Extreme pressure cutting fuild microemulsion free of chlorine and its preparation method and uses

A cutting fluid, extreme pressure technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of strong corrosion of machine tool paint, shortening the service life of cutting fluid, poor oil discharge performance, etc., to improve the corrosion performance of machine tool paint, reduce The effect of improving waste liquid discharge and oil discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

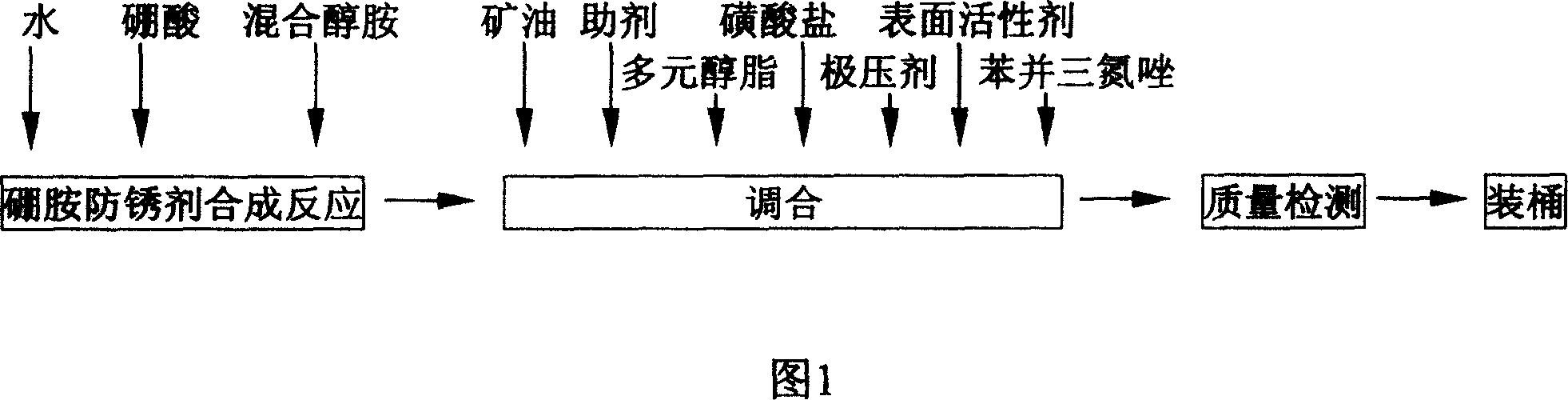

[0045] Prepare the chlorine-free extreme pressure microemulsion cutting fluid of the present invention according to the process flow diagram shown in Fig. 1, and its steps are:

[0046] 1) Synthesis of boron amine rust inhibitor

[0047] Add 4 g of boric acid, mixed alcohol amine (by weight, diethanolamine: triethanolamine = 90: 10) 8 g, tap water (hardness of tap water is not higher than 250 ppm) 35 g into the reaction tank, stir at 10 ° C for 60 minutes, the solution is transparent , No sediment.

[0048] 2) In the reaction tank, add the remaining components according to the proportion of the formula, the sulfonate rust inhibitor is 10g of 50% petroleum sodium sulfonate, the anionic surfactant sulfonated rapeseed oil soap 8g, and the polyol ester is polyol lauric acid 4g of ester, 4g of sulfurized fatty acid ester containing 15% sulfur, oil separation aid is fatty alcohol polyoxyethylene ether MOA 3 (Its HLB value is not greater than 6) 2g, mineral oil has a kinematic visc...

Embodiment 2

[0050] Prepare the chlorine-free extreme pressure microemulsion cutting fluid of the present invention according to the process flow diagram shown in Fig. 1, and its steps are:

[0051] 1) Synthesis of boron amine rust inhibitor

[0052] Add 5 g of boric acid, 10 g of mixed alcohol amines (by weight, diethanolamine:triethanolamine=80:20), and 30 g of distilled water into the reaction tank, and stir at 28° C. for 35 minutes. The solution is transparent and free of precipitates.

[0053] 2) In the reaction tank, add the remaining components according to the formula ratio, the sulfonate rust inhibitor is 8g of 40% petroleum sodium sulfonate, the anionic surfactant sulfonated castor oil soap 10g, and the polyol ester is polyol oleic acid 6g of ester, 6g of sulfurized fatty acid ester containing 10% sulfur, oil separation aid is fatty alcohol polyoxyethylene ether MOA3 (The HLB value is not greater than 6) 3g, mineral oil is kinematic viscosity (40 ℃) is 32mm 2 / s of naphthenic oi...

Embodiment 3

[0055] Prepare the chlorine-free extreme pressure microemulsion cutting fluid of the present invention according to the process flow diagram shown in Fig. 1, and its steps are:

[0056] 1) Synthesis of boron amine rust inhibitor

[0057] Add 3 g of boric acid, 7 g of mixed alcohol amines (by weight, diethanolamine:triethanolamine=70:30), and 32 g of deionized water into the reaction tank, and stir at 22° C. for 45 minutes. The solution is transparent without sediment.

[0058] 2) In the reaction tank, add the remaining components according to the formula ratio, the sulfonate rust inhibitor is 9g of 60% petroleum sodium sulfonate, the anionic surfactant sulfonated rapeseed oil soap 9g, and the polyol ester is polyol oleic acid 5g of ester, 5g of sulfurized fatty acid ester containing 17% sulfur, oil separation aid is fatty alcohol polyoxyethylene ether MOA 3 (Its HLB value is not greater than 6) 1g, mineral oil has a kinematic viscosity (40°C) of 20mm 2 / s naphthenic oil 28.9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com