Electric machine

A technology of rotors and force-applying components, which is applied in the field of motors and can solve problems such as poor position accuracy and deterioration of rotary position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

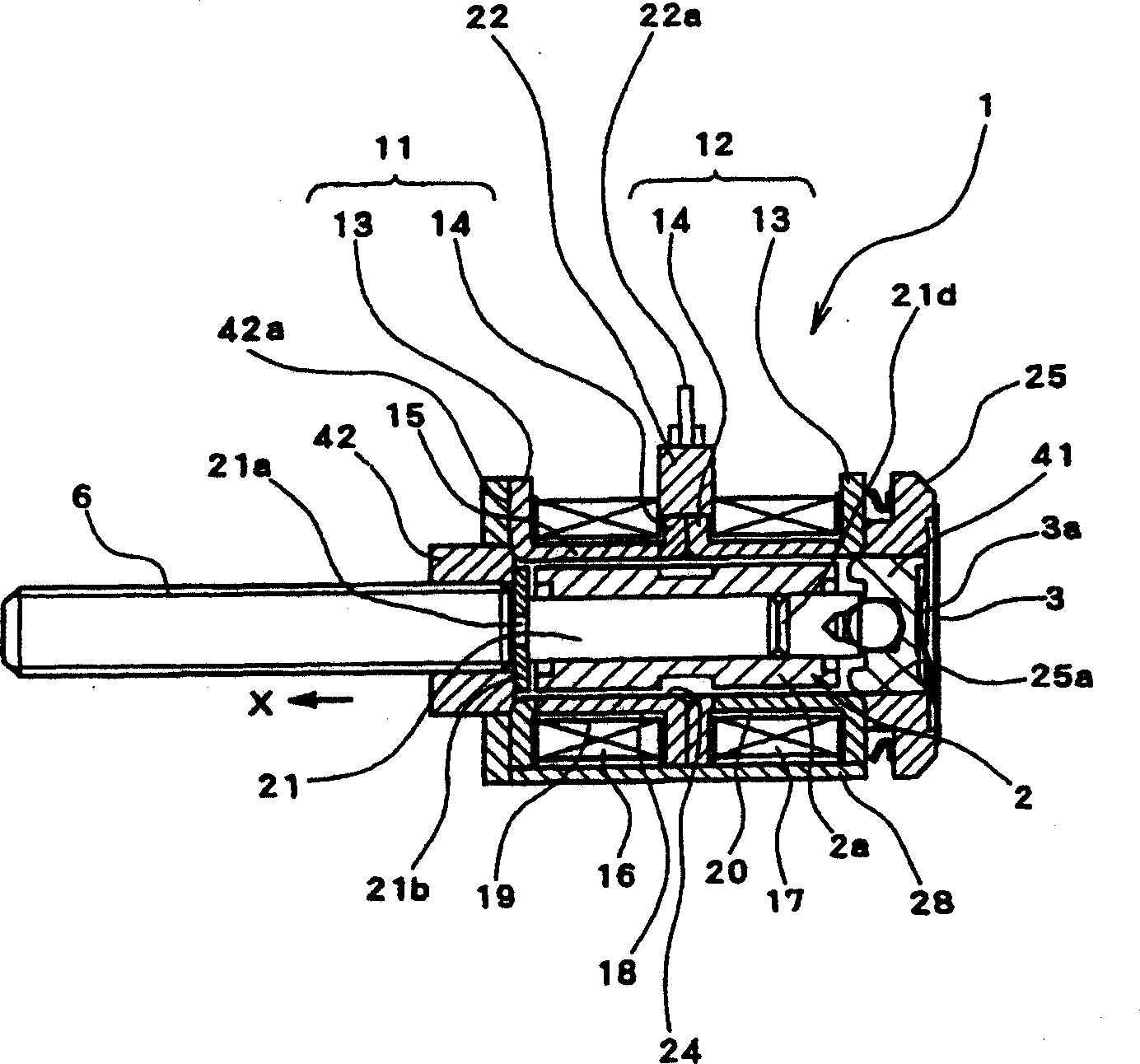

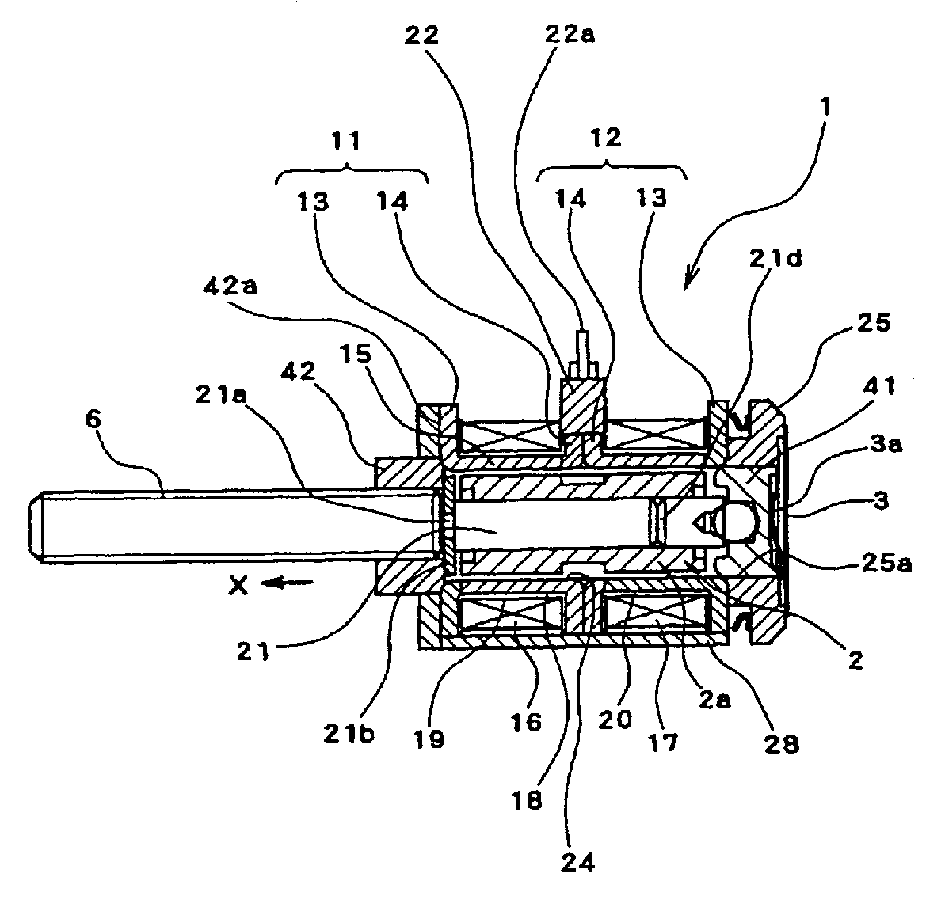

[0014] Embodiments of the present invention will be described below. figure 1 It is a sectional view showing the overall structure of the motor according to the embodiment of the present invention.

[0015] Such as figure 1 As shown, the motor of the embodiment of the present invention (this embodiment adopts the structure of a stepping motor, referred to as a motor for short here) has a stator 1 and a rotor 2 arranged opposite to the stator 1 . The rotor 2 is in the axial direction generated by the force member 3 described later (more specifically, figure 1 In the arrow X direction) to turn under the state of force. In addition, one end of the rotation center shaft 4 of the rotor 2 protrudes through a bearing 42 formed integrally with the stator 1 , and a threaded shaft portion 6 is formed at the penetrating portion and the protruding portion.

[0016] The stator 1 has a structure in which two sets of metal stator cores 11 and 12 are axially overlapped, and a rotatable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com