Device for feeding organic plant material into the cutting zone of a cutting machine particularly for tobacco

A technology of plant material, cutting equipment, applied in the field of cutting area devices, tobacco devices, organic plant materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

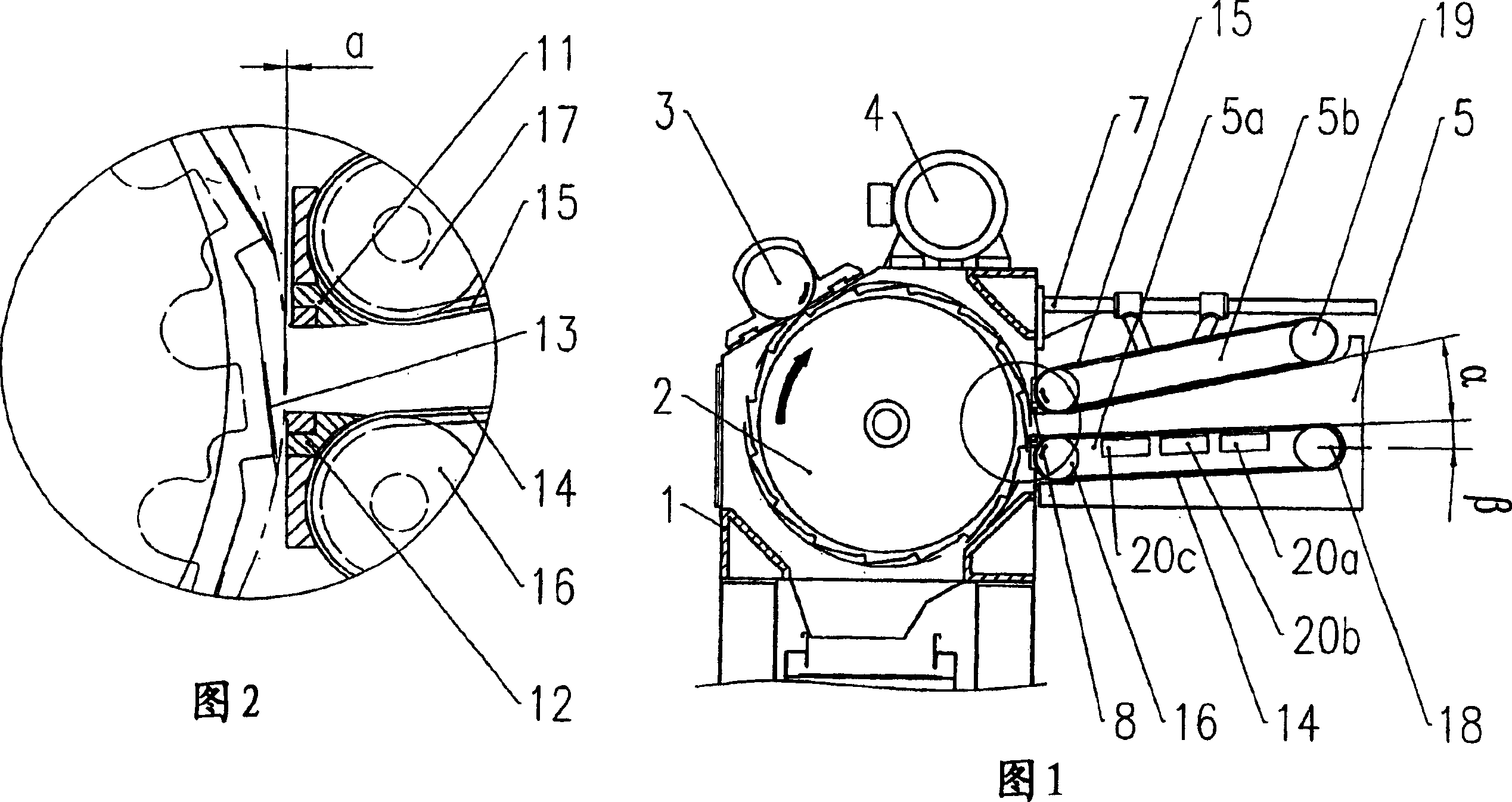

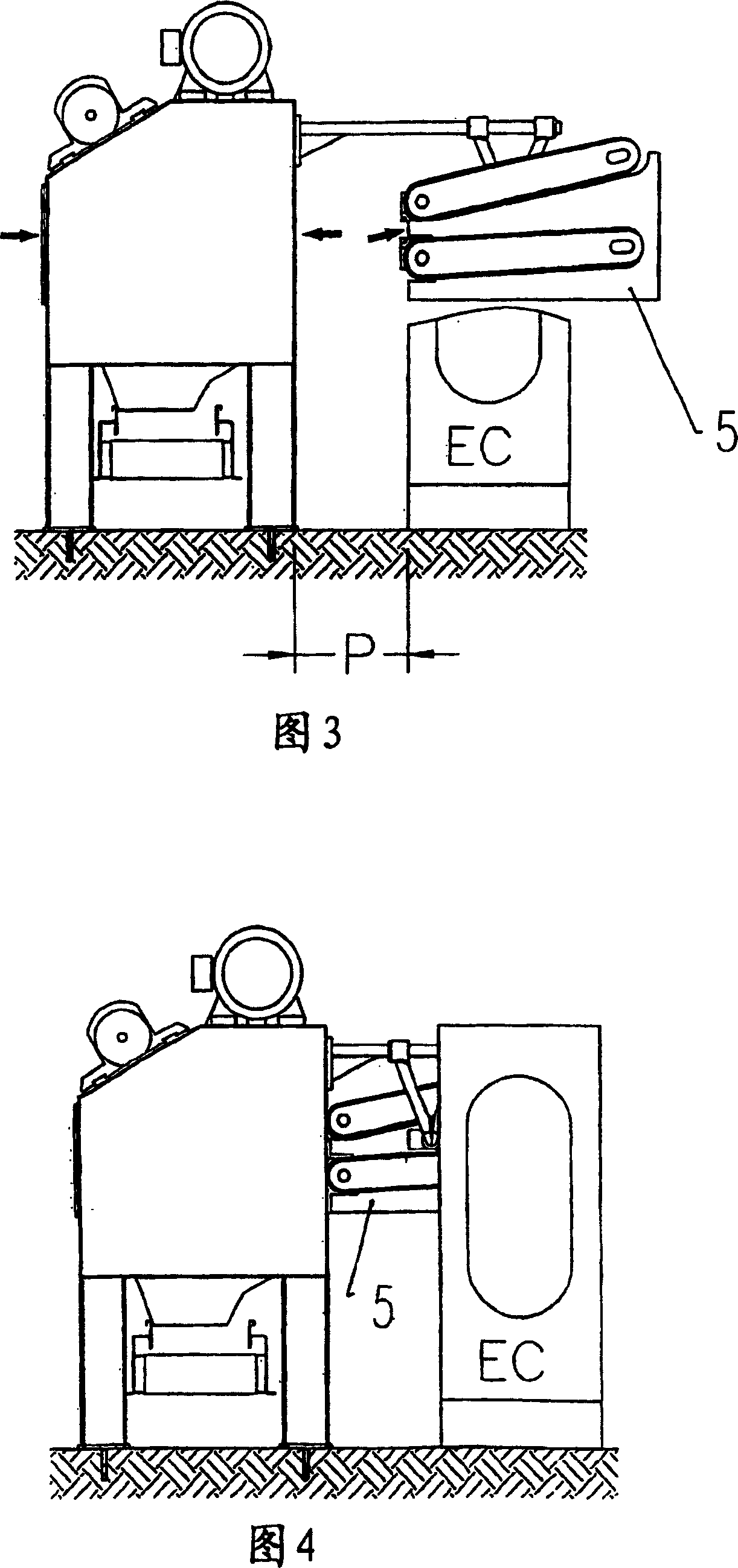

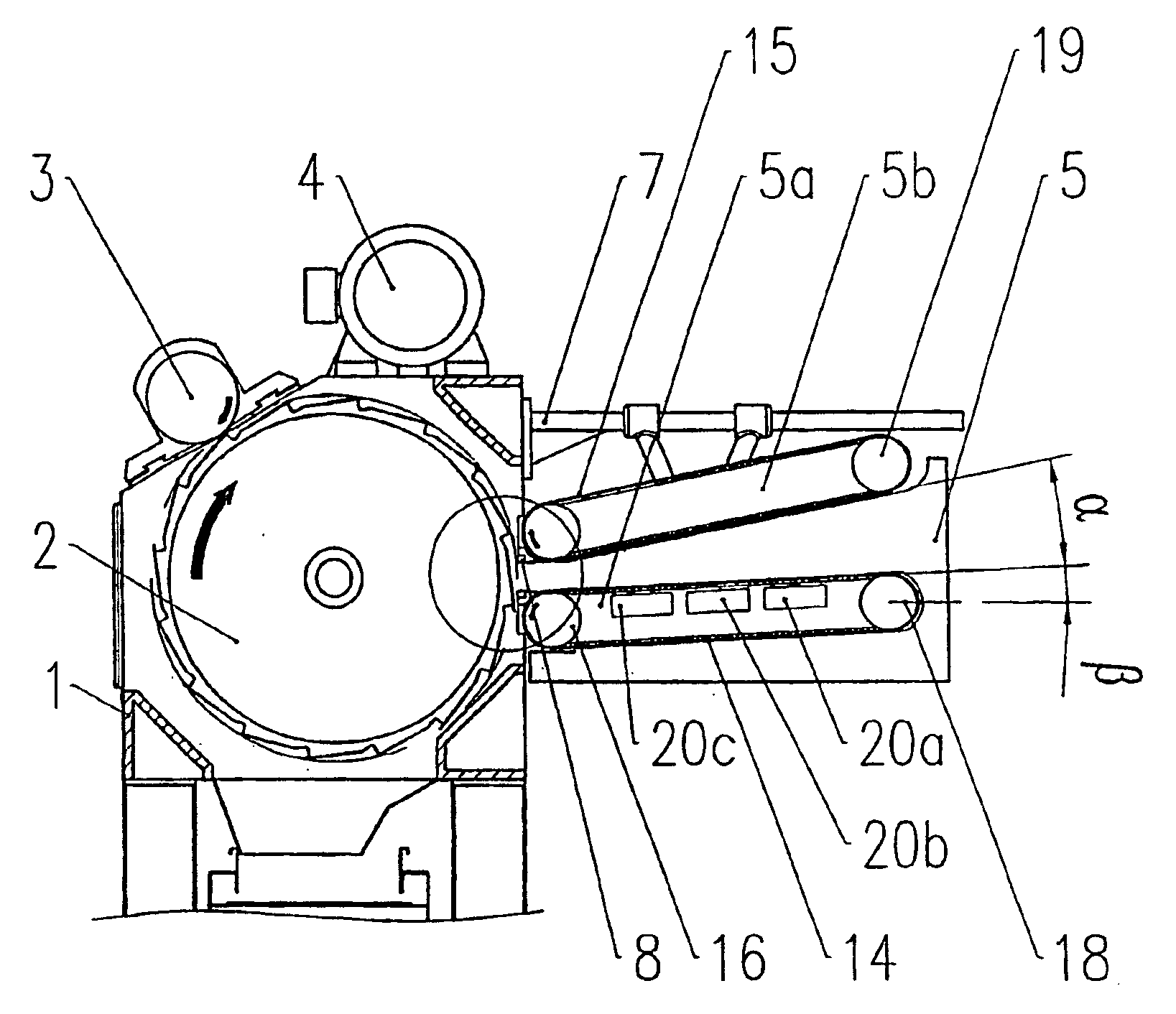

[0040] In the solution shown in Figure 1, the device comprises a conveying device 5 which conveys the moist tobacco material to the cutting / crushing zone; this device and its whole are not permanently fixedly attached to the body 1 of the cutterhead 2 . It may be preferred that the transfer device 5 is provided with an upper conveyor 5b located above the main conveyor 5a.

[0041] Both the main conveyor 5a and the upper conveyor 5b are provided with conveyor belts.

[0042] As shown in Figure 2, the main task of the main conveyor 5a and the upper conveyor 5b is to advantageously form and convey a strand of material to a nearby point and / or to the cutting / crushing zone.

[0043] The positions of the main conveyor 5a and the upper conveyor 5b have an adjustable mutual convergence point with an angle α towards the exit direction of the conveyed material, the working (upper) surface of the conveyor belt of the main conveyor 5a is at an angle of -10 to the horizontal ° to an angl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap