Clutch assembly

A clutch and assembly technology, applied in clutches, friction clutches, fluid-driven clutches, etc., can solve the problems of complex and expensive clutch assemblies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

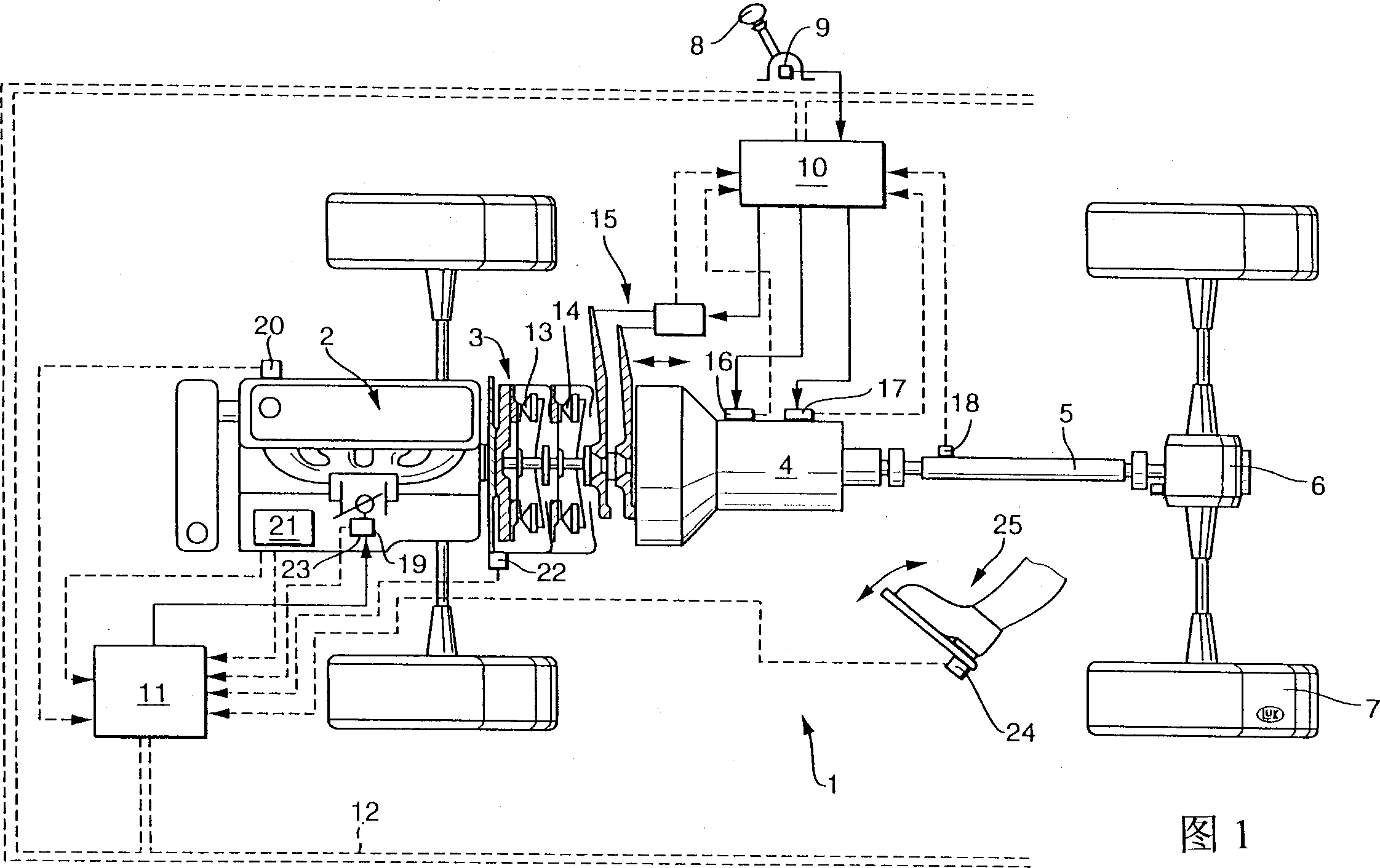

[0023] Figure 1 shows a car 1 with a transmission line, which includes an engine 2, a clutch assembly 3 and a gearbox 4 composed of an internal combustion engine. The wheels 7 of the automobile 1 are driven via a transmission shaft 5 and a differential 6. In its meaning, it can of course also be a car with one or more other driven axles.

[0024] Also shown here is a shift selection device 8 with a sensor 9 such as a shift lever, and a control device 10, 11 in the form of a block diagram. The control devices 10, 11 may be constructed as a unit, or may be designed in a local area separated in structure and / or function. If the control devices 10 and 11 are designed in local areas separated in structure and / or function, they can be connected to each other via a CAN bus 12 or other electrical connection methods for data exchange, for example. The control devices 10 and 11 are used, for example, to control the automatic operation of the gearbox 4 and / or to control the clutches 13, 14 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com