Differential pressure flowmeter with integrated pressure taps

A pressure difference and pressure hole technology, used in the process measurement and control industry, which can solve problems such as a lot of on-site installation time, large disassembly/reinstallation time, leakage at joints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

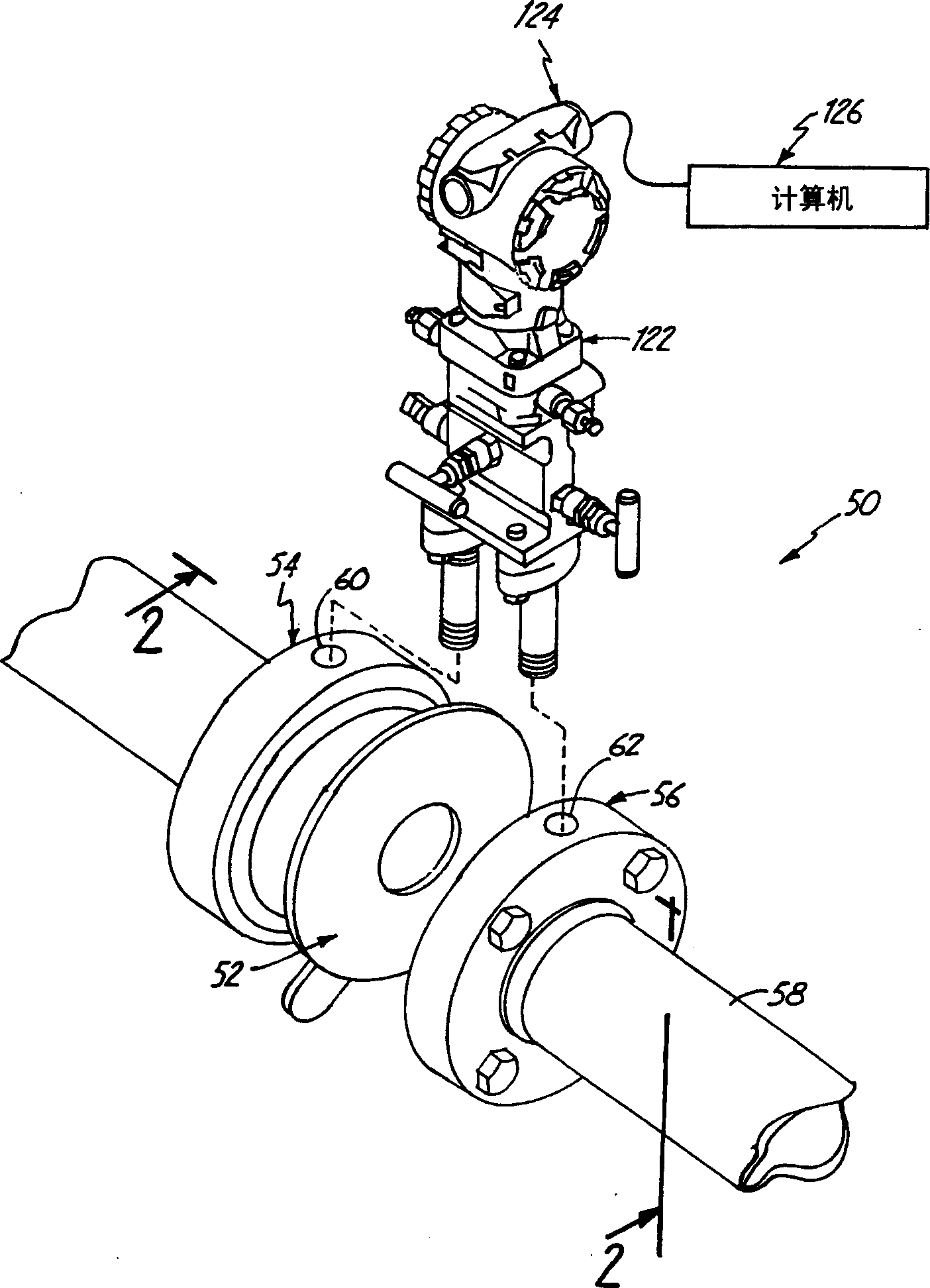

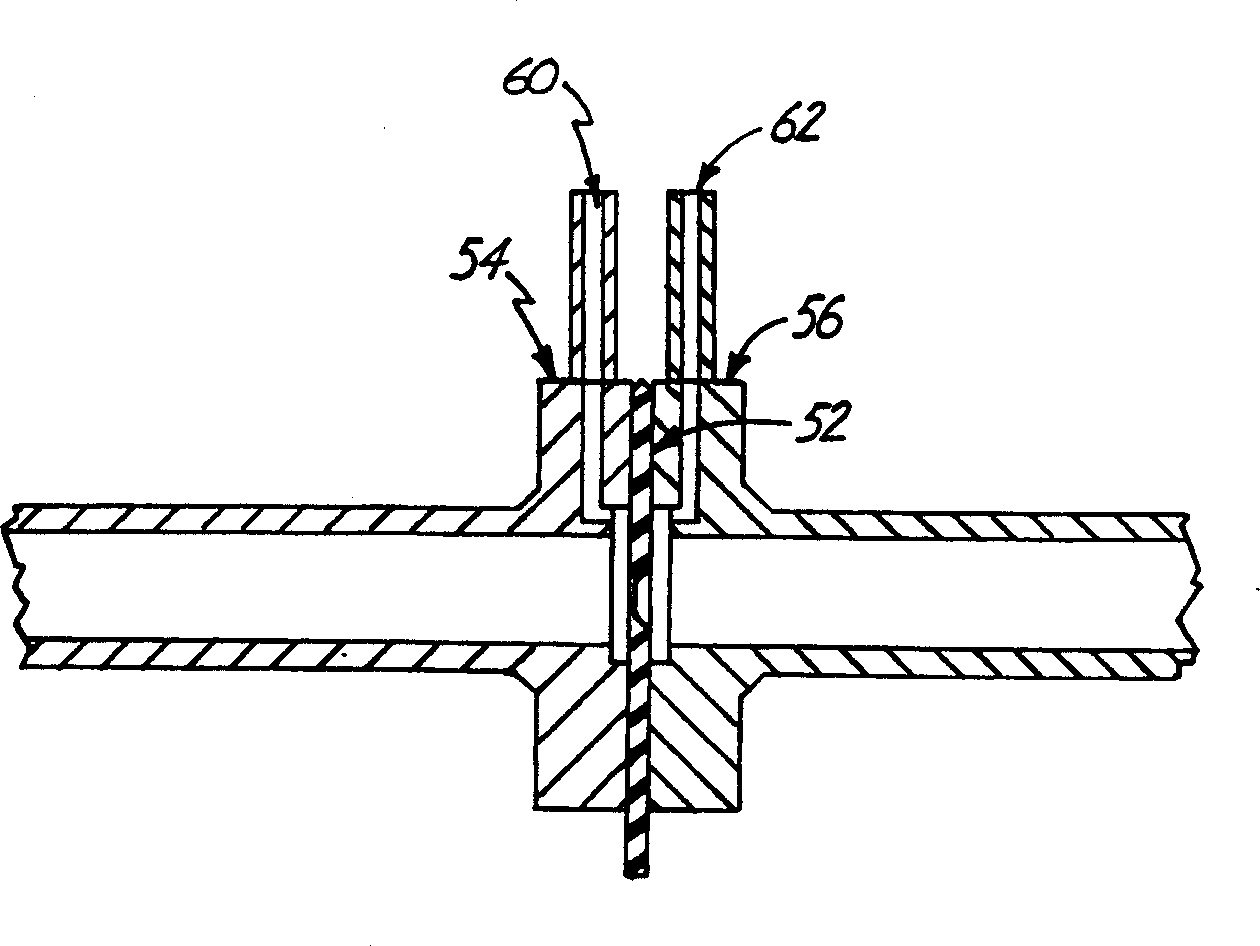

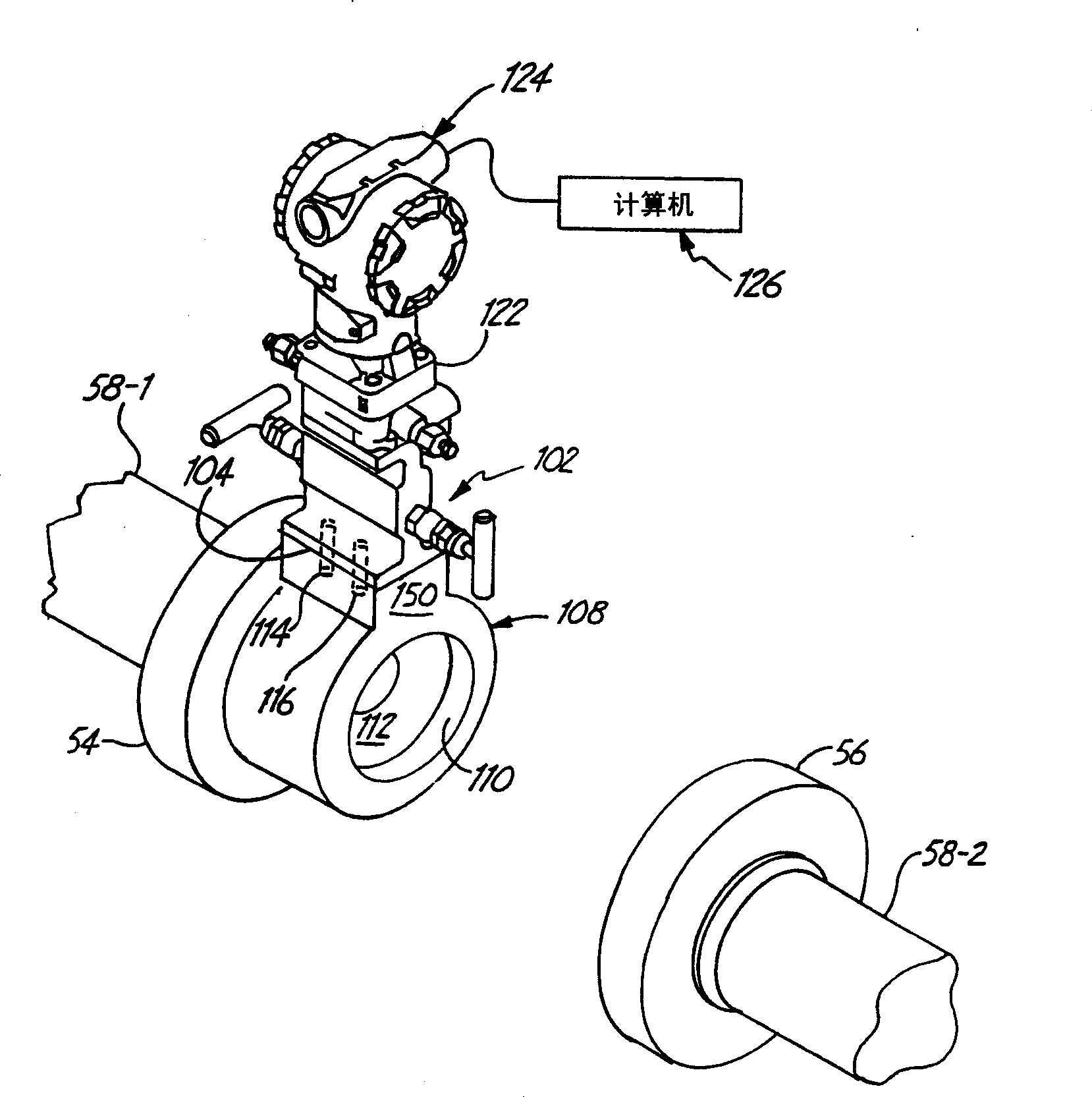

[0018] Figure 3-4 is an environmental depiction of one embodiment of a process flow device 100 of the present invention, including an instrument base 102 , first and second pressure orifice channels 104 , 106 and a differential flow plate 108 . The differential flow plate 108 includes a fluid conduit 110 supporting a fluid barrier 112 and first and second pressure holes 114, 116 (in Figure 4 briefly shown in ).

[0019] Such as Figure 4 As briefly shown, the instrument base 102 supports a processing instrument 120 . exist Figure 3-5 and 7, the processing instrument 120 includes a pressure sensor module 122 for isolating the differential pressure and a transmitter 124 for transmitting the processed data to a computer or readout device 126 (such as image 3 shown). A transmitter 124 or any other suitable readout device is capable of sensing process parameters and outputting the relevant output through the process loop to a control room or computer 126 so that the proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com