Radiation testing device and radiation testing method

A technology for inspection devices and inspection methods, which can be applied to irradiation devices, measurement devices, nuclear radiation exploration, etc., and can solve problems such as high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

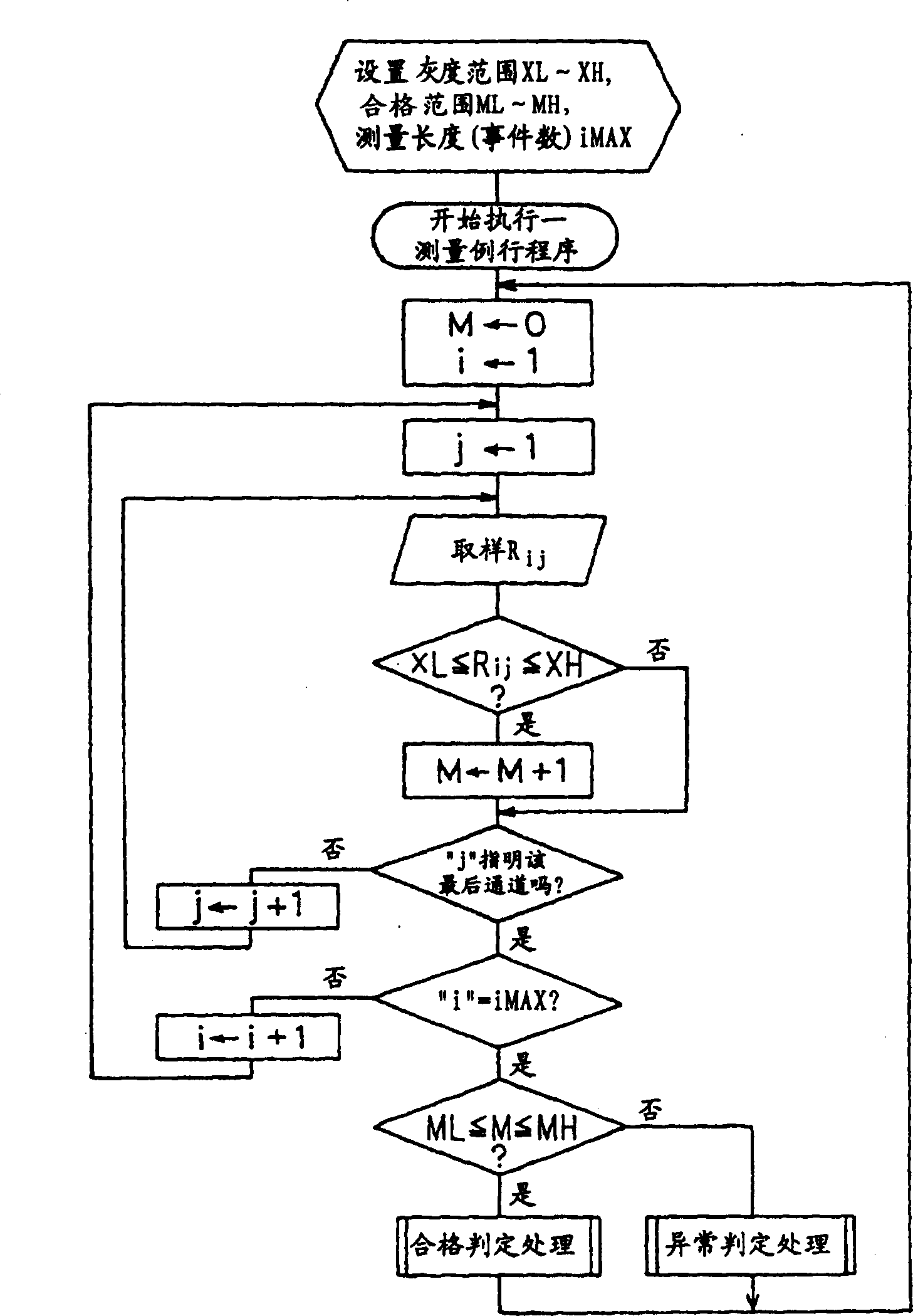

[0017] An embodiment of the present invention will be described below in conjunction with the accompanying drawings.

