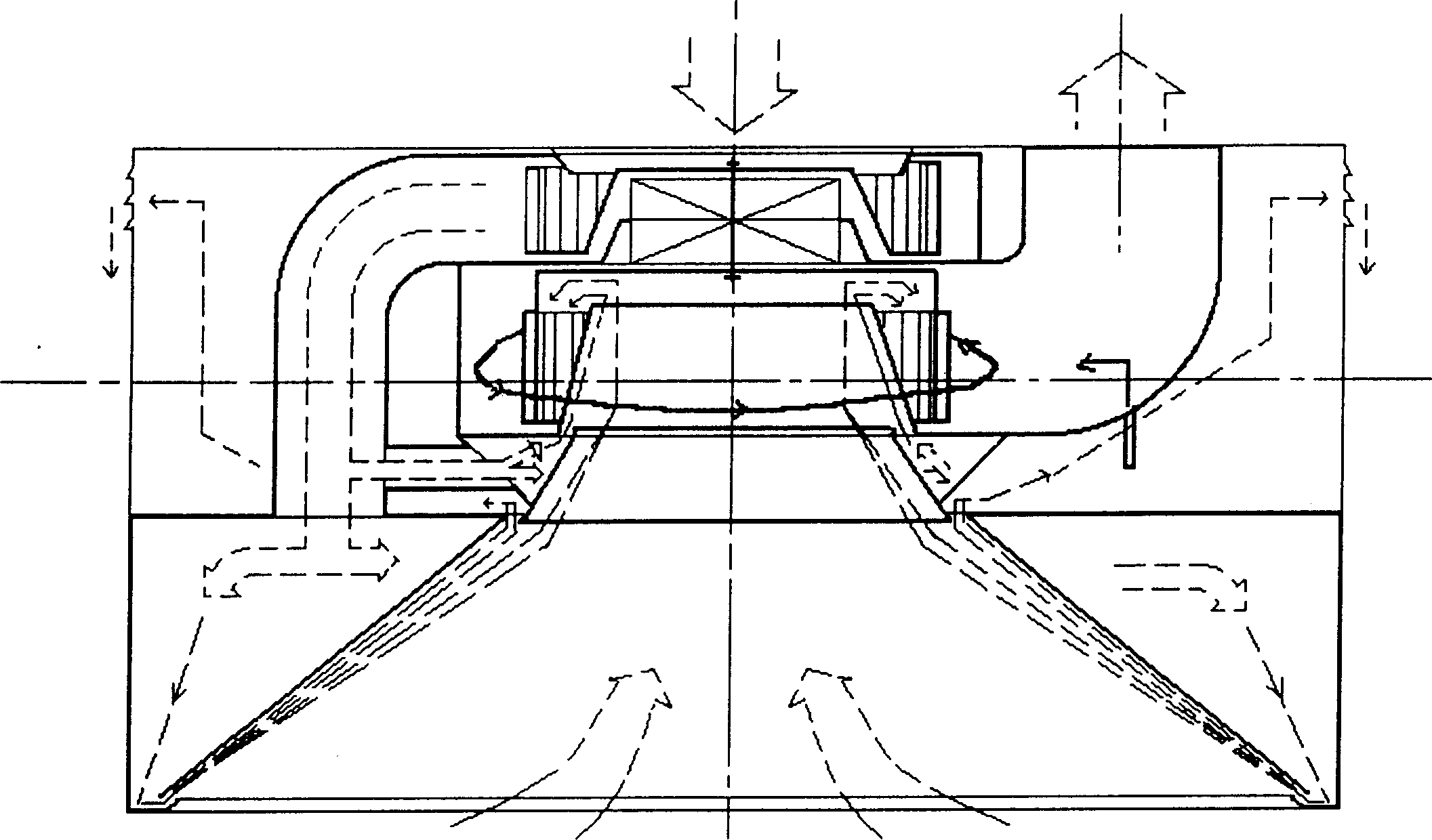

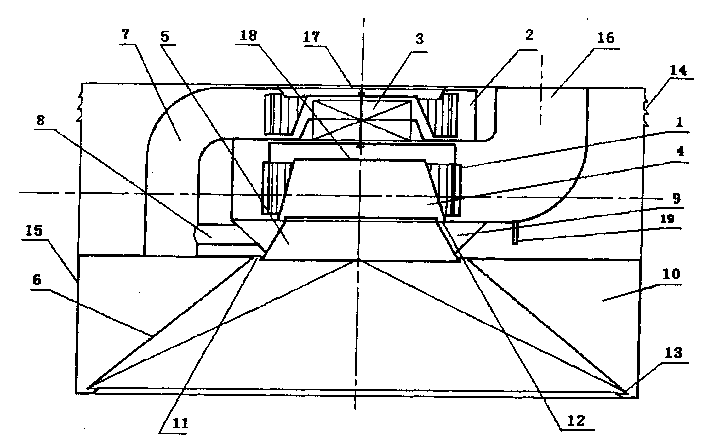

[0018] Embodiment: a kind of method (see figure 1 ), which is characterized in that an air jet isolation layer is formed on the entire inner cavity surface of the range hood to form a layer of isolation and block the contact and adhesion of oil fume particles and the inner cavity surface of the range hood.

[0019] The above-mentioned flow trend of the air jet isolation layer formed on the entire inner cavity surface of the range hood can be from bottom to top along the entire inner cavity surface of the range hood (see figure 1 ).

[0020] A range hood with an air jet insulation layer (see figure 2 ), a range hood with an air jet isolation layer, including a smoke collection hood 6, a centrifugal fan I1 and a motor 3, the centrifugal fan I1 has a fume outlet 16 and communicates with the smoke collection hood 6 and is connected to the motor 3 at the same time, its characteristics It is to install a current collector between the said smoke collecting hood 6 and the centrifug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com