Reusable printing plate

A printing plate and printing surface technology, which is applied in the preparation of printing surface, photoengraving process of pattern surface, printing and other directions, can solve problems such as expensive and time-consuming, achieve simple and reliable production, small preparation time, and realize hydrophobicization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

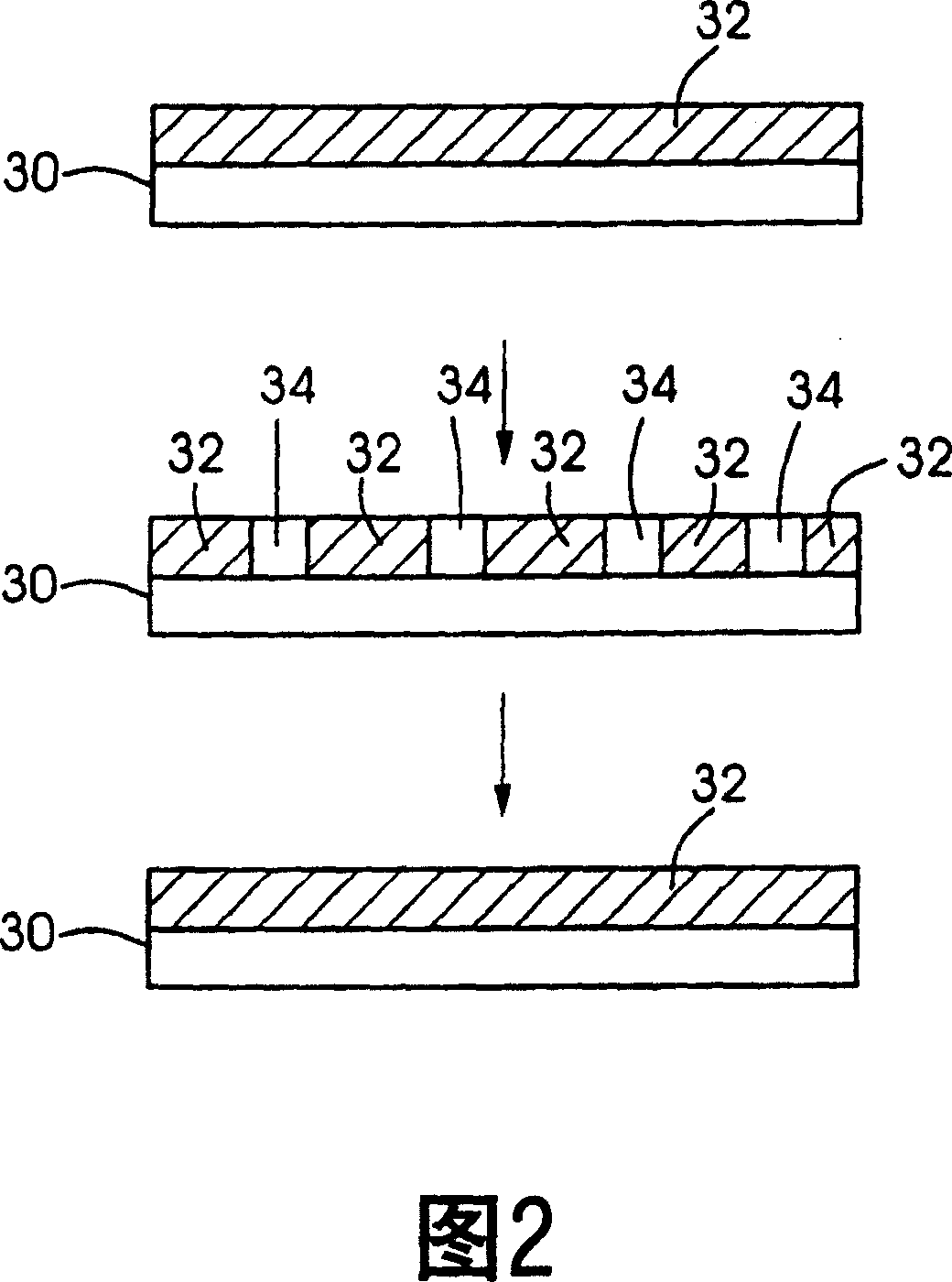

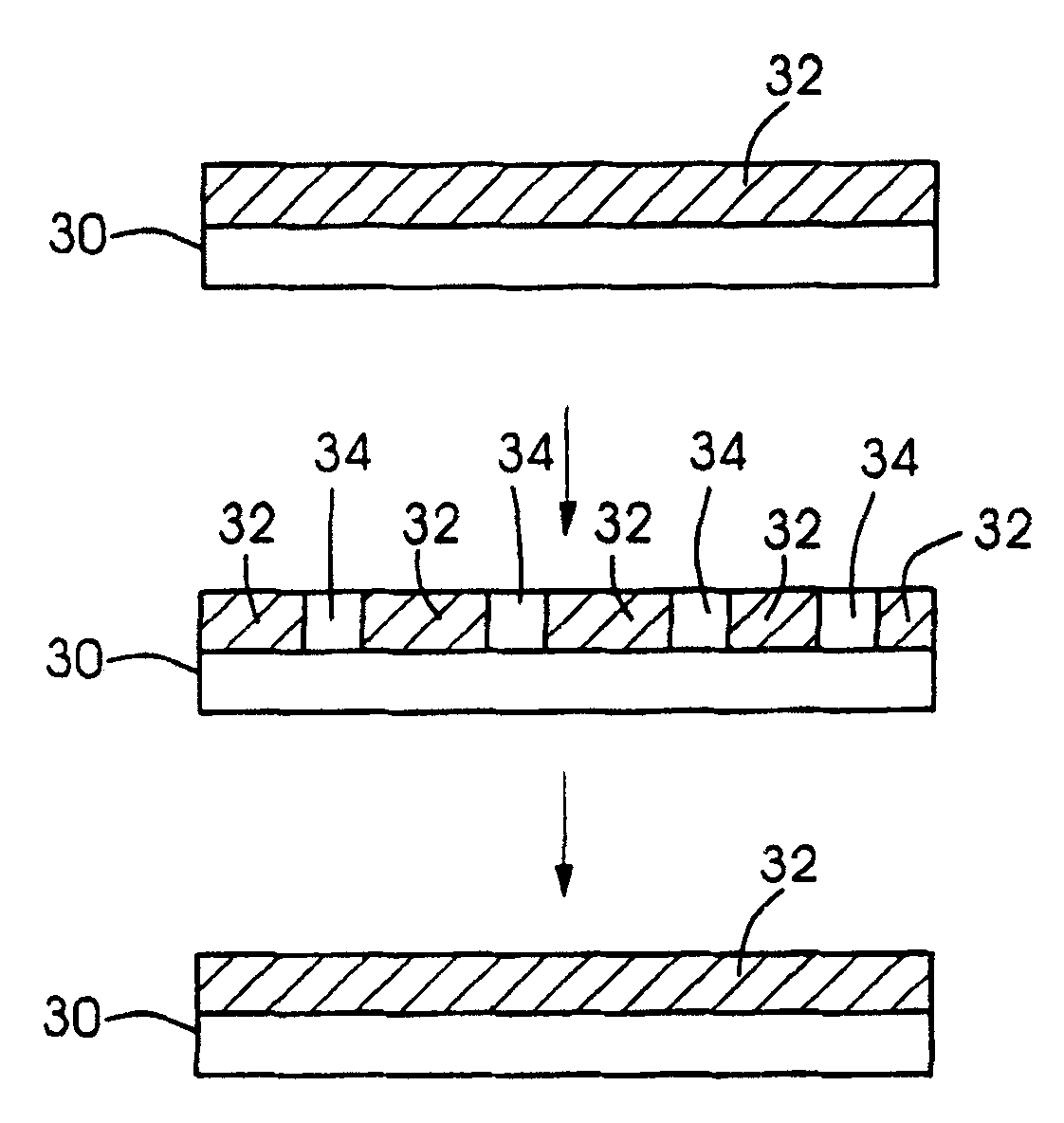

[0037] An advantageous embodiment of the reusable printing plate according to the invention and the pattern formation of the reusable printing plate according to the invention will be described below by means of the example of a naturally oxidized titanium surface and n-octadecane-phosphonic acid. An advantageous embodiment of the method, wherein the universality is not limited in terms of hydrophilic-lipophilic organic compounds and in terms of metal oxide surfaces.

