Method for producing cotton comforeter batt without gauze and machine for milling cotton

A manufacturing method and quilt technology, applied in non-woven fabrics, felting equipment, textiles and papermaking, etc., to achieve the effects of ensuring continuity, easy promotion and popularization, and rapid skin formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

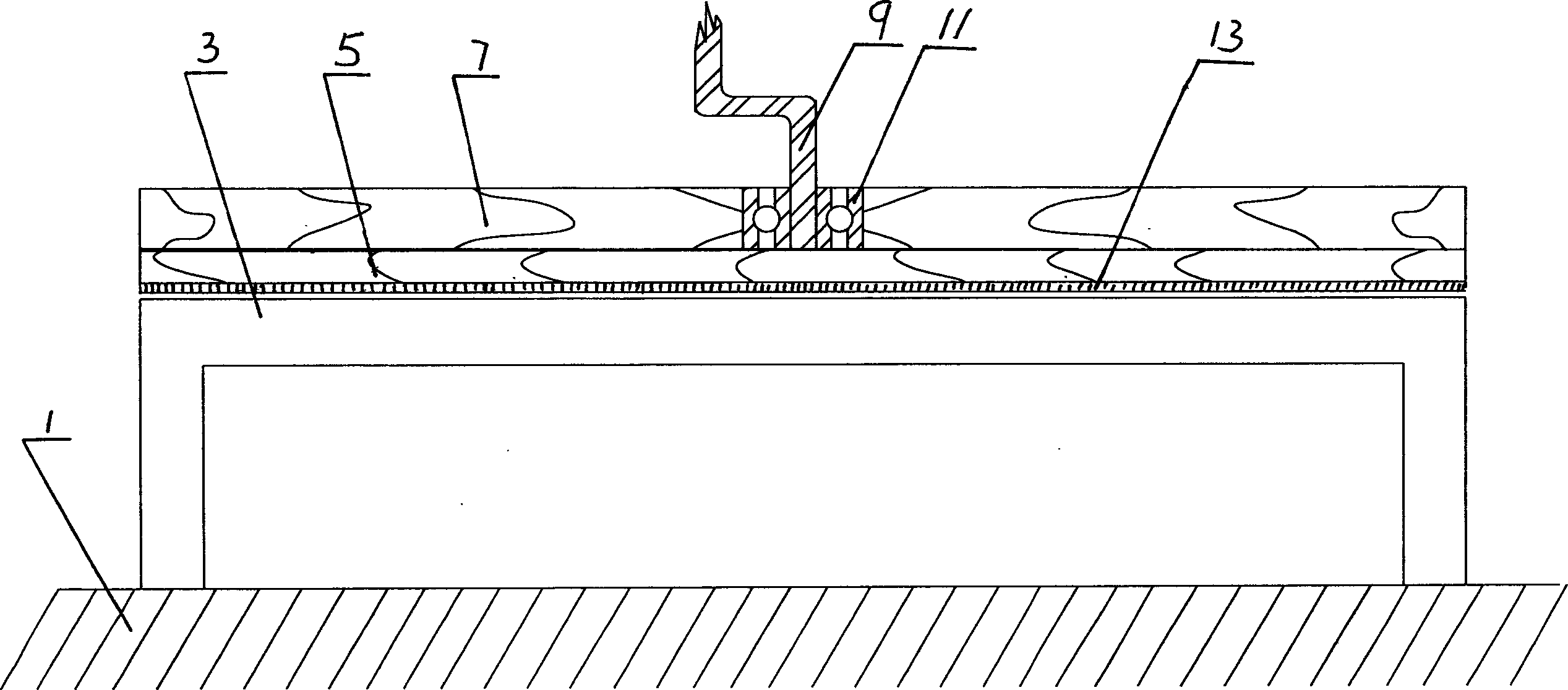

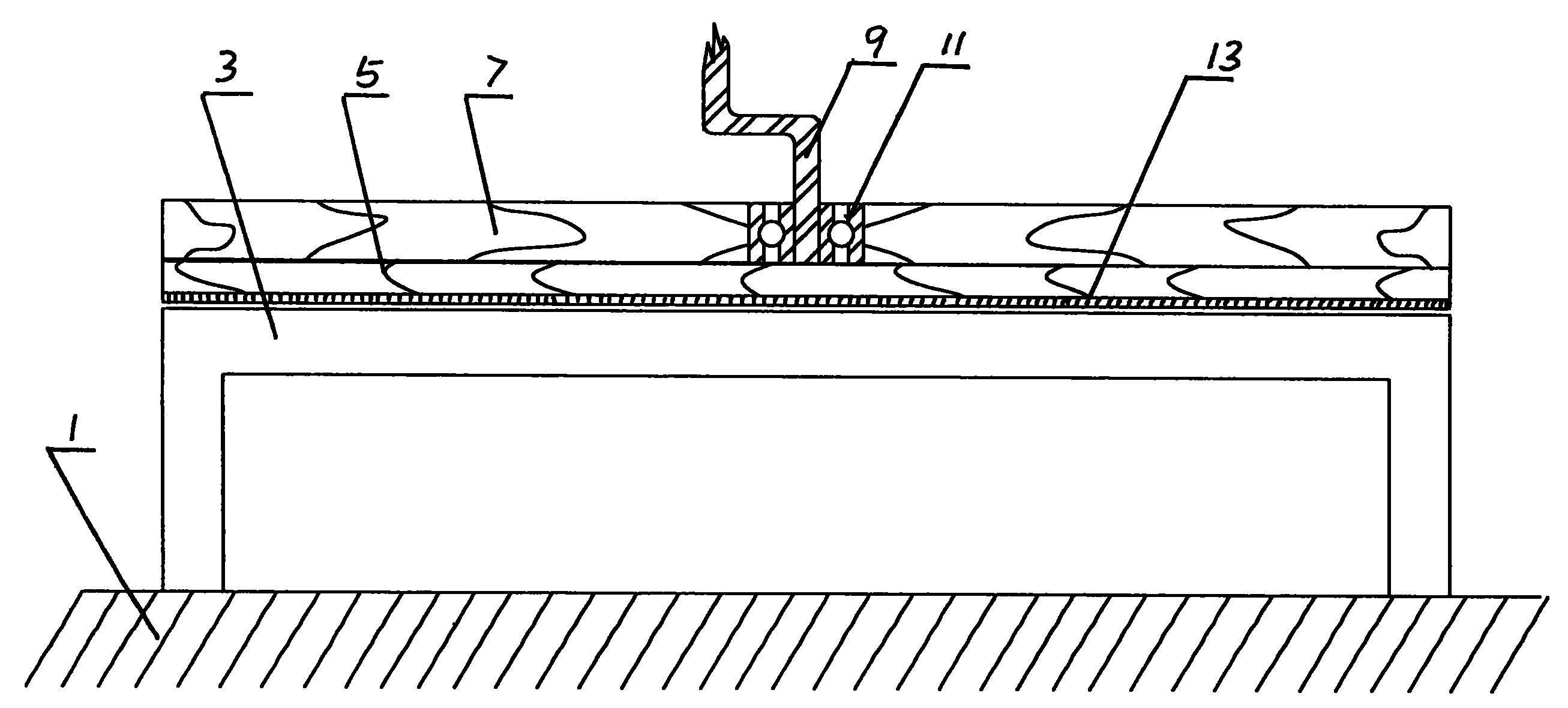

[0037] The present invention will be further described below. Hereby take the production of a non-gauze quilt with a weight of 3Kg and a length of 2 meters and a width of 1.5 meters as an example. The method is as follows: (1) Comb the lint cotton into rolls in accordance with the national first-class standard. The lint that meets the national first-level standard is combed on a carding machine with a width of 1 meter. When feeding the cotton, it is carried out in a roll with a weight of 0.3Kg, and the length is controlled according to the width of the quilt to be processed. In this way, 10 rolls of carded cotton with a width of 1 meter and a length of 1.5 meters were obtained. (2) Spread and flatten. Unfold the rolled carded cotton on the working platform of the cotton mill. When spreading, it is carried out according to the size of 2 meters long and 1.5 meters wide. The carded cottons of the same layer have the same direction, and the edges of adjacent carded cottons sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com