Composite concrete building casing member and plate, and their combining method

A construction box and composite concrete technology, applied in the direction of building structure, architecture, small buildings, etc., can solve the problems of hindering survival and development, large on-site work, difficult to popularize and apply, etc., to facilitate mechanized production and on-site work. Small, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

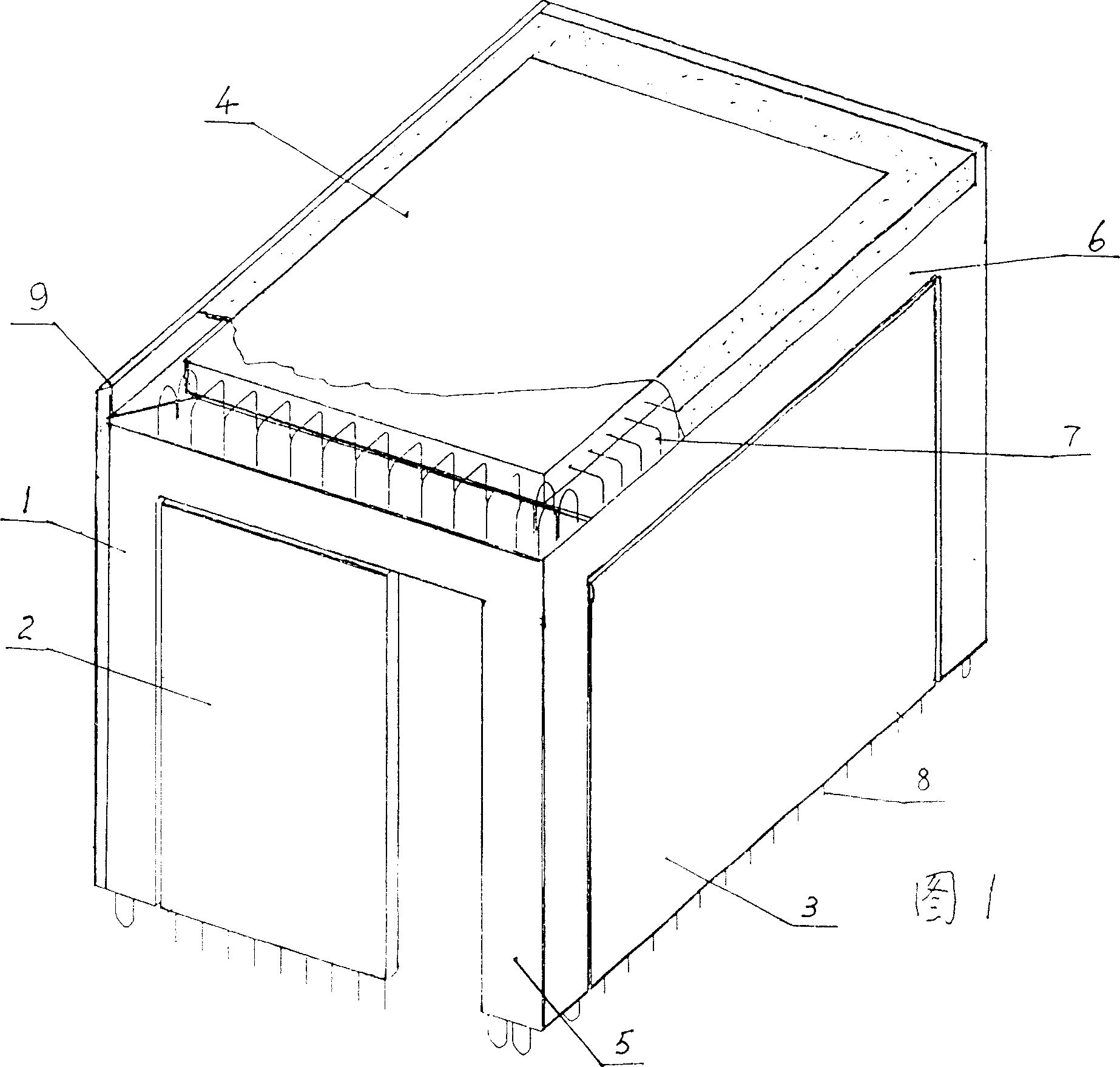

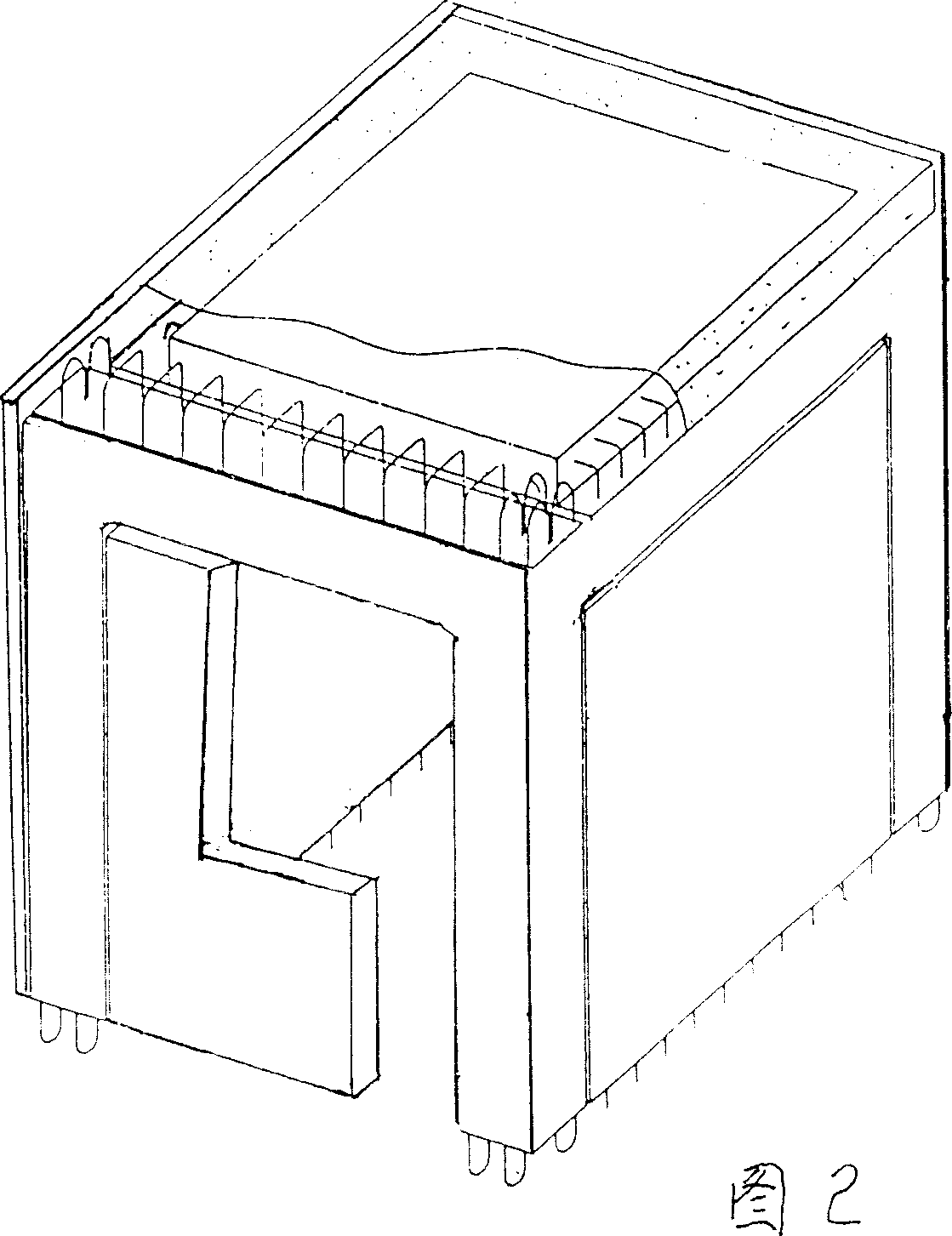

