Continuous method for preparing syndiotactic polyvinyl aromatic hydrocarbon

A technology of polyvinyl aromatics and vinyl aromatics, which is applied in the continuous field of preparing syndiotactic polyvinyl aromatics, can solve the problems of high stirring power, poor heat transfer, and low utilization of reactors, and achieve good technical effects and utilization rate-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

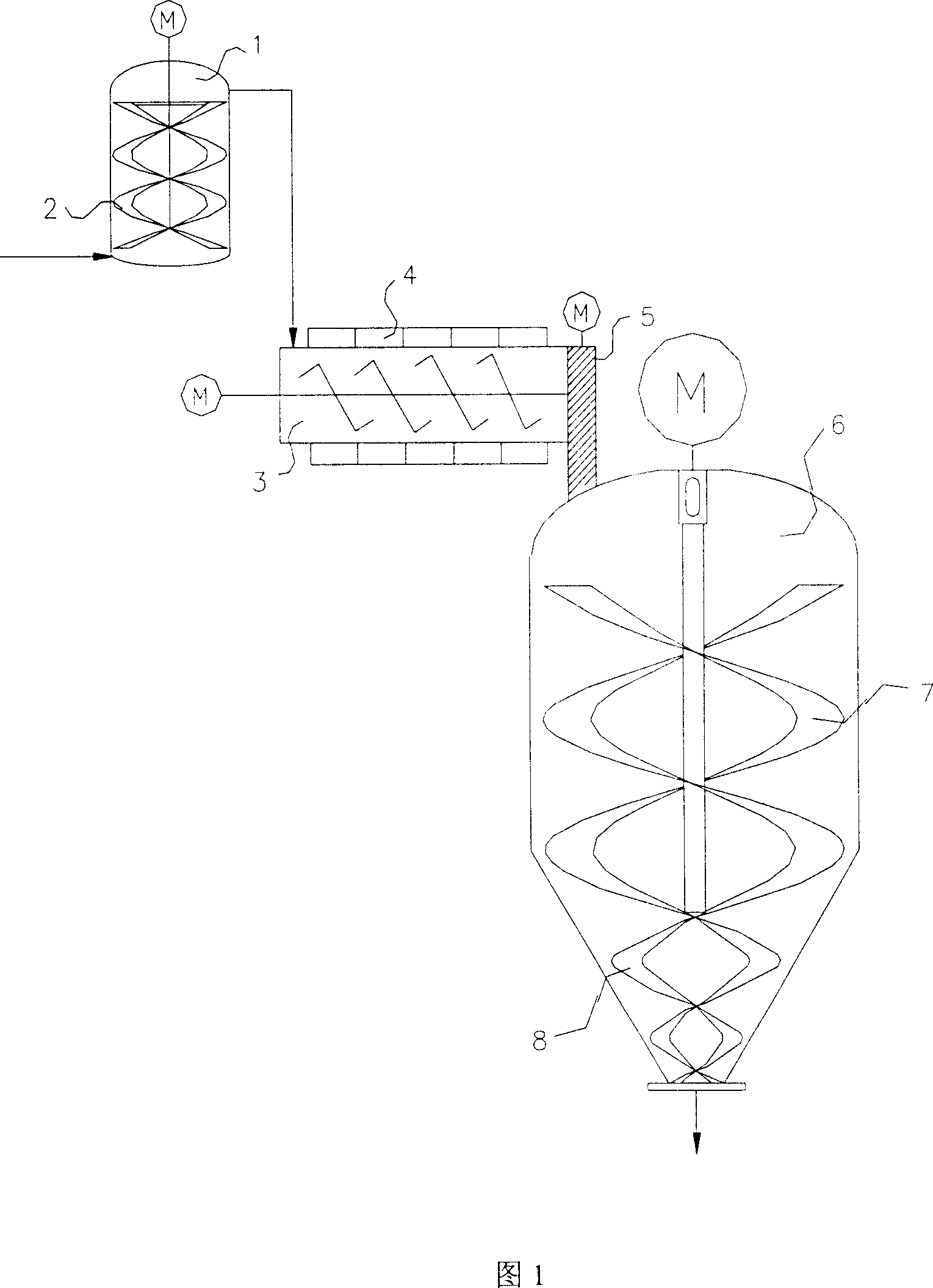

[0025] The three reactors described in the present invention are respectively composed of a 10-liter vertical prepolymerization kettle, a 10-liter horizontal double-shaft self-cleaning kettle and a 100-liter vertical conical reactor. First vacuum bake the three reactors and corresponding pipelines at 90°C for 8 hours, then lower the temperature to 60°C, and use N 2 After purging 3 times, open feed valve, make the flow of styrene monomer be 16 liters / hour, the flow of inert solvent hexane is 4 liters / hour, titanocene catalyst Cp * Ti(O-C 6 h 4 -OCH 3 ) 3 The flow rate is 1.4 mmol / h, the flow rate of methylaluminoxane MAO is 210 mmol / h, and the flow rate of triisobutylaluminum TIBA is 140 mmol / h. Start stirring at the same time, the stirring speed of 10 liters of pre-polymerization tank is 300 rev / min and the spiral belt presses down operation, the two screw rods in the self-cleaning reactor are different, one is the cleaning screw rod, the rotating speed is 30 rev / min, and ...

Embodiment 2

[0027] The three reactors described in the present invention are respectively composed of a 10-liter vertical prepolymerization kettle, a 10-liter horizontal double-shaft self-cleaning kettle and a 100-liter vertical conical reactor. First vacuum bake the three reactors and corresponding pipelines at 90°C for 8 hours, then lower the temperature to 60°C, and use N 2 After purging 3 times, open feed valve, make the flow of styrene monomer be 10 liters / hour, the flow of inert solvent hexane is 3 liters / hour, titanocene catalyst Cp * Ti(O-C 6 h 4 -OCH 3 ) 3 The flow rate is 1.2 mmol / h, the flow rate of methylaluminoxane MAO is 200 mmol / h, and the flow rate of triisobutylaluminum TIBA is 120 mmol / h. Start stirring at the same time, the stirring speed of 10 liters of pre-polymerization tank is 300 rev / min and the spiral belt presses down operation, the two screw rods in the self-cleaning reactor are different, one is the cleaning screw rod, the rotating speed is 30 rev / min, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com