Self-aligning interface apparatus for use in testing electrical devices

A technology for automatic alignment and interface devices, applied in the direction of electronic circuit testing, measuring devices, measuring device casings, etc., can solve problems such as limited equipment achievements, tedious procedures, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

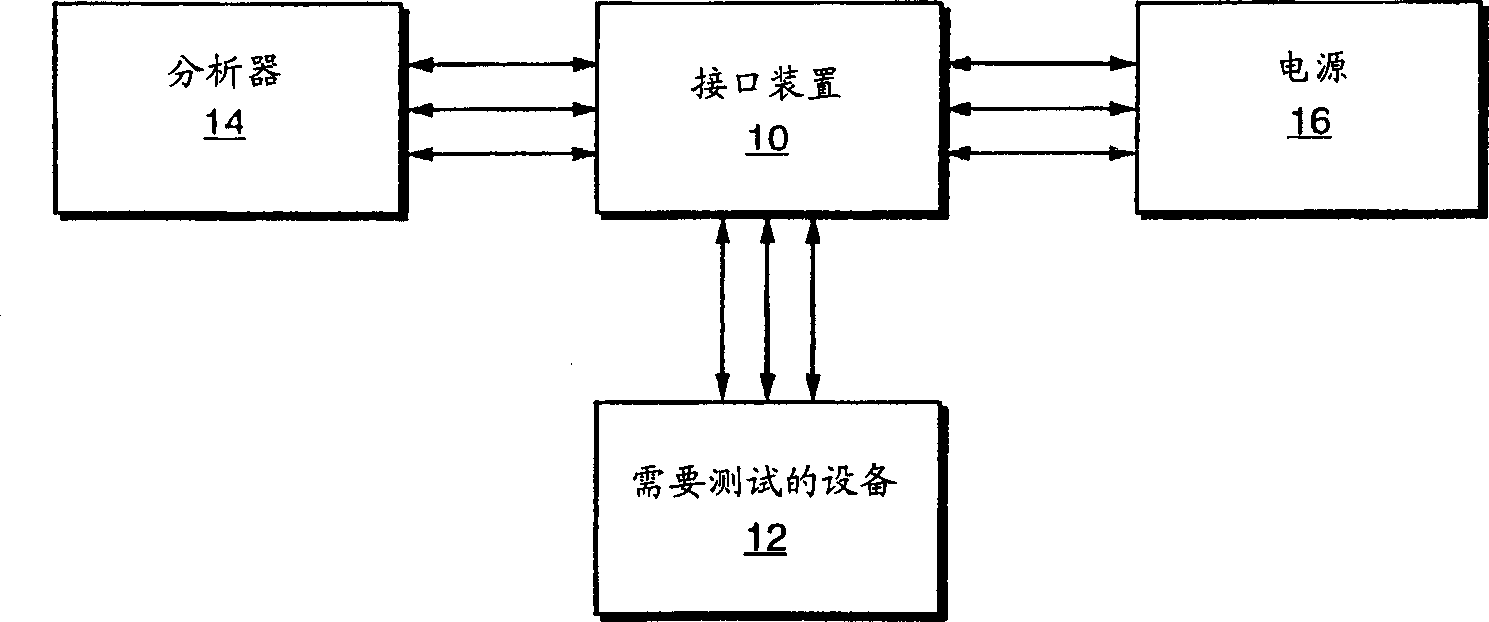

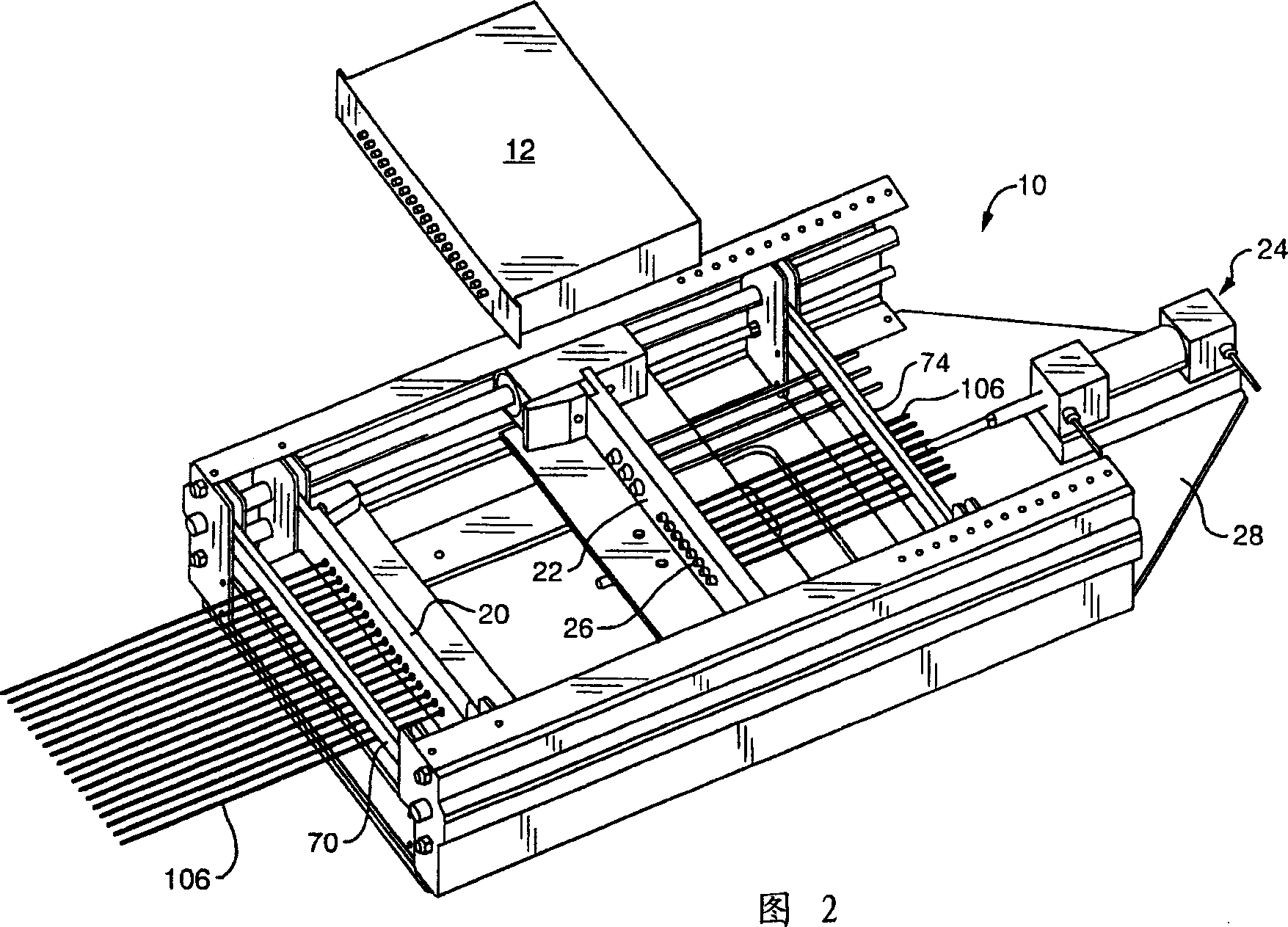

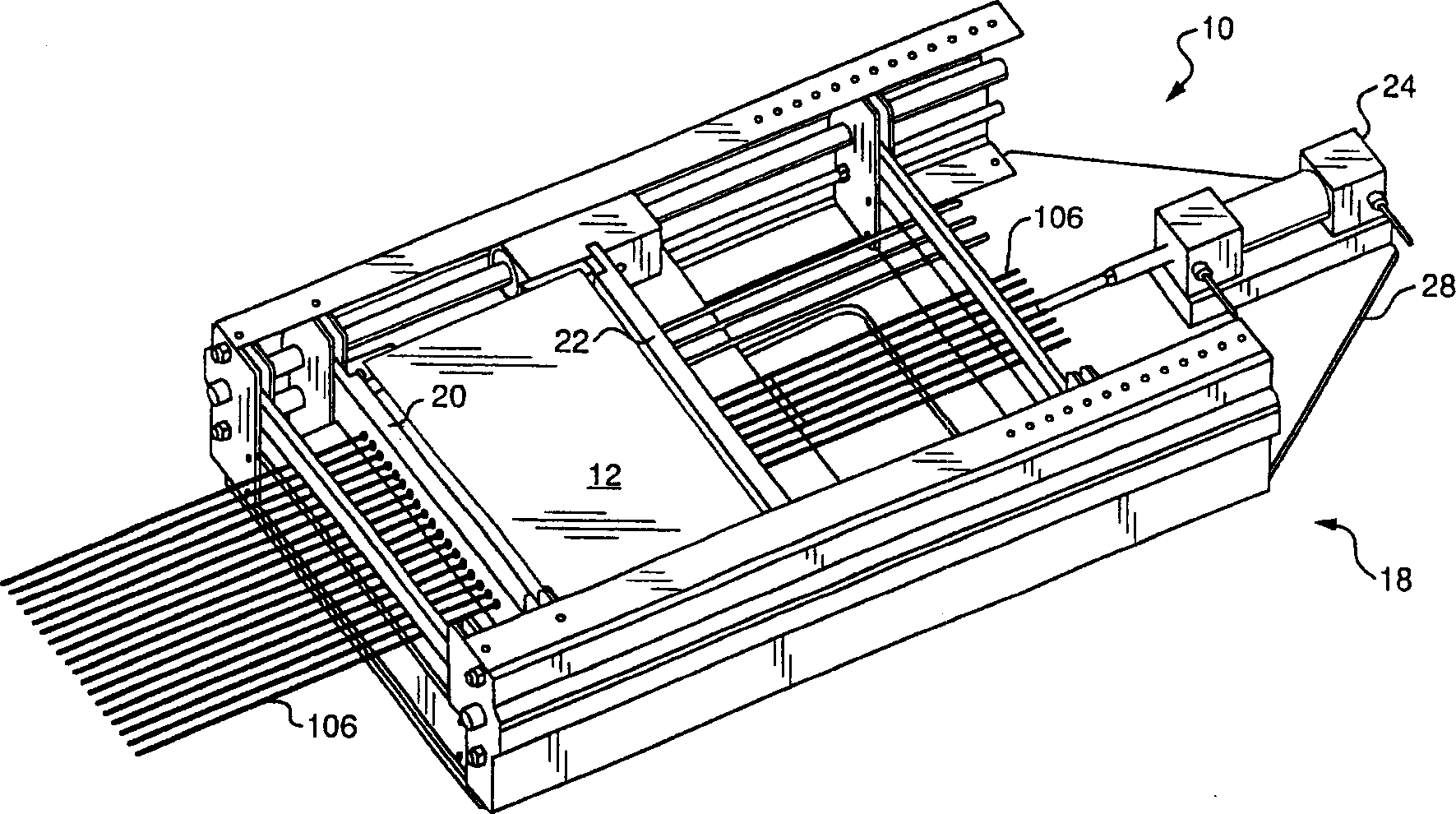

[0019] Refer now to the attached drawings, especially figure 1 To FIG. 5, the interface device 10 involved in the present invention is shown. The interface device 10 can interconnect a device 12 that needs to be tested with an analyzer 14 and a power supply 16 for testing the device that needs to be tested. Together. As will be described in detail below, the interface device 10 includes a fixing device 18, a pair of interface elements 20 and 22, and a pushing assembly 24. The interface elements 20 and 22 are equipped with a plurality of auto-aligning coaxial connectors 26, and the positions of these auto-aligning coaxial connectors are basically aligned with the matching connectors 27 on the device 12. The interface device 10 shown in FIG. 2 is in its open position to receive the device 12. image 3 The interface device 10 shown in is in the closed position and the connector 27 is connected to the auto-aligned coaxial connector 26. The pushing assembly 24 is installed on the base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com