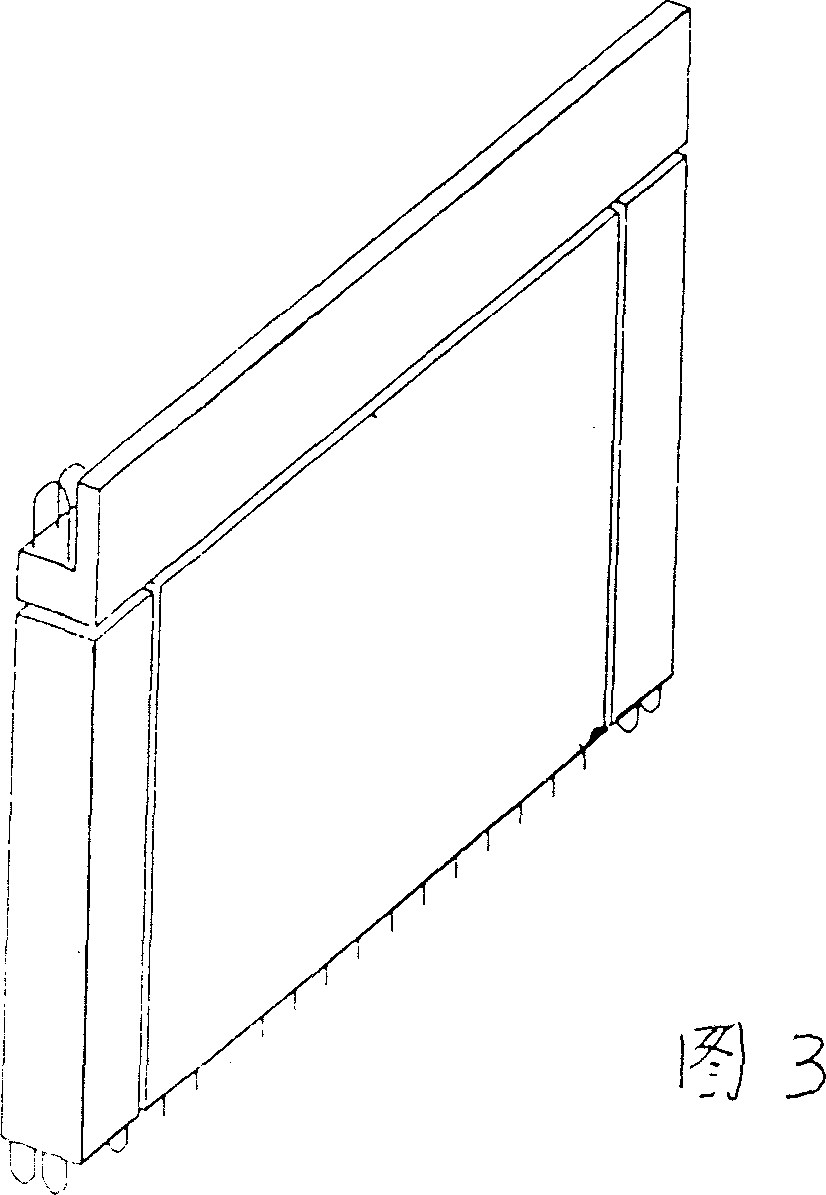

[0018] It can be known from the above-mentioned accompanying drawings that a specific structure of the present invention: its box-type member is a five-sided light concrete structure 1, and the front, rear, left and right four-sided light concrete walls 2, 3 of aerated reinforced concrete with autoclaved fly ash , one side of the autoclaved fly ash aerated reinforced concrete light concrete roof 4 and ordinary concrete columns 5, beams 6 and rib beams (slab ribs) (not shown), by means of the connecting ribs 7 and 8 in the ribs to insert and butt, The formwork is cast with ordinary concrete into a whole, and a polystyrene foam insulation board 9 with a thickness of 5 cm is installed on the exposed surface of the component.

[0019] The box-type light-concrete wall 2 and 3 and the floor-slab 4 components are produced according to the user's needs, and then the light-weight concrete components are inserted into the combined formwork according to the design requirements, and C25 or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com