Badminton racket

A technology of badminton rackets and vertical rods, applied in the field of badminton rackets, which can solve problems such as reduced bonding strength, reduced torsional strength, and T-shaped joint breakage, and achieves the effect of reducing bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

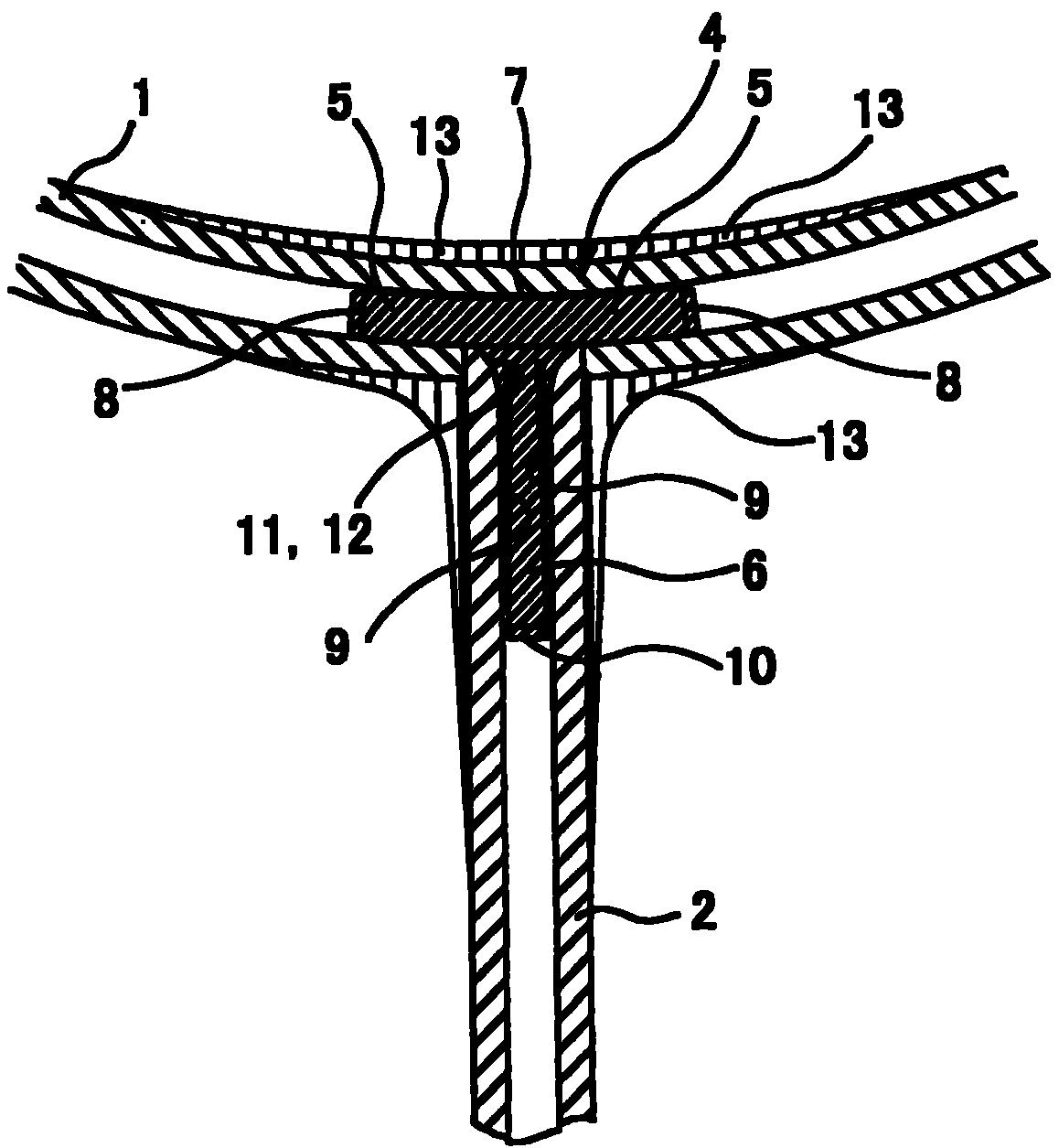

[0026] As shown in FIG. 1 , the badminton racket of the present invention generally includes a frame 1 , a rod 2 and a handle 3 .

