Stirling engines

A technology of Stirling engine and power cylinder, which is applied in the direction of Stirling engine, engine components, machine/engine, etc., can solve the problems of large volume and reduced freedom of machine layout, so as to improve theoretical efficiency and increase the scope of application. , the effect of increasing degrees of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention are described below with reference to the accompanying drawings.

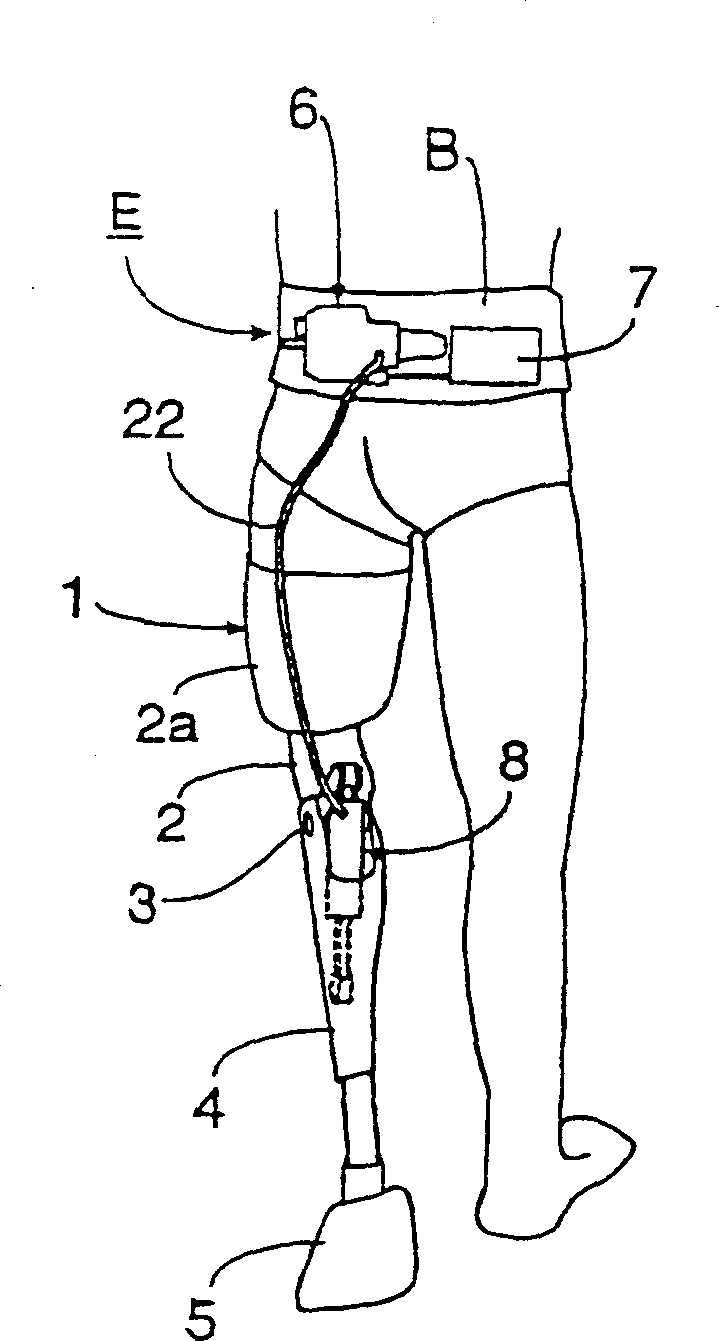

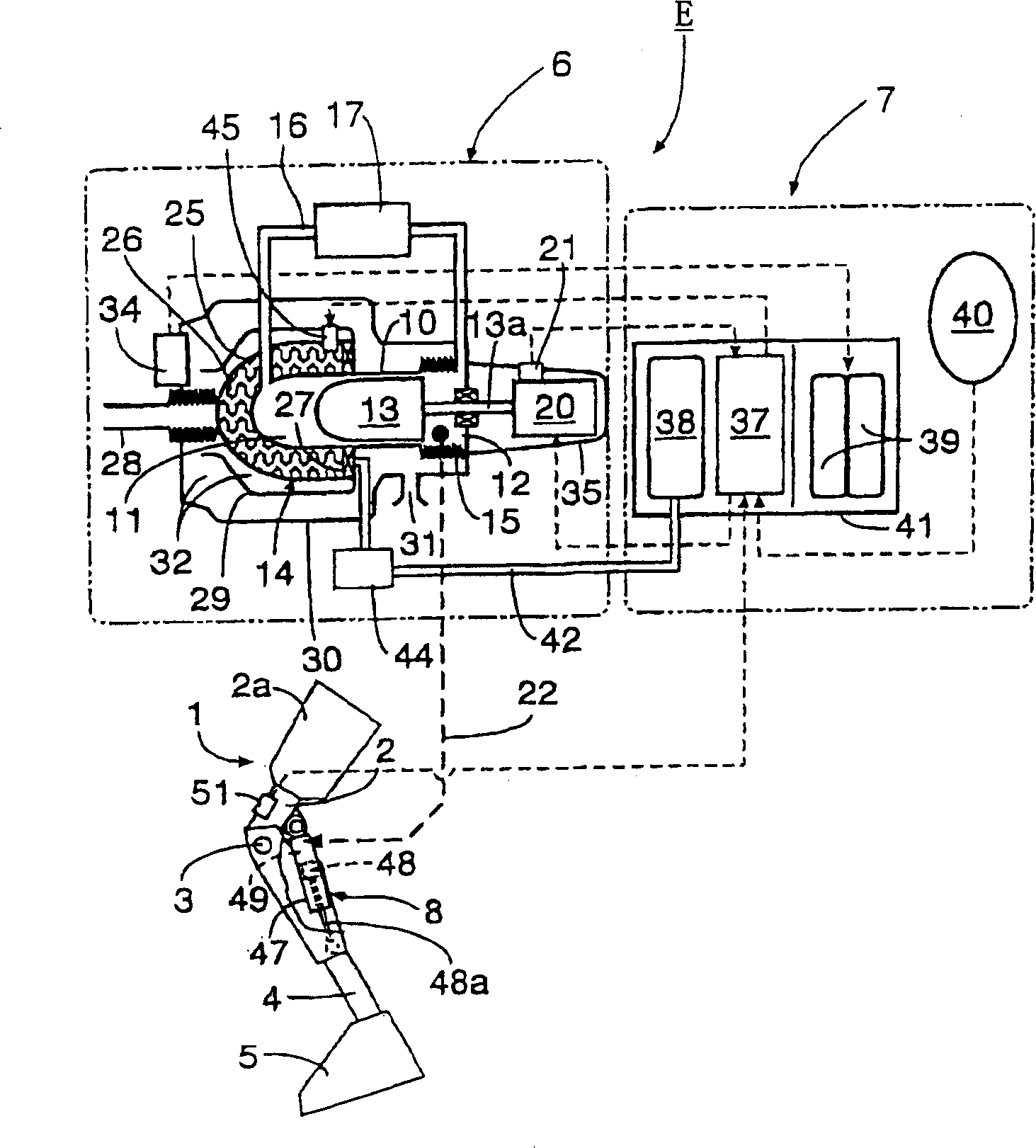

[0038] according to figure 1 and figure 2 A first embodiment of the invention is shown, figure 1 and figure 2 The Stirling engine E of the present invention is illustrated. Usually used to drive