Method and apparatu sfor recovering fibres from white water of paper mill

A technology for recycling fiber and white water, which can be used in papermaking, papermaking machines, separation methods, etc., and can solve problems such as difficult implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

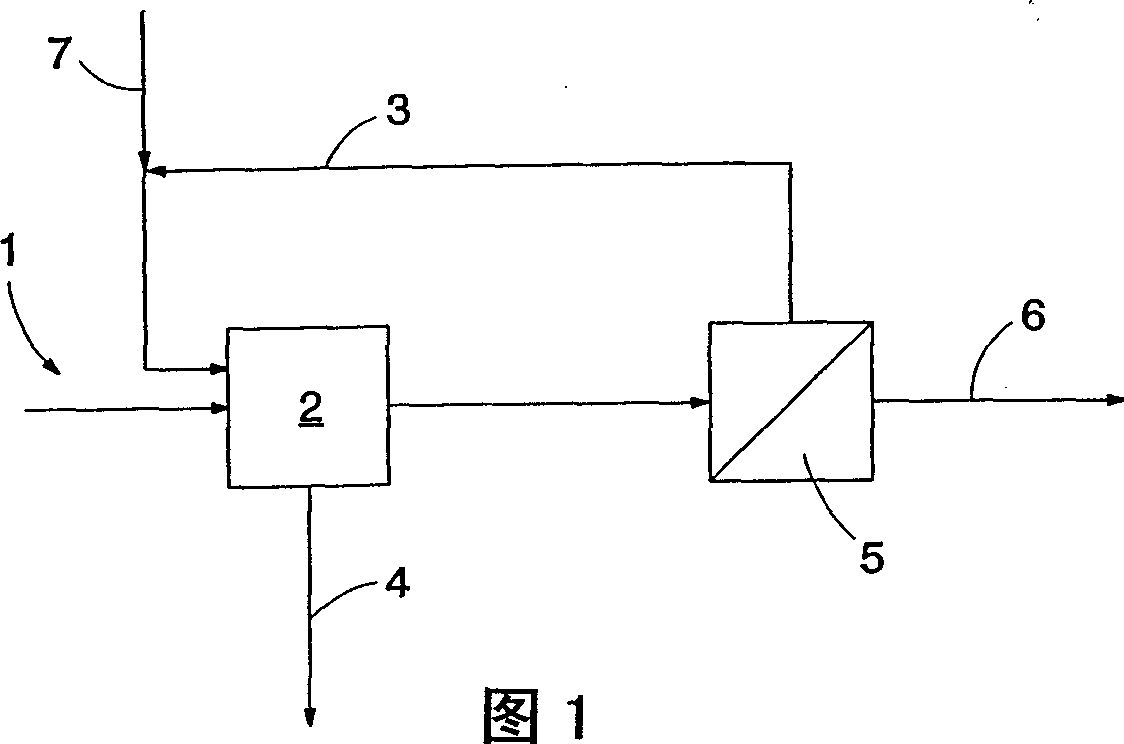

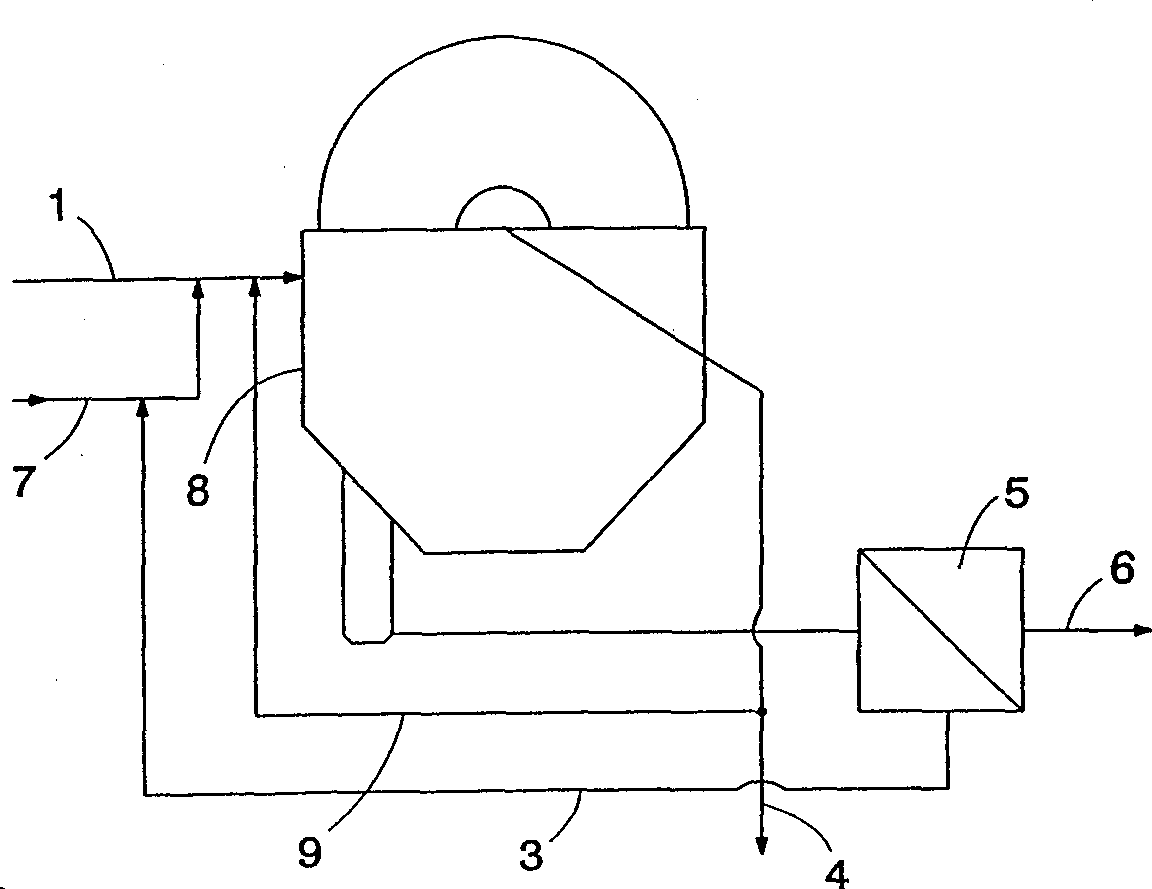

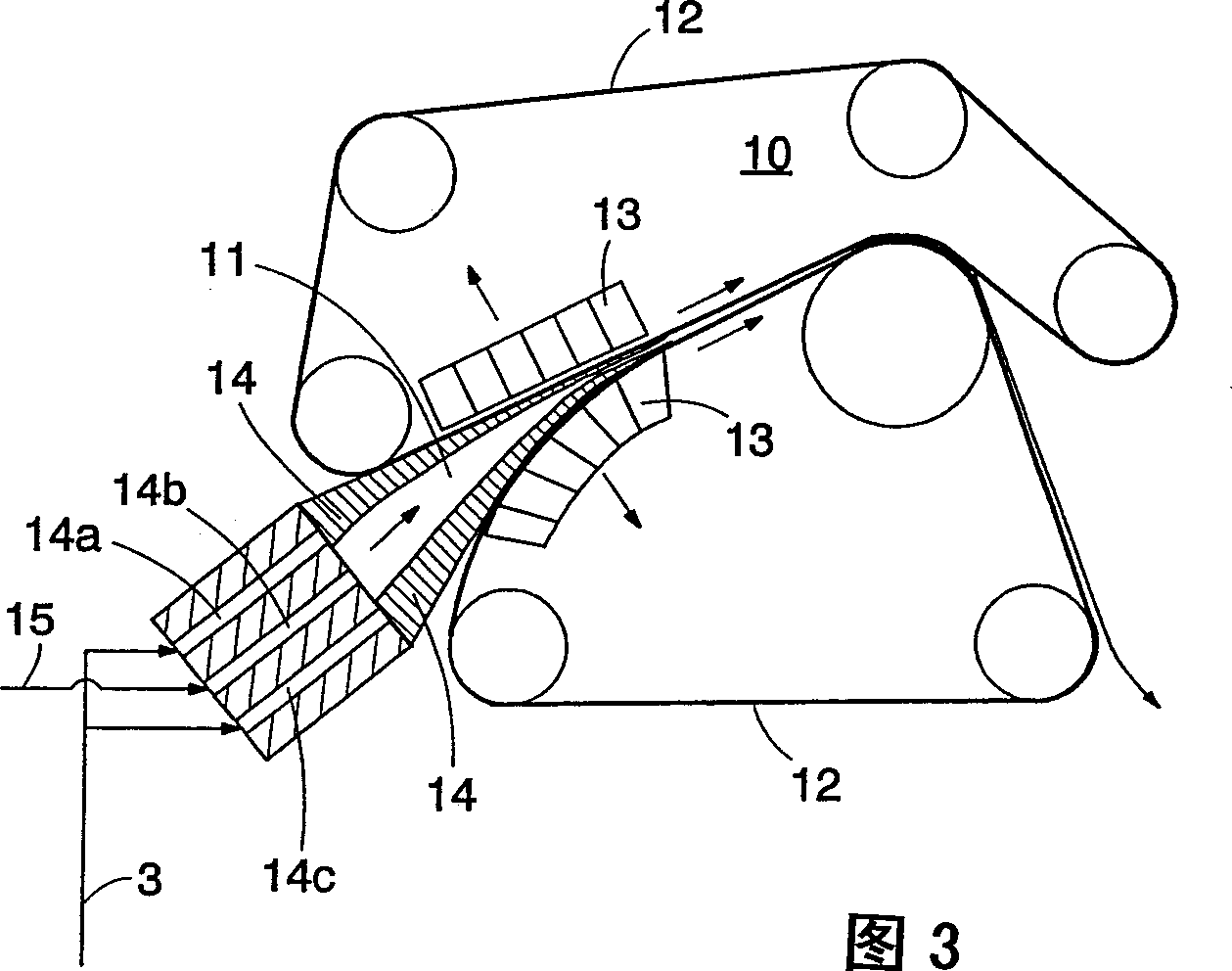

[0017] Figure 1 is a block schematic diagram representing an embodiment of the method for carrying out the invention. In this embodiment, the filter 2 is supplied with filtered water or filtrate via the input channel 1 . The secondary slurry forms a layer of material on the filter surface of the filter 2 which collects from the filtrate the fibers entrained therein. and is discharged in a conventional manner together with the short fiber fraction; the auxiliary stock is fed to the filter 2 through a bypass channel 3 . The water separated from the filter 2 is conveyed through an output channel 4 to a suitable place, for example, back to the paper making process, or to a waste water treatment plant. The slurry separated from the filtering surface of the filter 2 is sent to a sorting device 5 to be sorted into a short fiber fraction and a long fiber fraction. The staple fiber fraction is conveyed back to the papermaking process through the feed channel 6 . The long fibers are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com