Repairing method and repairing pipe structure for partially dug old pipeline with stainless lining

A technology of local excavation and repair method, applied in the direction of pipes/pipe joints/pipes, pipe components, mechanical equipment, etc. Increased corrosion life, high strength, and beneficial effects on human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

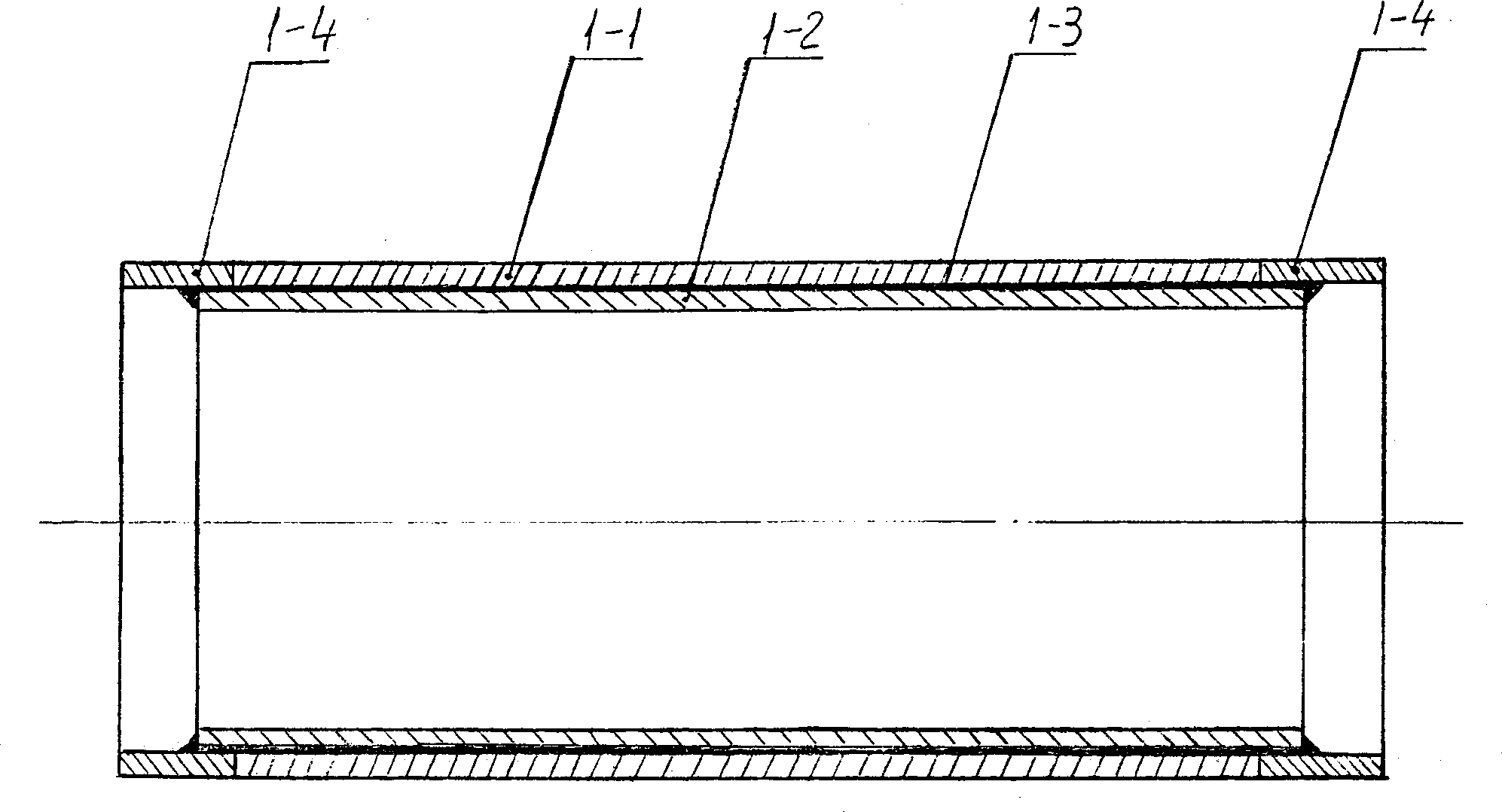

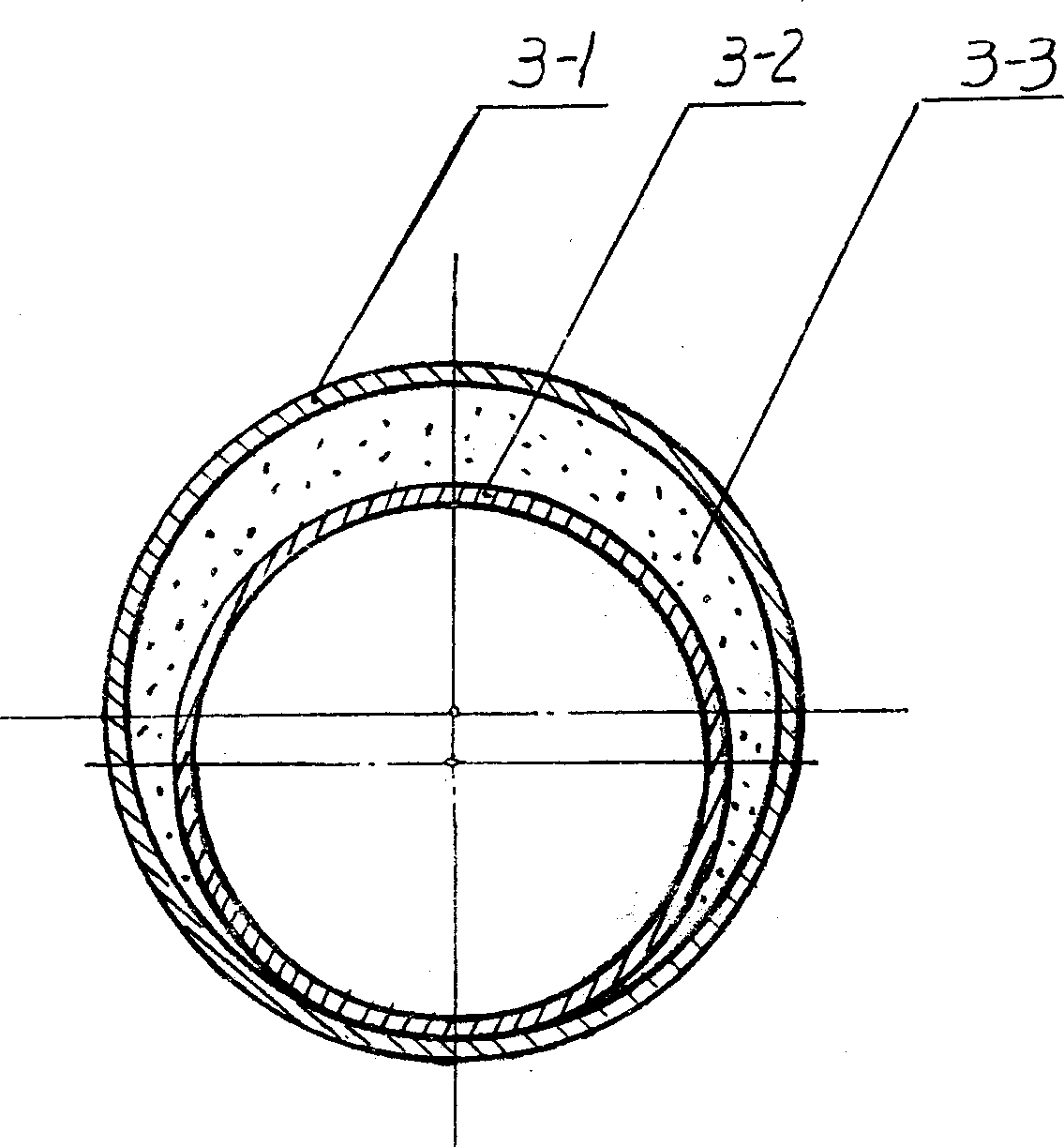

[0053] 1. Use the vertical operation well to repair the old pipeline made of carbon steel pipe, the carbon steel pipe is 73×5.5mm, the stainless steel lining pipe is made of 304 stainless steel, the size is 61×0.4mm, and the segment length is 9-20m. After shrinking, the size is 59-60mm. Put it into the old carbon steel pipe and seal it. Use gasoline and oxygen mixture to explode the diameter. After the diameter of the stainless steel lined pipe is expanded, the inner wall is smooth and checked by 20MPa water pressure. There is no leakage and meets the original requirements. Technical requirements for carbon steel pipes.

[0054] 2. Use the vertical operation well to repair the 300×40mm cement pipe. The interior is lined with a stainless steel lining pipe made of 304 stainless steel. The size is 280×0.5mm and the length is 80m. After it is placed in the cement pipe, the cement pipe and stainless steel Put a number of equidistant cards between the lining pipes, the distance betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com