Voltage compensator capable of avoiding conduction-through for thyristor

A voltage compensation and thyristor technology, which is applied in the field of contactless AC voltage compensation and voltage regulation, can solve the problems of poor AC voltage compensation, short service life and high heat, and achieves energy saving, long service life and good compensation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

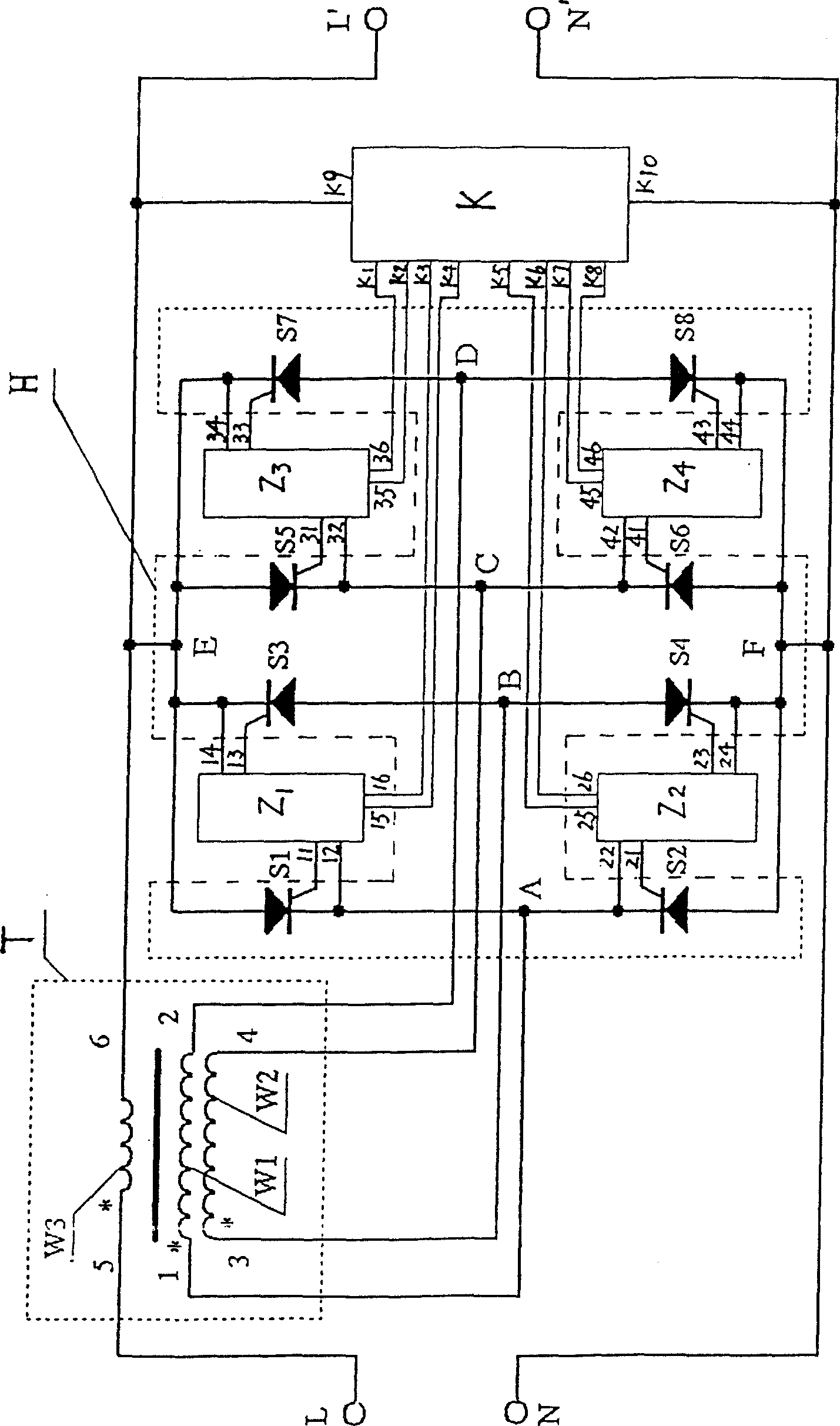

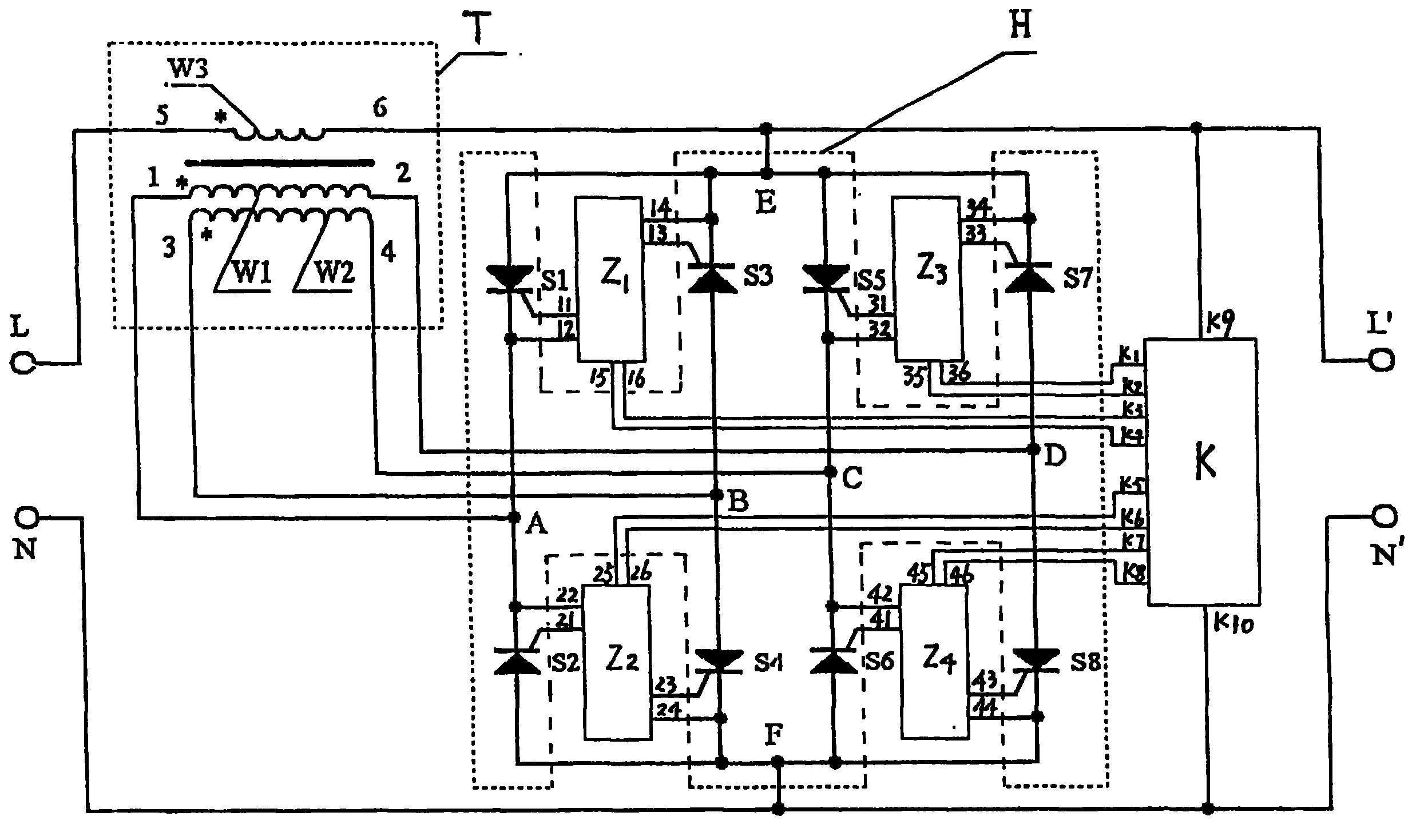

[0011] The voltage compensation device capable of avoiding thyristor straight-through of the present invention has a compensation transformer T and a thyristor bridge, and the primary winding of the compensation transformer T is composed of at least two sets of first winding W1 and second winding W2 with the same number of turns; the thyristor bridge The circuits are composed of at least eight unidirectional thyristors, namely: the first unidirectional thyristor S1, the second unidirectional thyristor S2, the third unidirectional thyristor S3, the fourth unidirectional thyristor S4, the fifth unidirectional thyristor S5, and the sixth unidirectional thyristor. The thyristor S6, the seventh unidirectional thyristor S7, and the eighth unidirectional thyristor S8 are divided into two groups to form a thyristor bridge group H;

[0012] The first unidirectional thyristor S1 and the second unidirectional thyristor S2 are cathode-connected A-terminals connected to the head end 1 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com