prosthetic legs 1 . The prosthetic leg 1 comprises a prosthesis 2 integral with a socket 2a; the socket 2a is for insertion of the residual leg by the patient. The artificial tibia 4 is flexibly / extendably connected to the lower end of the artificial thigh 2 through the artificial joint, and the foot 5 is connected to the lower end of the artificial tibia 4 .

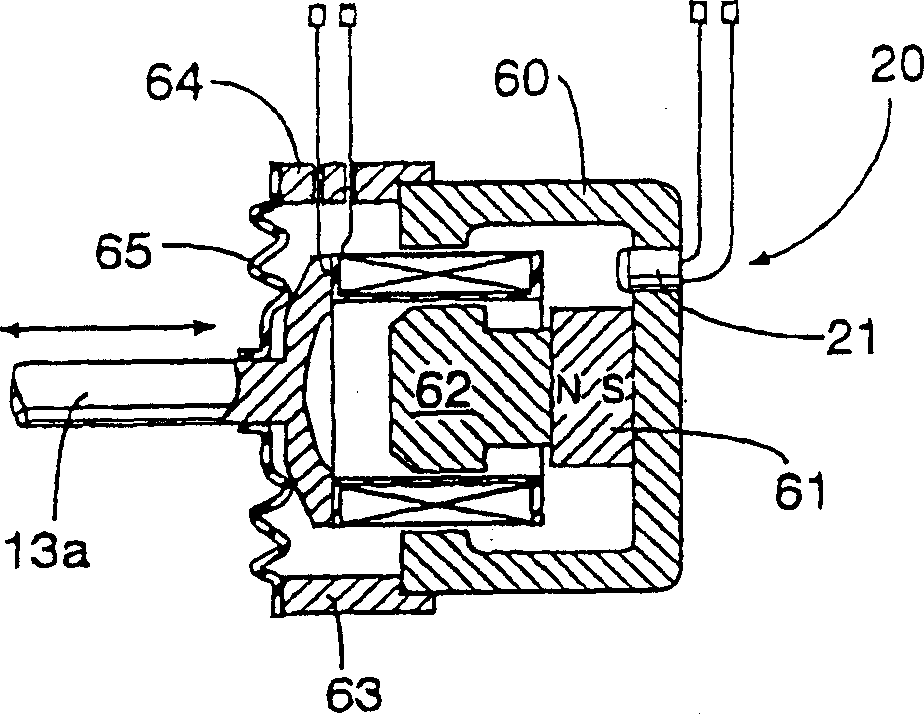

[0039] The Stirling engine E comprises a purge unit 6 and a control unit 7 . These two parts are mounted on the belt B, which is worn on the waist of the patient. The power cylinder 8 is installed on the prosthetic leg 1 and is located between the prosthetic thigh 2 and the prosthetic shin 4 . The pressure lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com