Developing liquid mfg. device and method

A technology for manufacturing devices and developing solutions, which is applied in semiconductor/solid-state device manufacturing, photography, transportation and packaging, etc., and can solve problems such as deterioration of developing solutions, large occupation, and concentration changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Preferred Mode of Carrying Out the Invention

[0051] Next, embodiments of the present invention will be described in detail. In addition, the same reference numerals are attached to the same elements, and overlapping explanations are omitted. And, the positional relationship is based on the positional relationship shown in the drawings unless otherwise specified. Also, the dimensional ratios in the drawings are not limited to the illustrated ones.

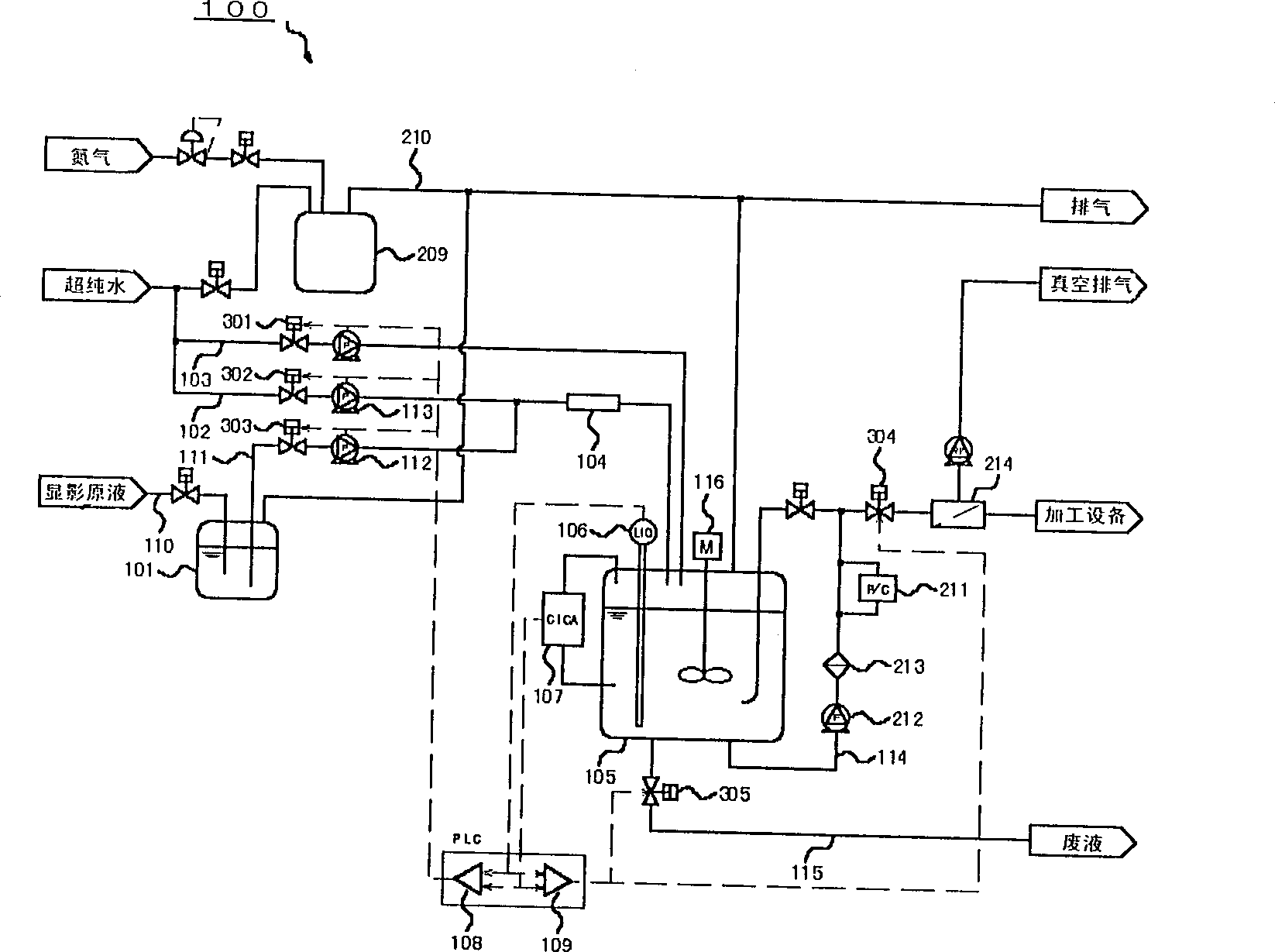

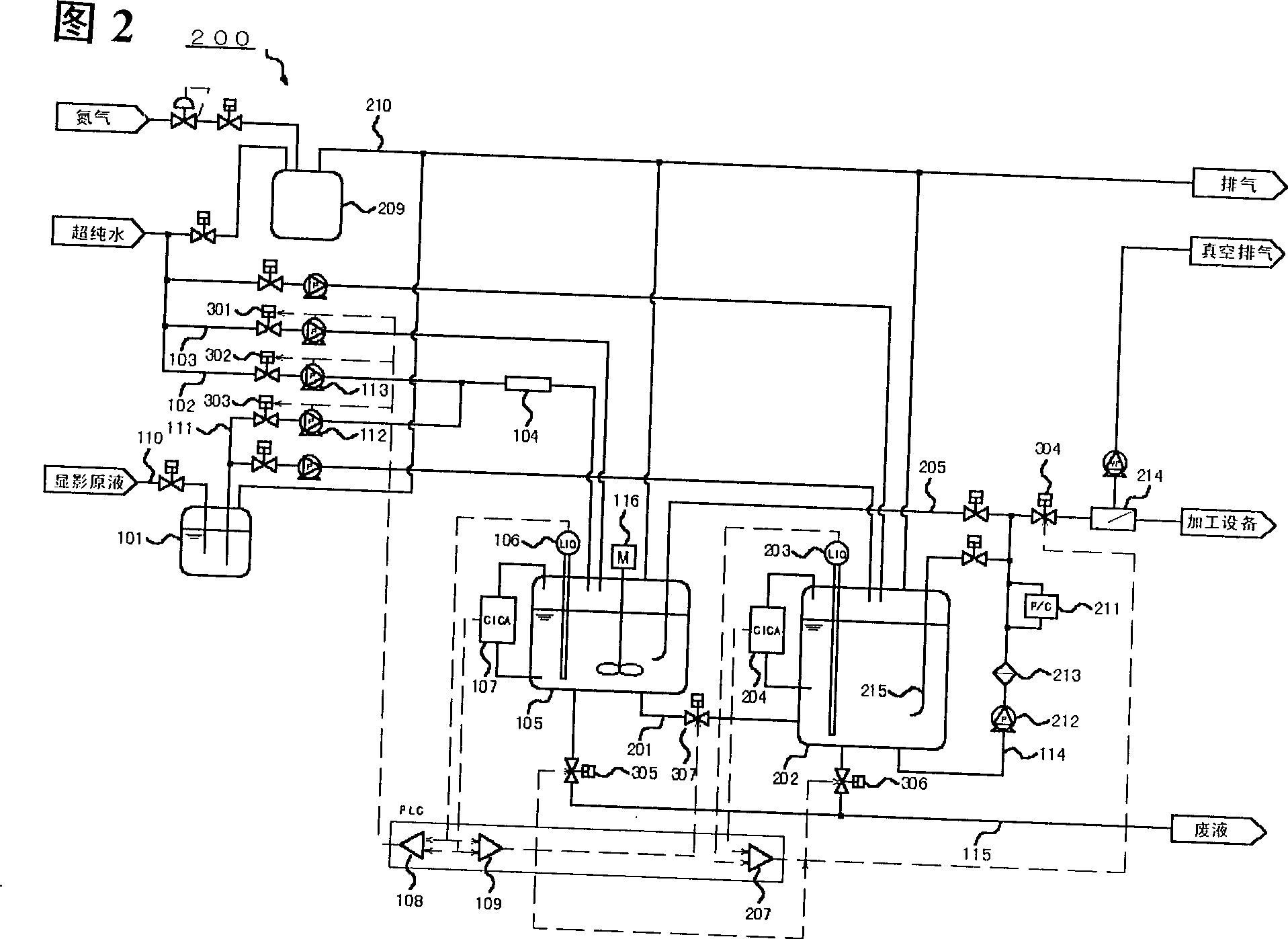

[0052] As mentioned above, figure 1 It is a system diagram schematically showing the structure of the first embodiment of the developer solution manufacturing apparatus of the present invention.

[0053] The developer solution manufacturing apparatus 100 includes a developer solution tank 101 storing a developer solution, and a preparation tank 105 connected to a pure water supply system. The original developing solution is stored in the original developing solution tank 101, and the original developing solution is repl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com