Coke-pushing process automatic management system

A process automation and management system technology, applied in the field of coke pushing process automation management system, can solve the problems of signal processing lag, inability to achieve multi-point synchronous real-time monitoring, etc., and achieve the effect of small maintenance, automatic management, and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment, the present invention is described in further detail as follows:

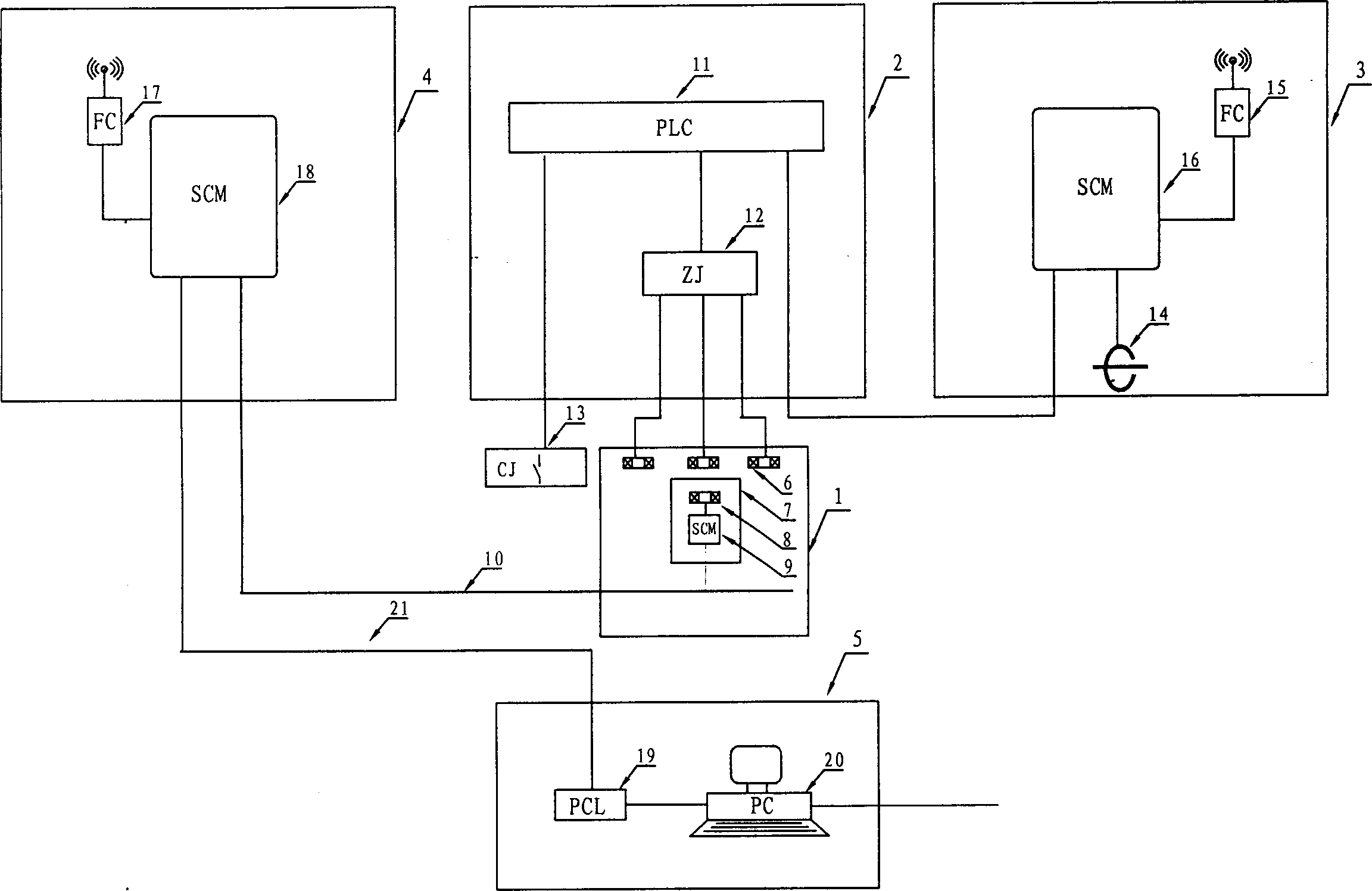

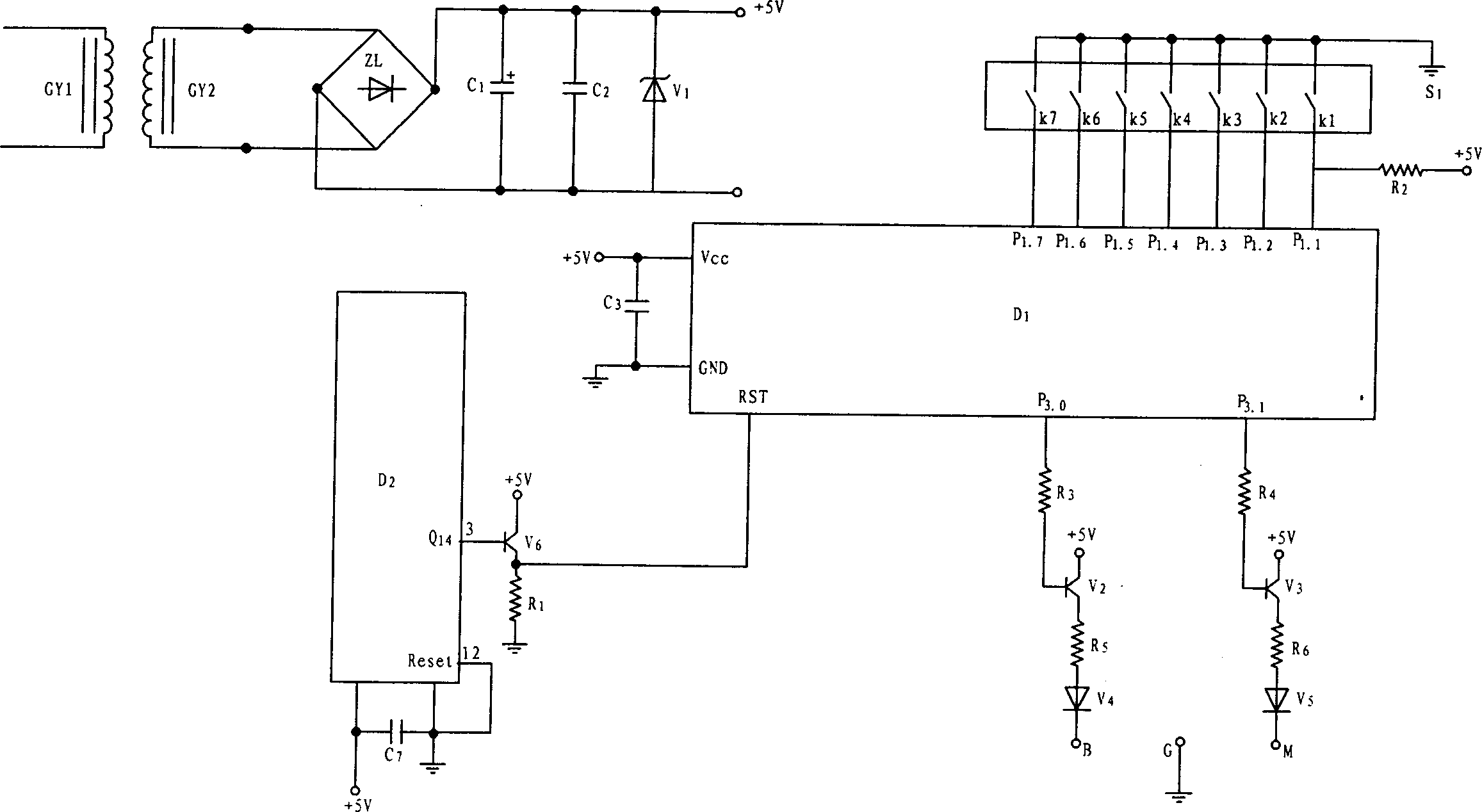

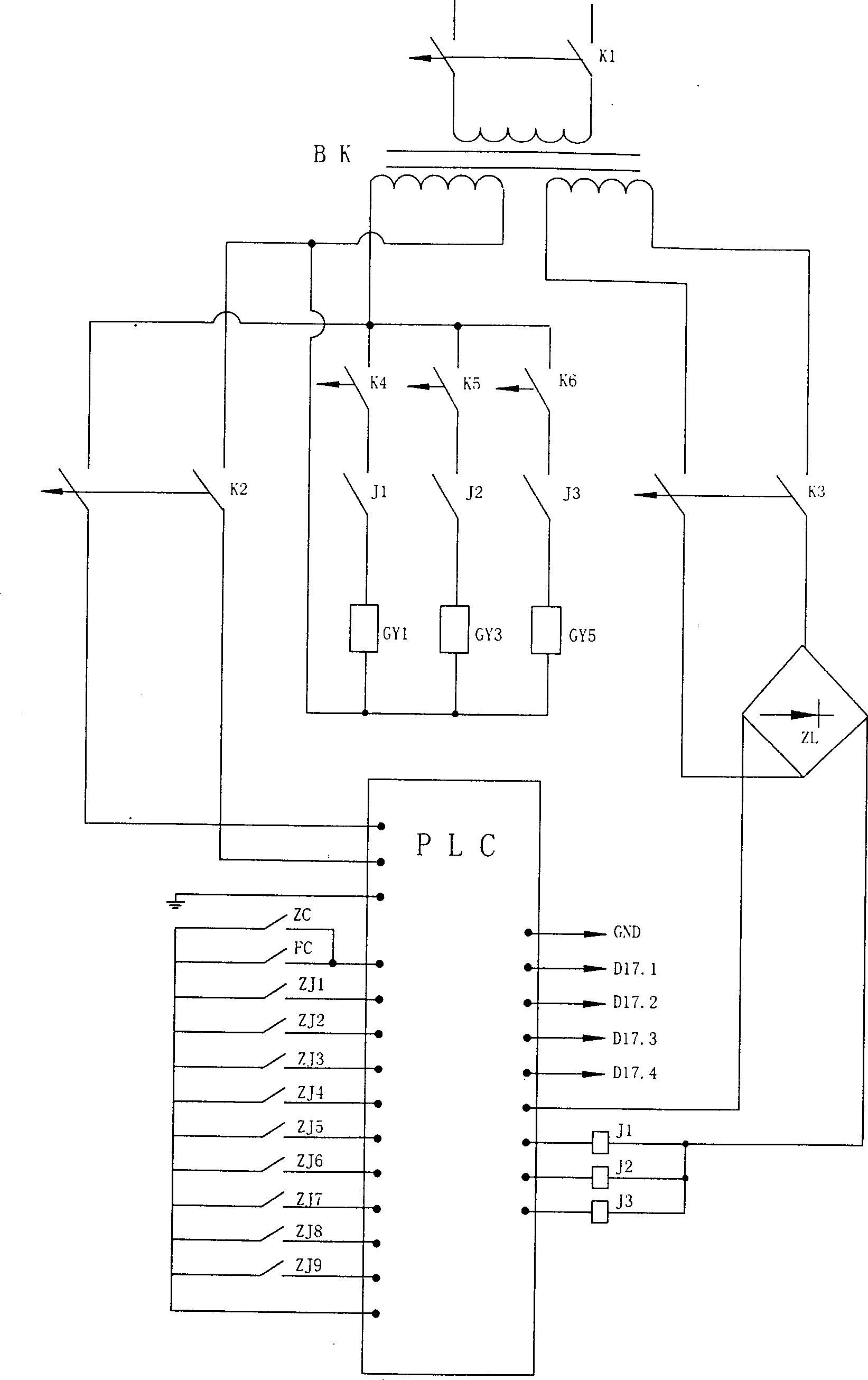

[0016] Such as figure 1 As shown, in the furnace number automatic generation and identification device 1, the furnace number sensor 6 is composed of a coil with an iron core, installed on the corresponding frame of the coke pushing car sliding door, coke pushing, and flat coal mechanism, and connected with the The furnace number excitation control device 2 is connected to the intermediate relay 12, and the furnace number generator 7 is composed of an induction coil 8 and a furnace number address board 9 connected to each other through wires, and is installed at the position corresponding to the coke oven carbonization chamber beside the coke pushing car track , and is connected to the single-chip microcomputer circuit 18 of the ground communication control device 4 through the furnace number address bus 10; the furnace number generator 7 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com