Core of elastic creeper tread

A technology of elastic body and body shoe, which is applied in the field of core bone, can solve the problems of accelerating the fatigue crack of rubber elastic body, restricting the degree of freedom of deformation, elastic strain concentration, etc., and achieve the effect of improving rigidity, improving bonding strength and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

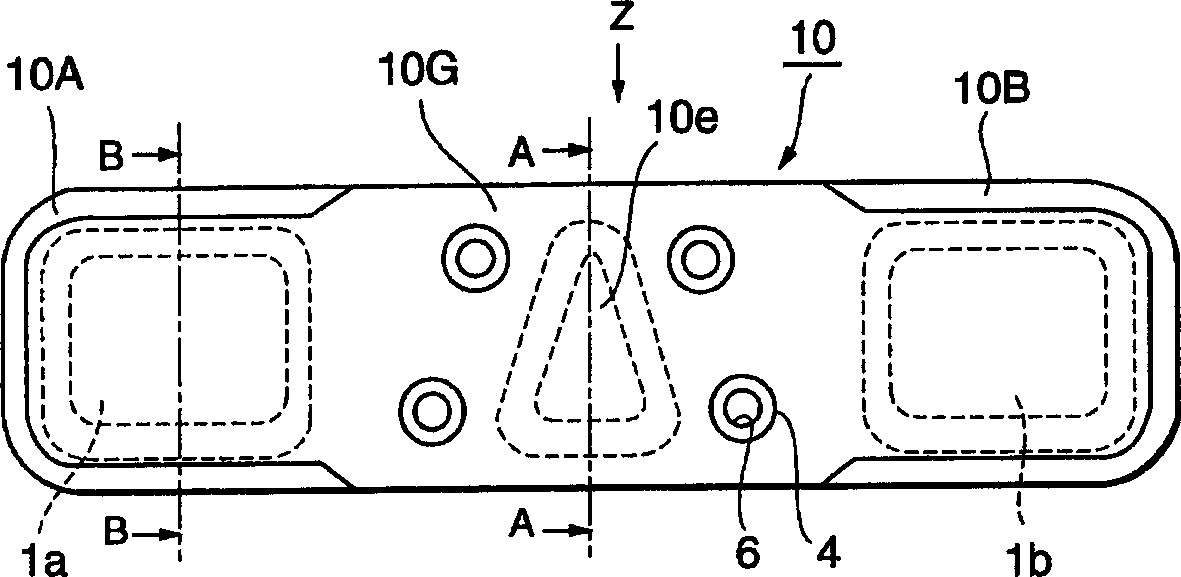

[0039] A preferred embodiment of the core bone of the elastic body track shoe of the present invention will be described in detail with reference to the accompanying drawings.

[0040] First, through figure 1 and figure 2 An elastomer track shoe in which the core bone of the present invention is embedded will be briefly described.

[0041] The elastic track shoe used in the endless rubber track of construction machines such as hydraulic excavators has an elastic body 2 made of rubber or the like, and core bones 1 and 10 embedded in the elastic body 2 . The central parts 1G and 10G of the metal cores 1 and 10 are exposed on the non-contact surface side, and the exposed surfaces and the non-contact surface of the elastic body 2 form flush surfaces at the ends in the front-rear direction. In addition, the detailed structure is as described in each of the following embodiments. The core bone 1, 10 embedded in the elastic body 2 forms a substantially flat surface inside and out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com