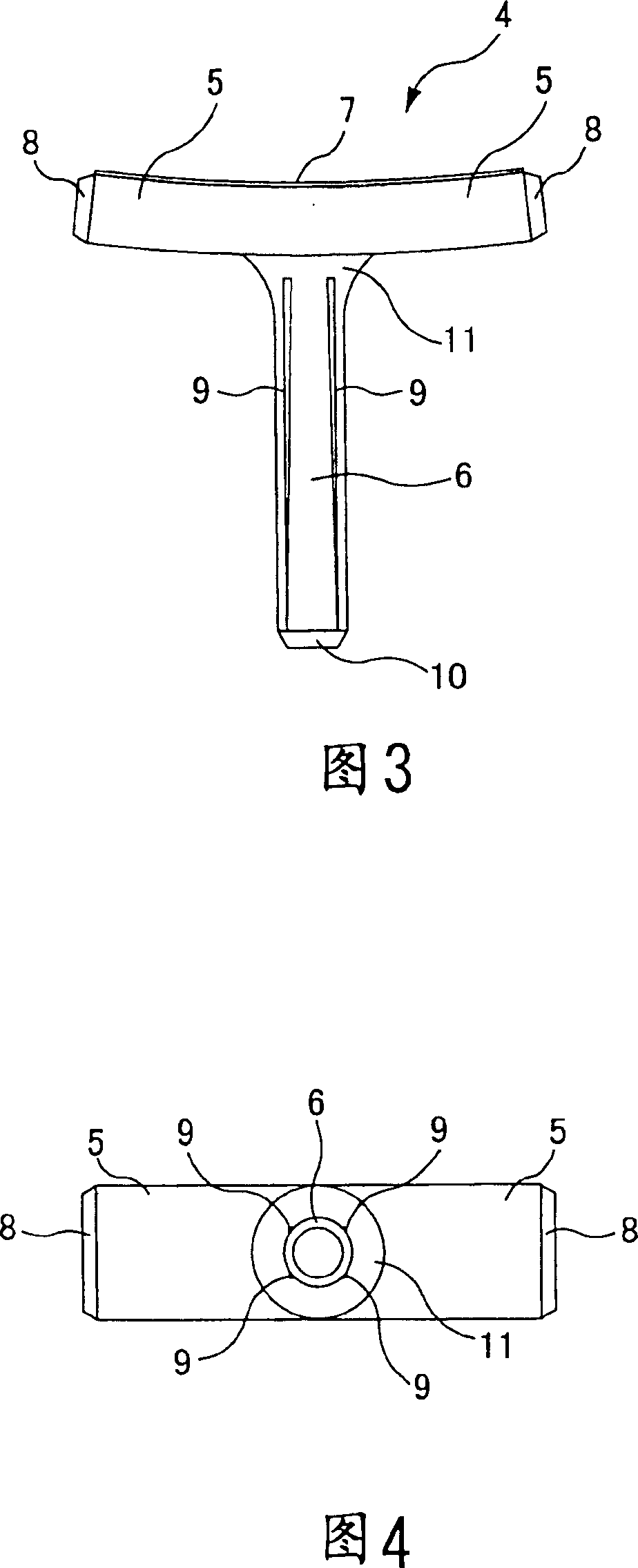

[0027] As shown in Figures 2 and 3, the frame 1 and rod 2 are connected together by a T-joint 4 inside the frame and rod.

[0028] The frame 1 and rod 2 are hollow tube structures, they are made of FRP, which is mainly made of carbon fiber. The T-joint 4 is made of metal such as aluminum alloy.

[0029] The T-joint 4 comprises a generally horizontal arm 5 and a vertical rod 6 extending downwards from the center of the arm. The horizontal arm 5 has an elliptical cross-section like the frame 1 and the vertical rod has a circular cross-section like the rod 2 .

[0030] A rib (small raised strip) 7 is formed along the central portion of the upper surface of the horizontal arm 5 and extends over the entire length of this surface. Preferably, the height of the rib decreases towards its ends so that the arms can be easily inserted into the opposite op...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com