Pressing unit for separating the diecut blanks of a sheet

A pressing device, die-cutting technology, applied in the direction of peeling device, sending objects, transportation and packaging, etc., can solve the problem of long pressure track

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

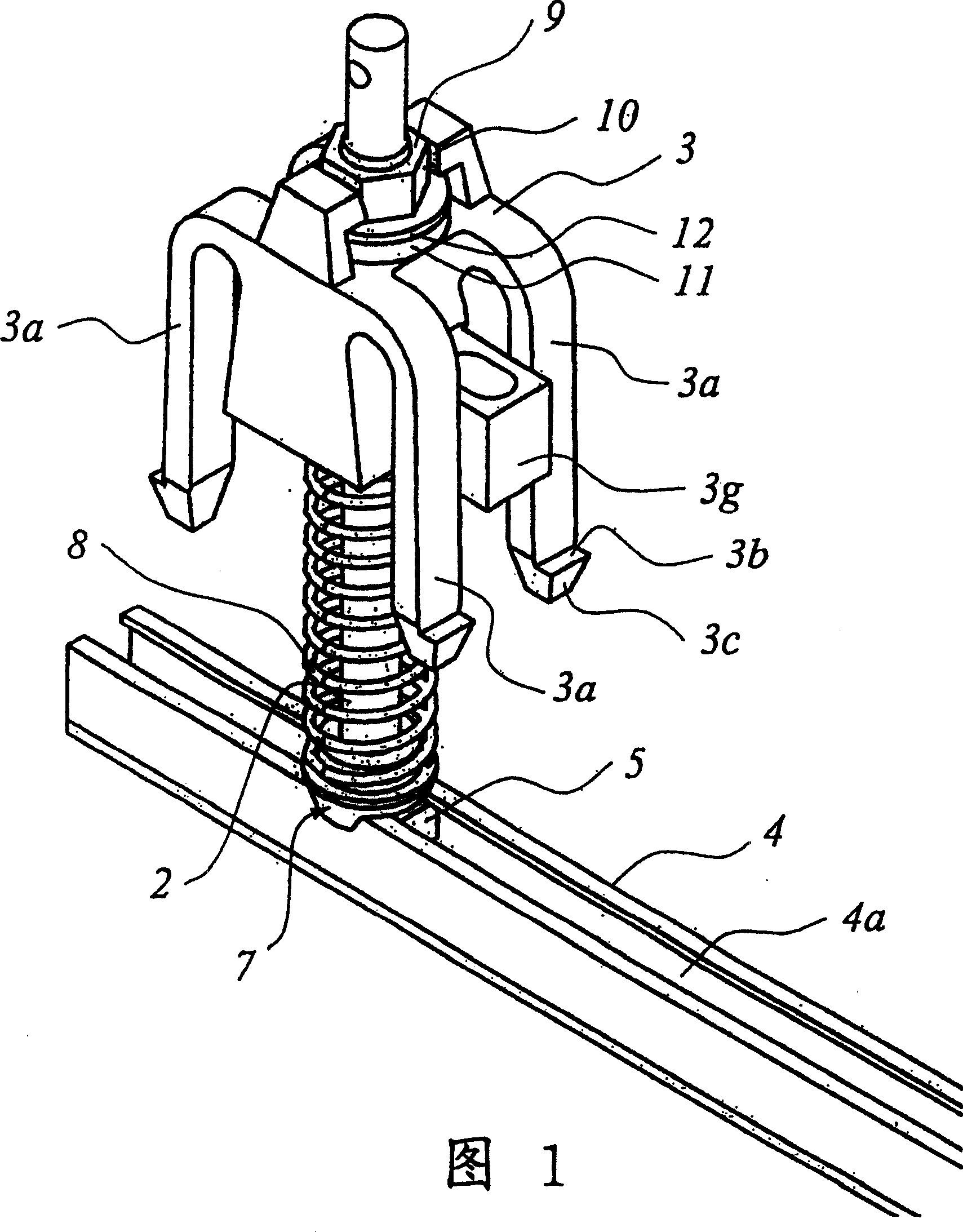

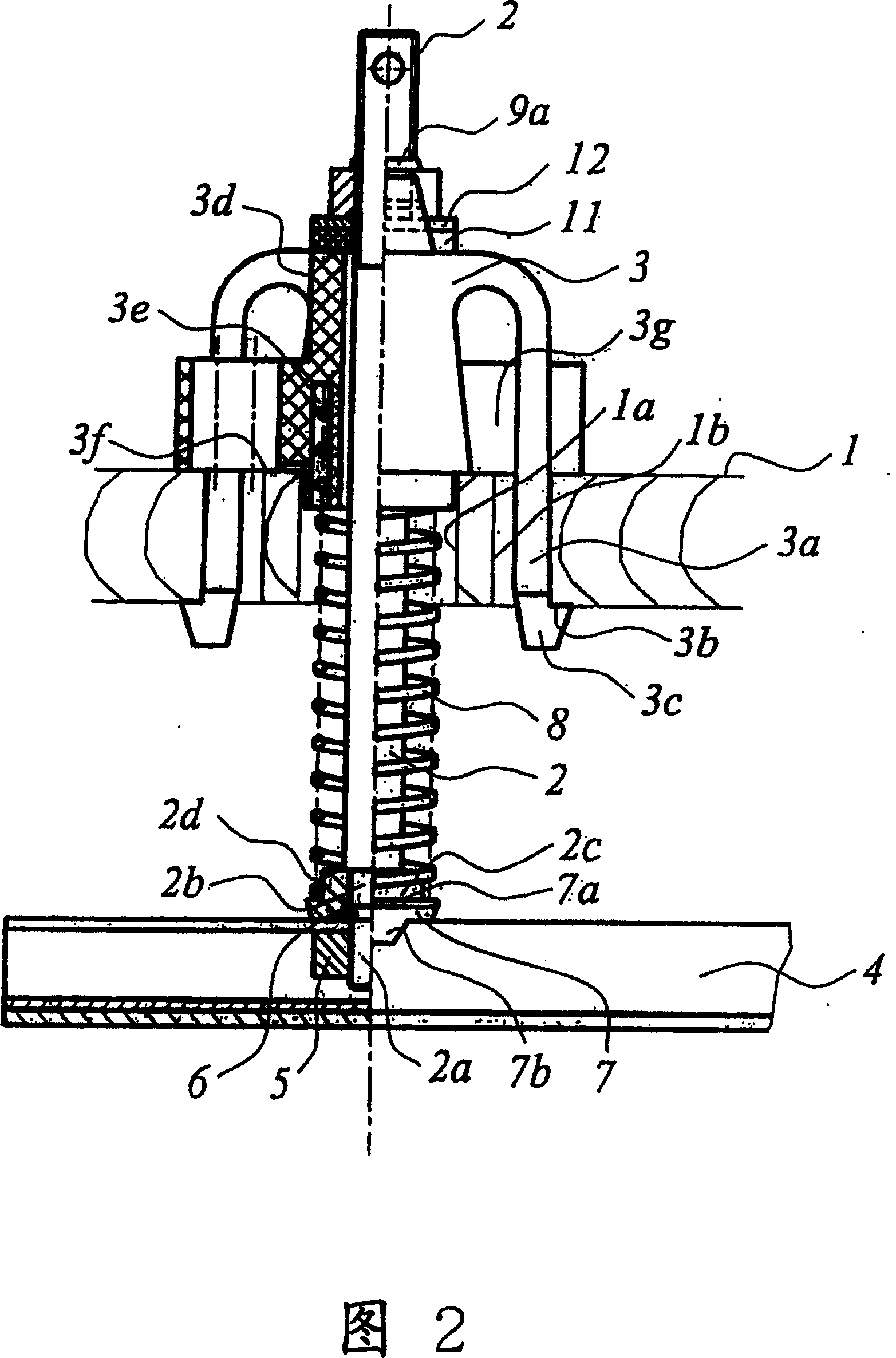

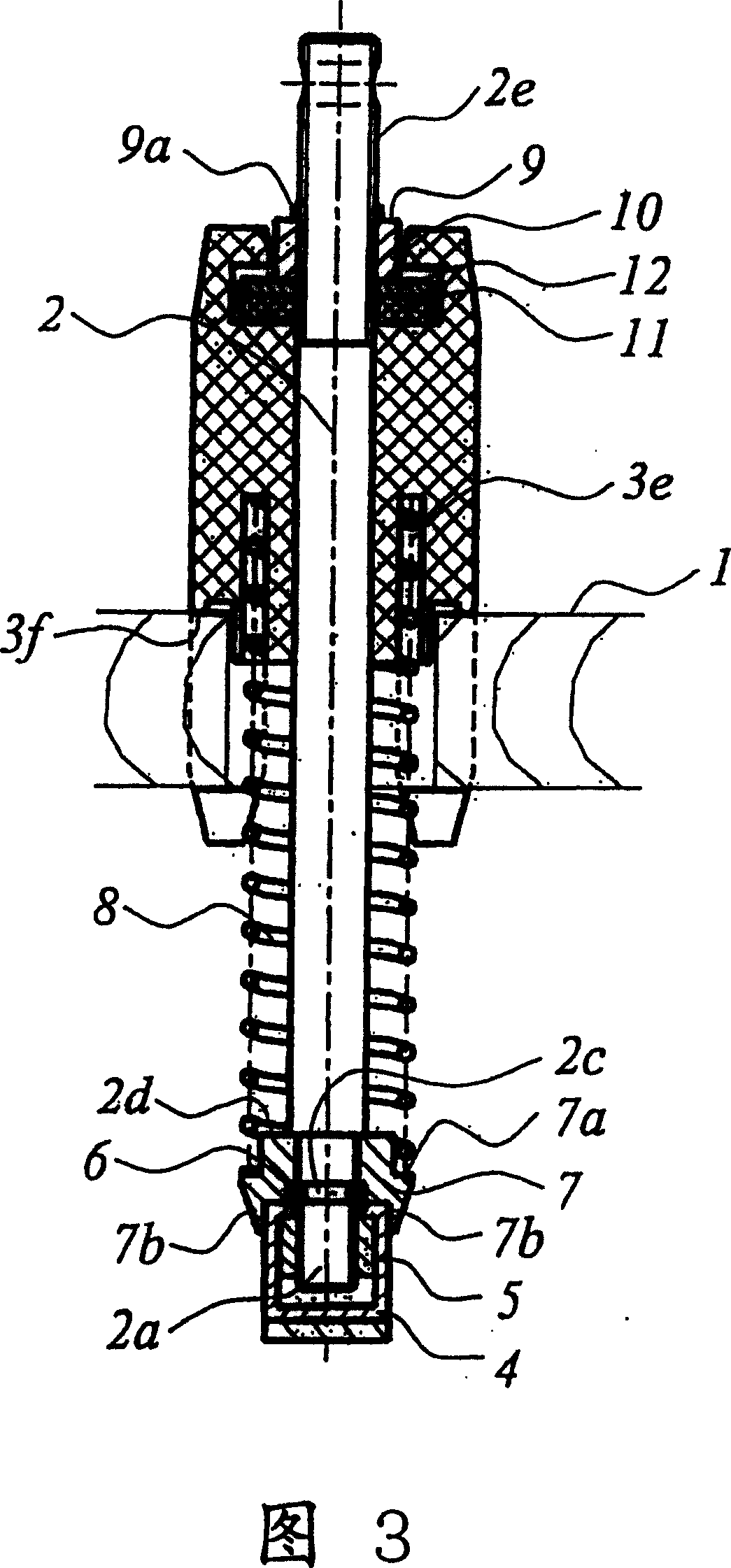

[0019] The pressing device of the present invention comprises a horizontal upper support 1, in this embodiment, the upper support 1 is made of a wooden board with a hole 1a for moving the sliding rod 2, only drawn in the figure Out came a slide bar. The sliding rod 2 is mounted so as to slide in a connecting device 3 . The connecting device 3 comprises four deformable clamping claws 3 a which pass through four holes 1 b of the upper support 1 . These deformable clamping jaws 3a terminate in a bearing or stop surface 3b which extends towards the outside of the deformable clamping jaws 3a. Said bearing surface is adjacent to a locking surface 3c which is inclined towards the inside of said deformable claw 3a.

[0020] Since the deformable clamping jaws 3a are slightly inclined with respect to their free state in the clamping position of the support plate 1, when in the clamping position of the connecting device 3, the stop surface 3b is parallel to the support plate 1, ensuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com