Particulate burning purifying catalyst

An oxidation catalyst and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, dispersed particle separation, etc., can solve the problems of fuel consumption reduction, particle filter deterioration, and large exhaust gas pressure loss And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

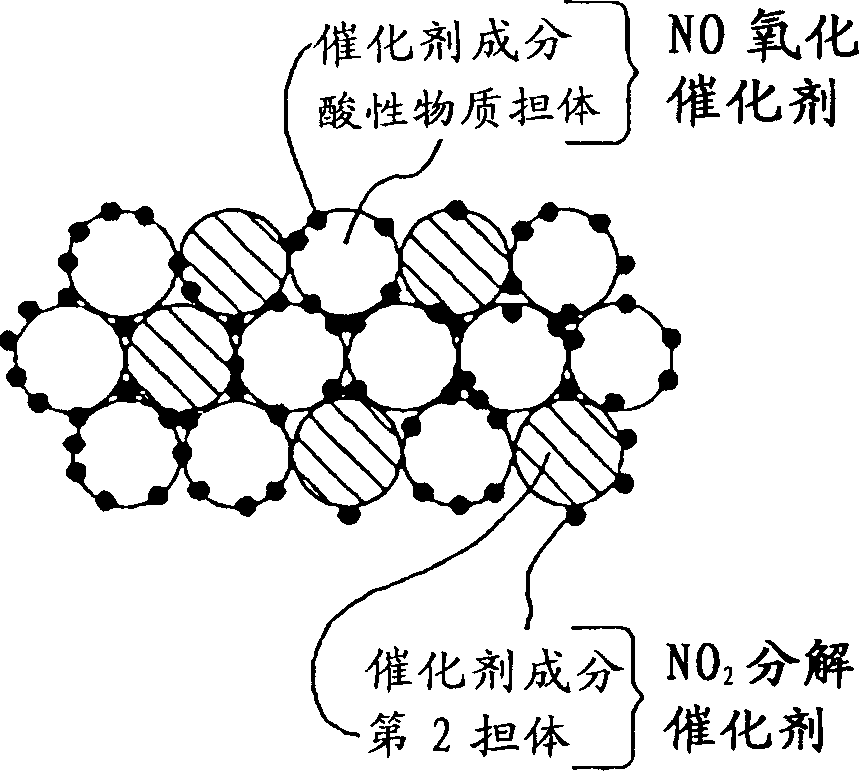

[0047] Add 20 parts by mass of WO to 91 parts by mass of zirconium hydroxide powder 3 The conversion concentration is 50% by mass of ammonium metatungstate aqueous solution, mixed and dried at 80°C overnight, then sintered at 650°C for 2 hours to obtain tungstic acid / zirconia (WO 3 / ZrO 2 )powder.

[0048] In addition, 85 parts by mass of 40% by mass barium acetate aqueous solution was added to 100 parts by mass of γ-alumina powder, mixed, dried overnight at 80°C, and then sintered at 500°C for 1 hour to obtain Ba / γ-alumina powder.

[0049] In these WO 3 / ZrO 2 To 100 parts by mass of powder and 100 parts by mass of Ba / γ-alumina powder, 60 parts by mass of aluminum nitrate solution with a concentration of 40 mass%, 40 parts by mass of ceria-zirconia powder, and 200 parts by mass of water were added, and mixed with a ball mill 8 hours.

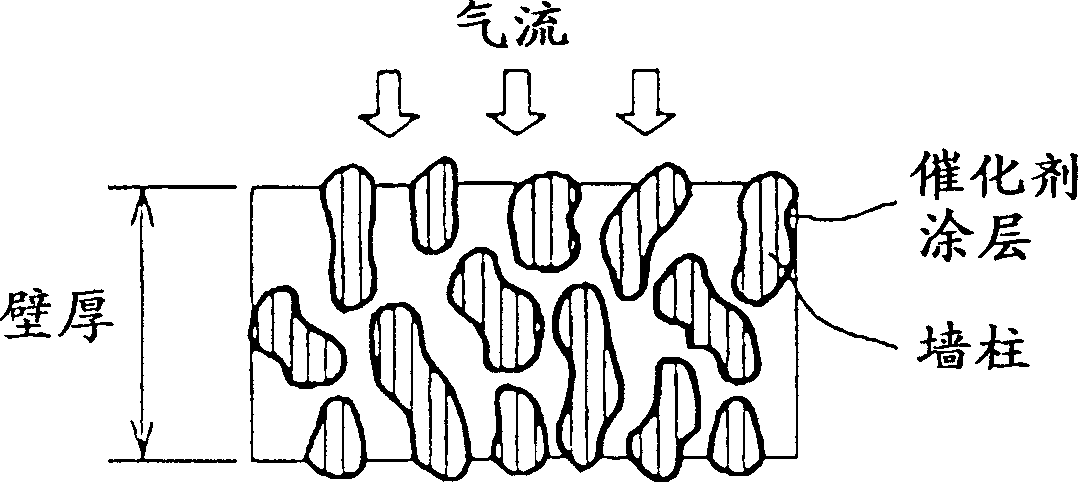

[0050] The resulting slurry is coated on the monolithic substrate, dried and sintered at 650°C for 1 hour to form a WO containing WO on t...

Embodiment 2

[0053] Obtain WO equally with embodiment 1 3 / ZrO 2 powder.

[0054] On the one hand, 5 parts by mass of Fe was impregnated with respect to 100 parts by mass of γ-alumina powder, dried overnight at 80°C, and then sintered at 500°C for 1 hour to obtain Fe / γ-alumina powder.

[0055] In these WO 3 / ZrO 2 To 100 parts by mass of powder and 100 parts by mass of Fe / γ-alumina powder, 60 parts by mass of aluminum nitrate solution, 40 parts by mass of ceria-zirconia powder, and 200 parts by mass of water were added in the same manner as in Example 1, and mixed by a ball mill 8 hours.

[0056] The resulting slurry is coated on the monolithic substrate, dried and sintered at 650°C for 1 hour to form a WO-containing substrate on the monolithic substrate. 3 / ZrO 2 powder and layers of Fe / γ-alumina powder.

[0057] Then, impregnate dinitrosated diammine Pt aqueous solution and Rh nitrate aqueous solution in the same manner as in Example 1, and sinter at 500° C. for 1 hour to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com