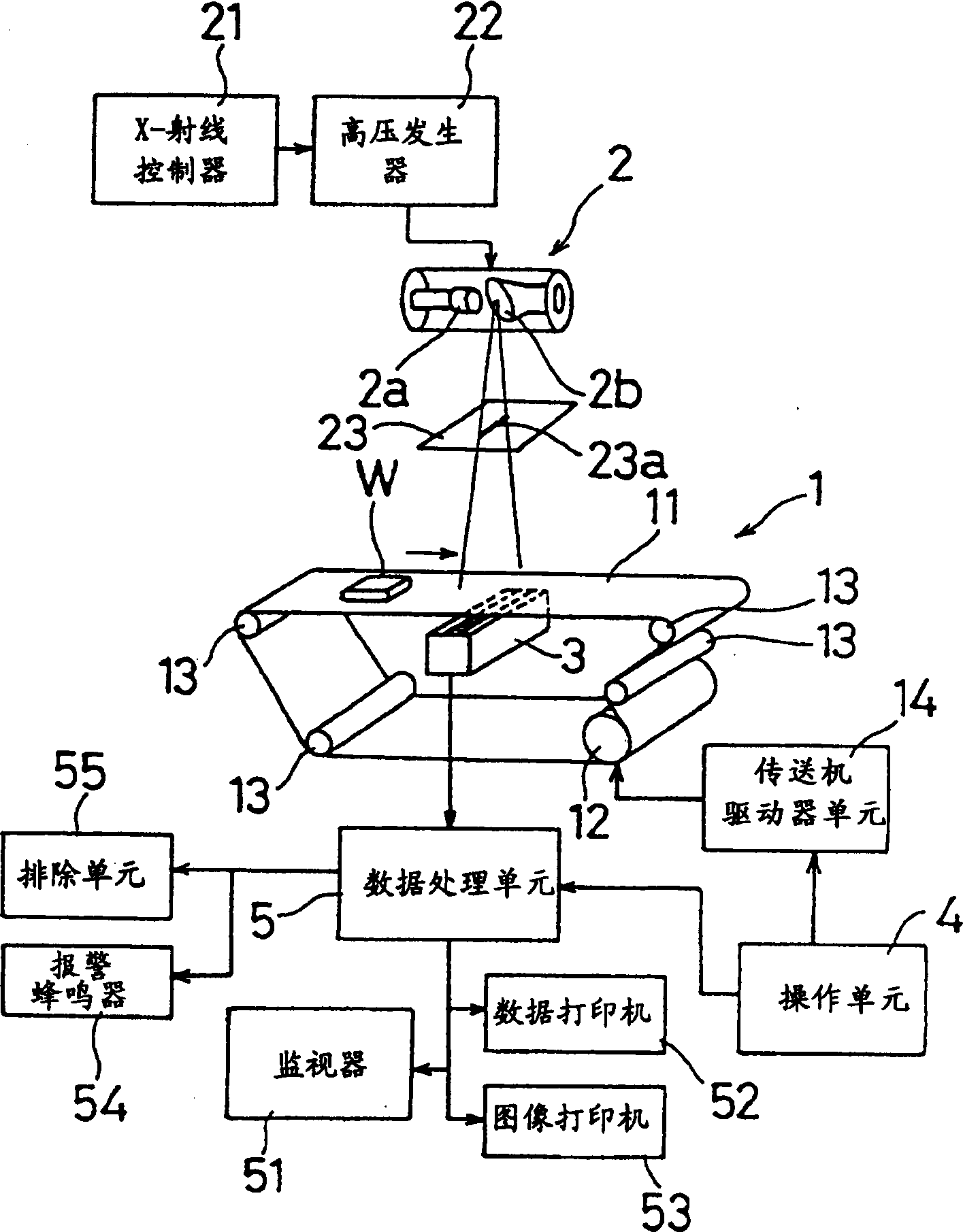

[0018] figure 1 It shows the composition of the radiation inspection apparatus according to an embodiment of the present invention and shows a schematic diagram of the mechanical structure of the main part of the embodiment and the system control circuit of the main part of the embodiment.

[0019] The inspected article W is placed on the endless belt 11 of the conveyor system 1 and conveyed at a fixed speed. Above the conveyor system 1, an X-ray tube 2 is arranged with its X-ray optical axis vertical and downward. In addition, the one-dimensional X-ray detector 3 is arranged vertically below the X-ray tube 2, and when the endless belt 11 of the conveyor system 1 is interposed between the X-ray tube 2 and the one-dimensional X-ray detector 3, a The three-dimensional X-ray detector 3 faces the X-ray tube 2 .

[0020] The conveyor system 1 comprises an endles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com