Oxidizing device for producing aromatic carboxylic acid

An oxidation device, aromatic carboxylic acid technology, applied in carboxylate preparation, organic chemistry, chemical instruments and methods, etc., can solve the problems of large gas processing capacity and solvent evaporation, reduction of liquid foam entrainment, high superficial gas velocity, etc. , to achieve the effect of increasing gas-liquid contact efficiency, increasing plate efficiency, and simple tray structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

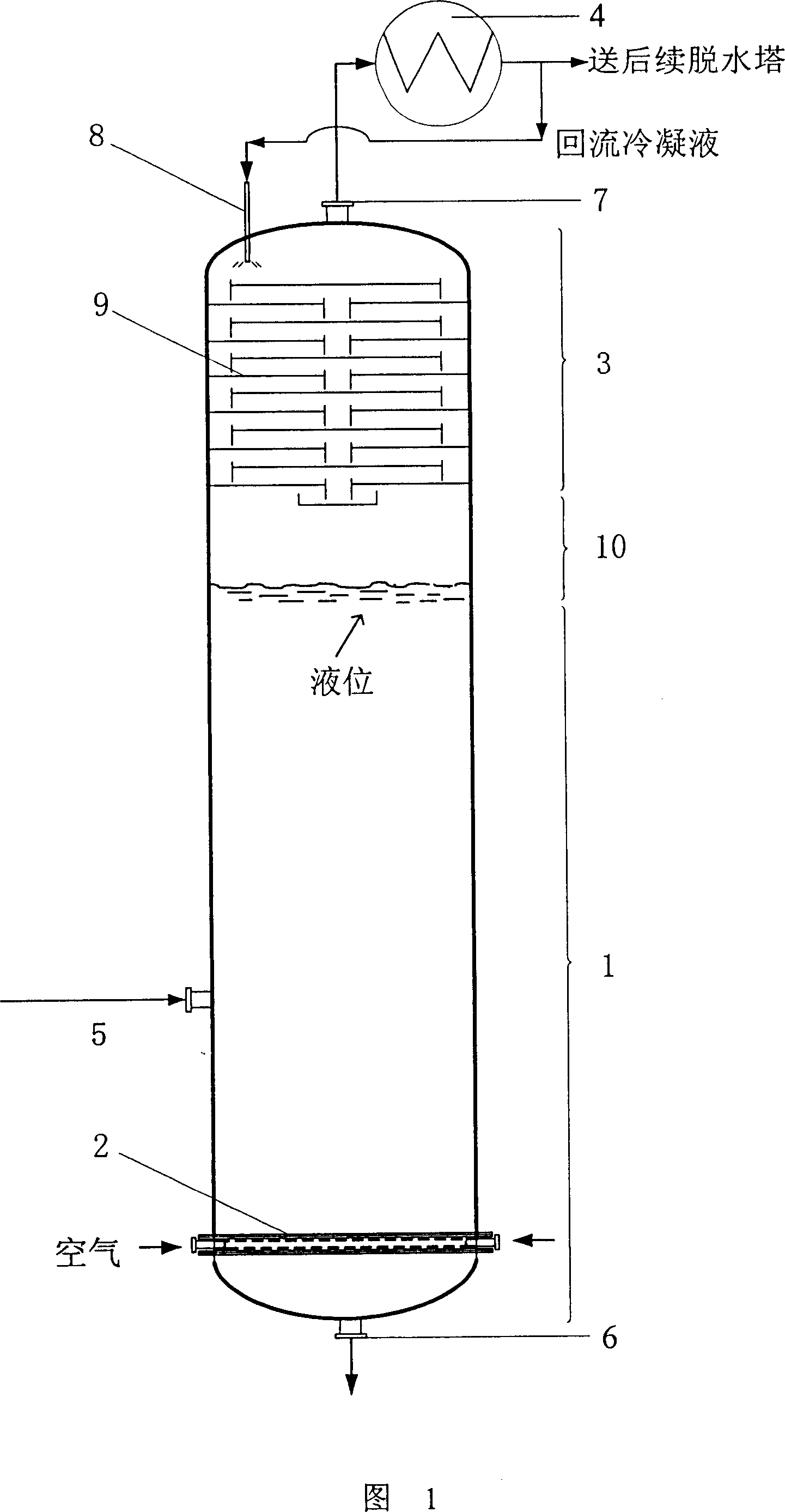

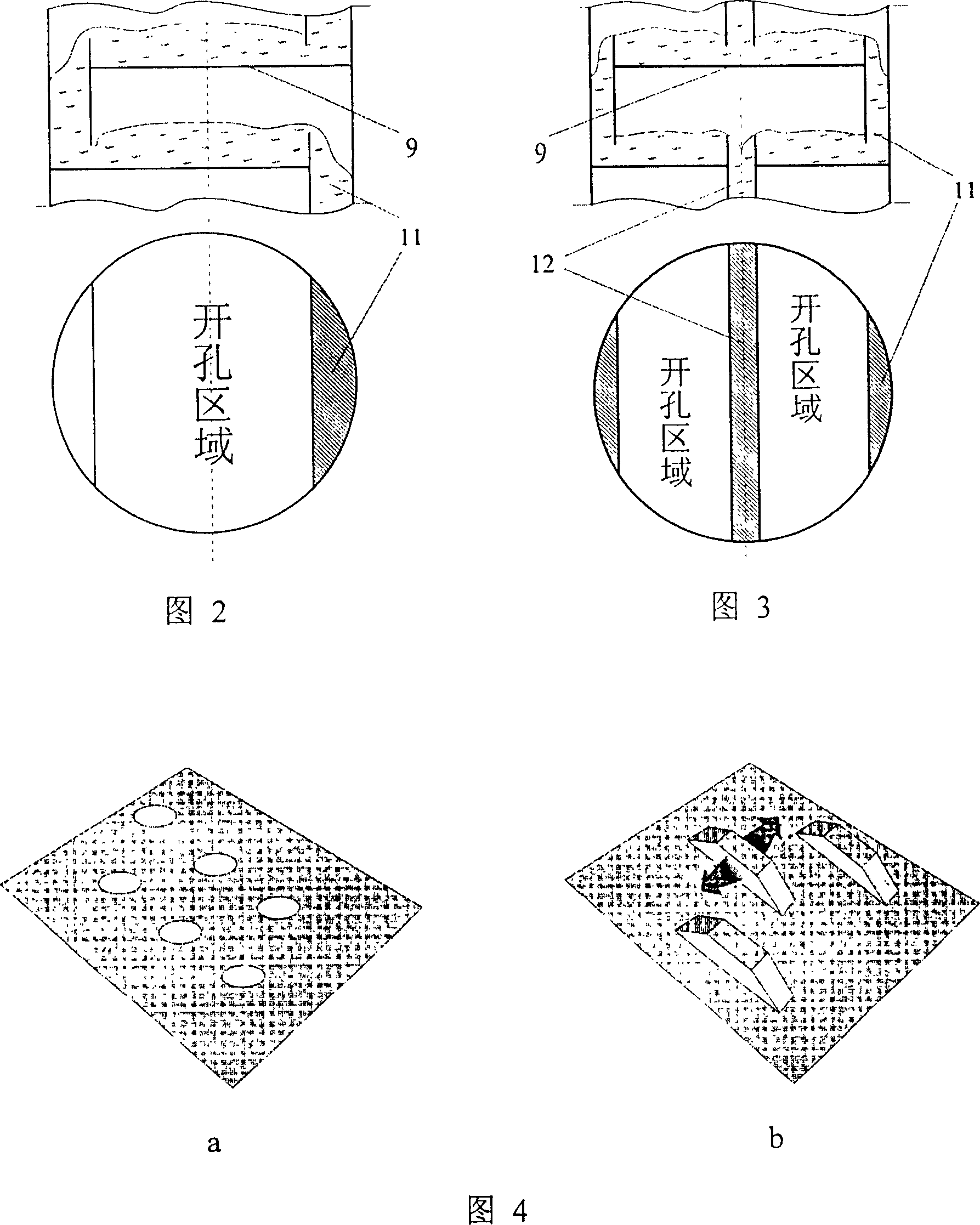

Embodiment 1

[0024]The reaction section adopts a bubble column, and the gas separation section adopts multi-layer large-aperture sieve plates. Due to the large gas-liquid flow rate of the several layers of trays located in the lower part of the separation section, the plate spacing and opening ratio are 500mm and 15% respectively; The gas-liquid flow rate of several layers of trays located in the upper part of the separation section is small, so the plate spacing and opening ratio are reduced, which are 450mm and 11% respectively. The reaction conditions are listed in Table 1, the structural parameters of the reactor are listed in Table 2, the output indicators of the liquid phase of the reaction section are listed in Table 3, and the output indicators of the gas separation section are listed in Table 4.

[0025] Table 1 oxidation reaction conditions

[0026]

PX processing capacity

(ton / hour)

reaction pressure

Mpa (absolute pressure)

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com