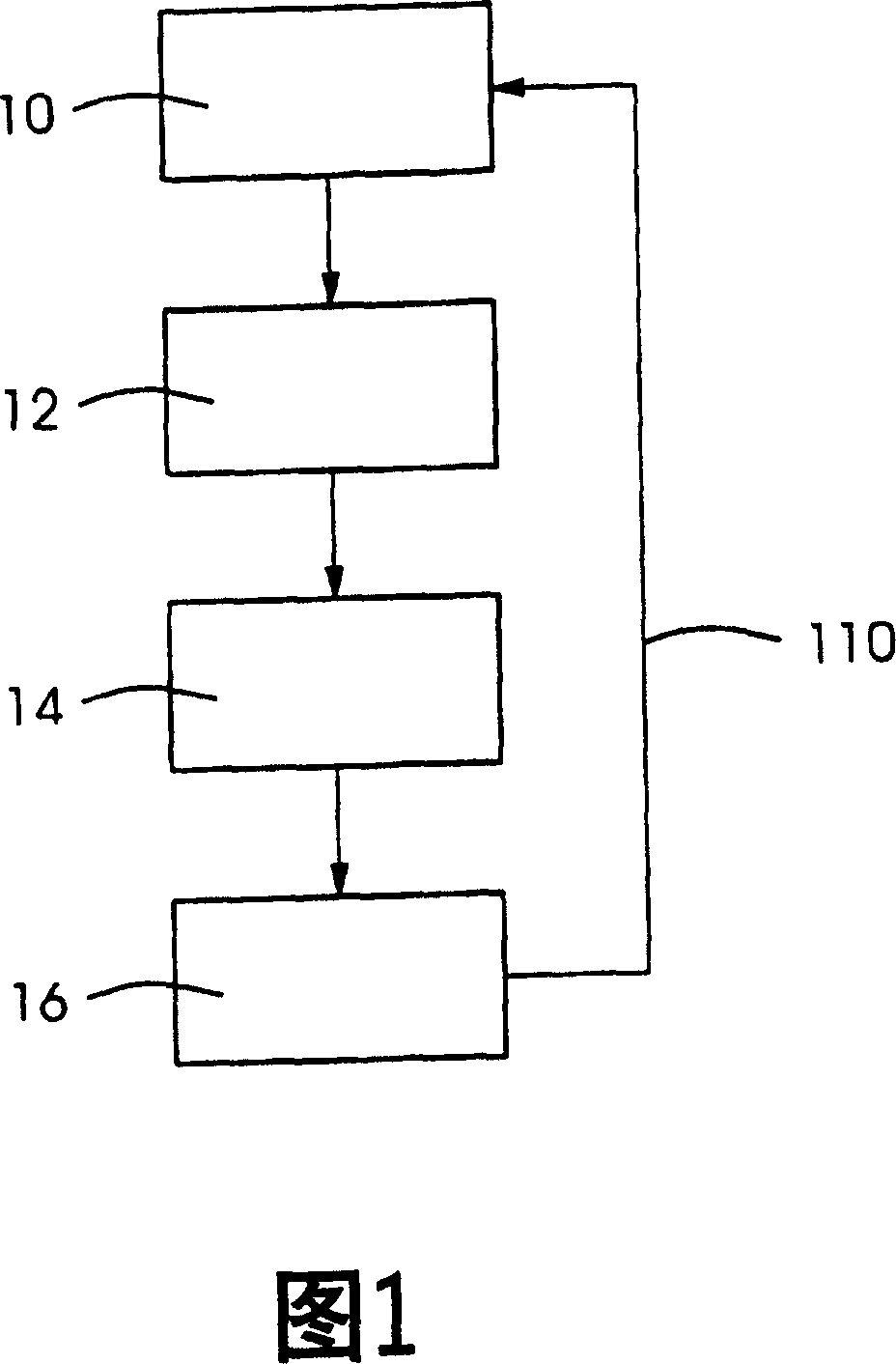

[0038] Figure 1 shows a flow chart of an advantageous embodiment of the method according to the invention for forming graphics of a reusable printing plate according to the invention. Samples with a titanium surface are available from the company "Goodfellow". In order to firstly decontaminate the titanium surface to be treated, it is irradiated with light in the ultraviolet wavelength range. Step 10 of the method of preparing a reusable printing plate comprises applying a hydrophilic-lipophilic organic compoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com