Fixed barrier module

A technology of barriers and castings, applied to building components, walls, buildings, etc., can solve problems such as interrupting business operations, moving at will, and not being able to move easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

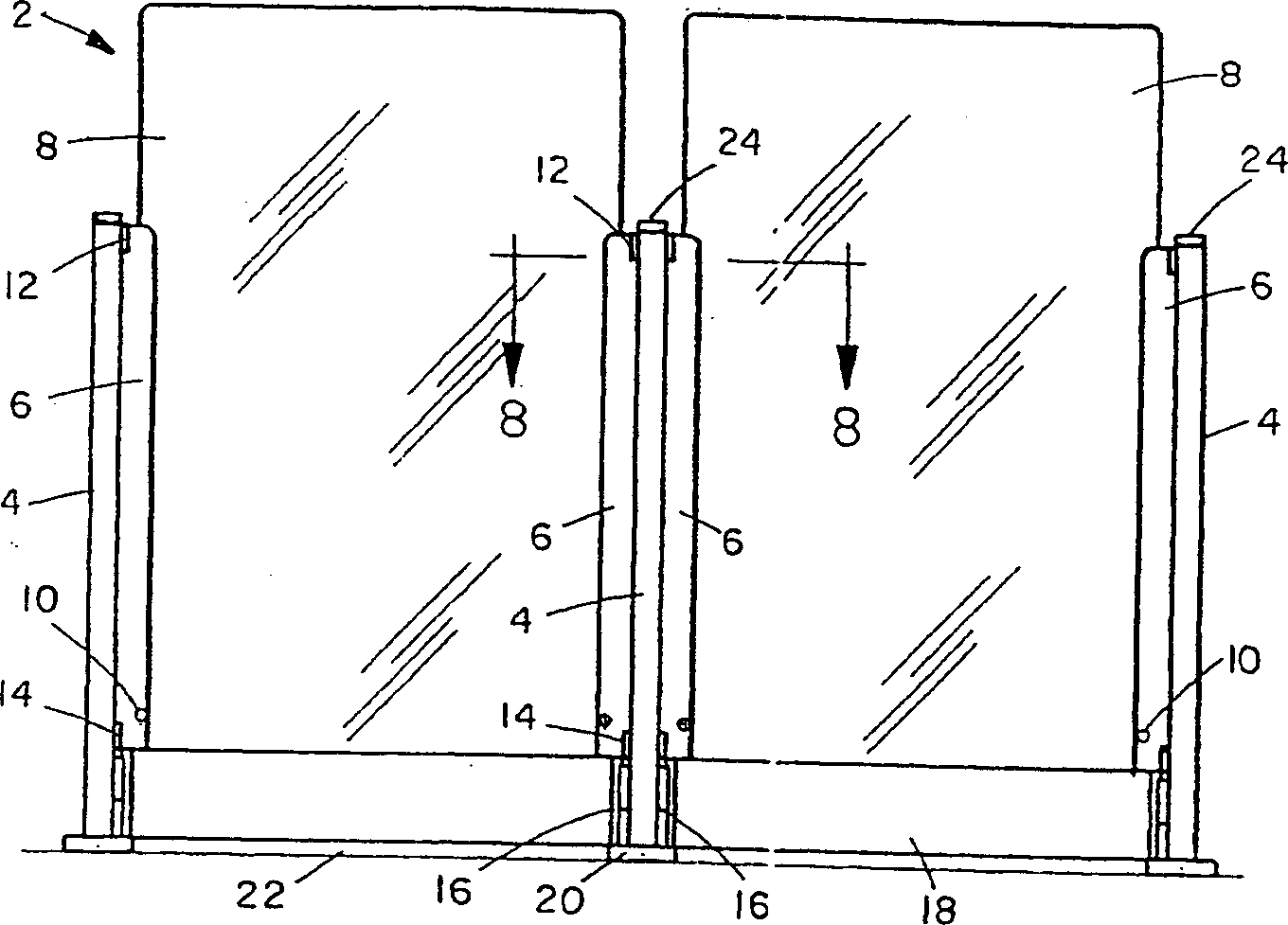

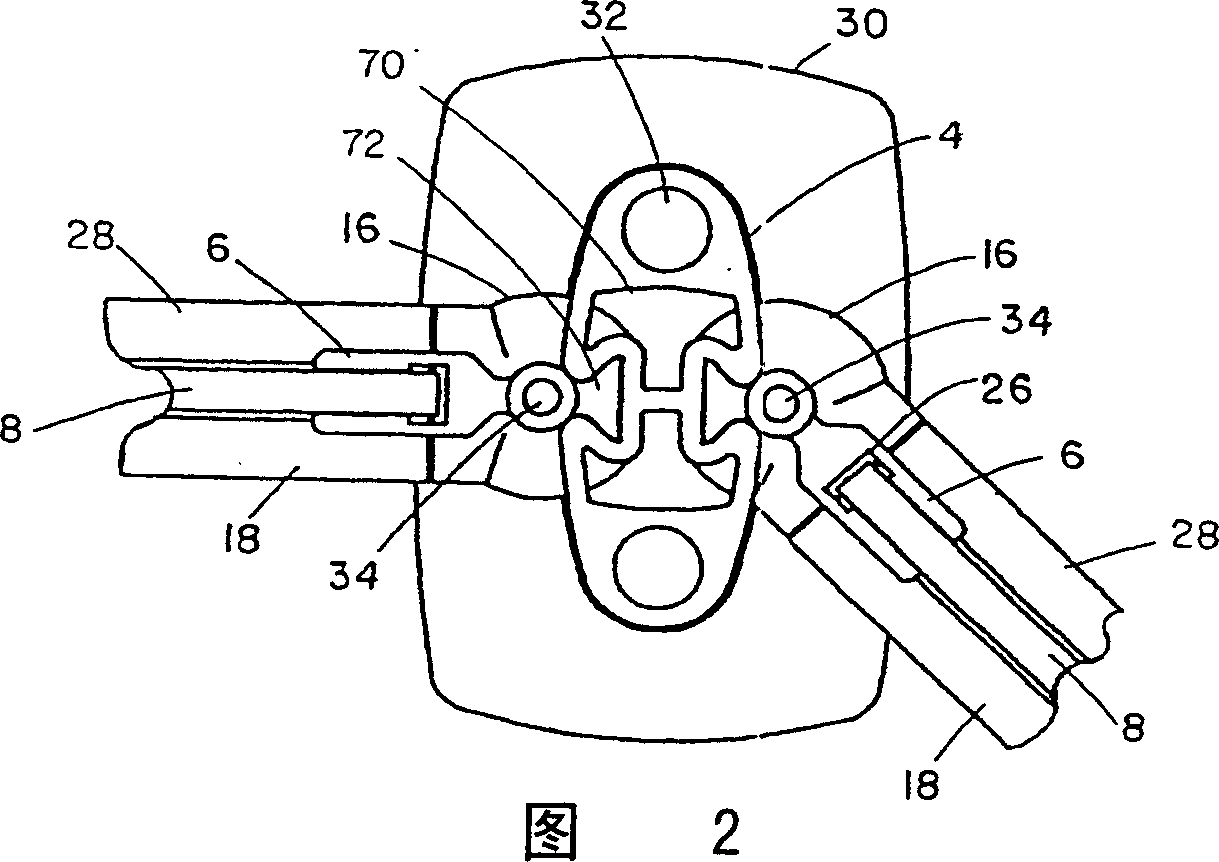

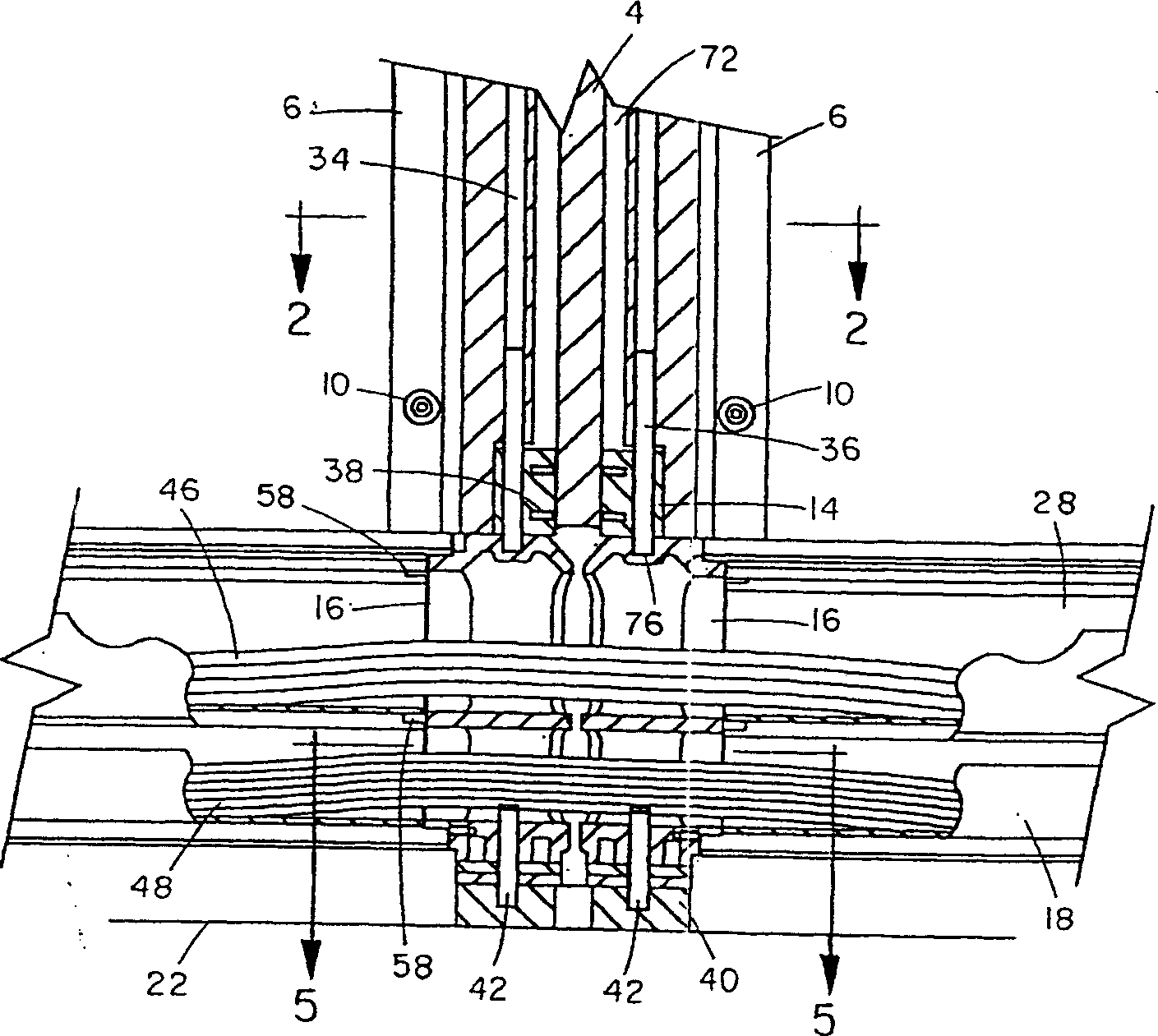

[0029] figure 1 Two component parts of a fixed barrier 2 in a preferred embodiment are shown. Each module part comprises a panel part 8 which is supported by a main post 4 on either side of the panel part 8 . In a preferred embodiment, the panel portion 8 is constructed of a clear material such as glass or plexiglass. Another embodiment of the present invention employs an opaque panel portion 8 made of other materials such as metal, wood, fabric and plastic or combinations thereof. The panel section 8 is held in place by the glass bracket extrusion 6 which is hingeably connected to the main column 4 at an upper hinge pin support 12 and a middle hinge pin support 14 . Each panel section 6 may be positioned 690 degrees from an adjacent panel section. Security screws 10 are provided to prevent the panel part 8 from being released from the glass carrier extrusion 6 . Image 6 A side view of the security screw 10 passing through the panel 8 and the glass support extrusion 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com