Steel concrete assembled beam by asymmetric section steel beam

A concrete and asymmetric technology, applied in the field of composite beams, can solve the problems of prolonging the construction period and increasing the construction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

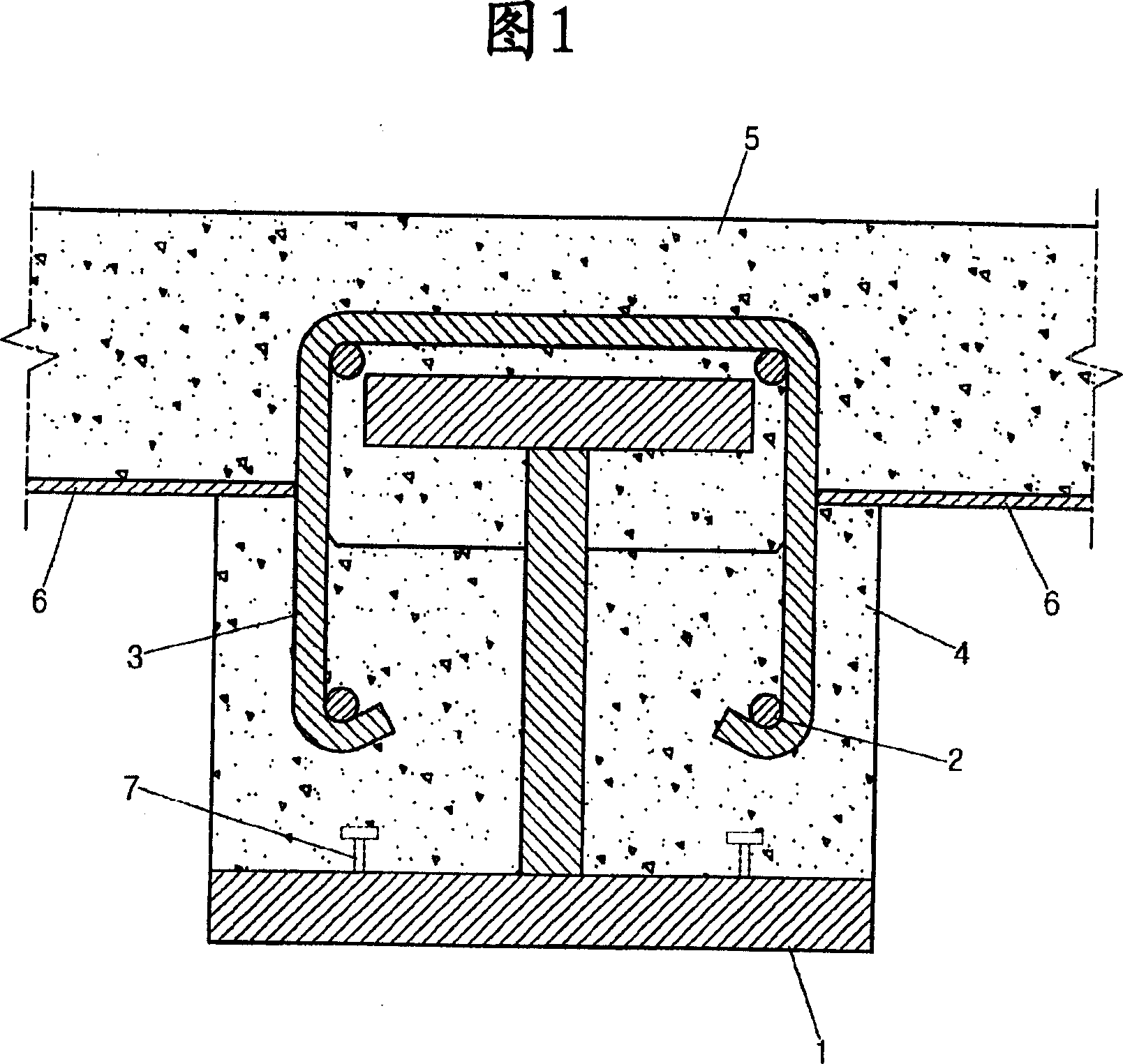

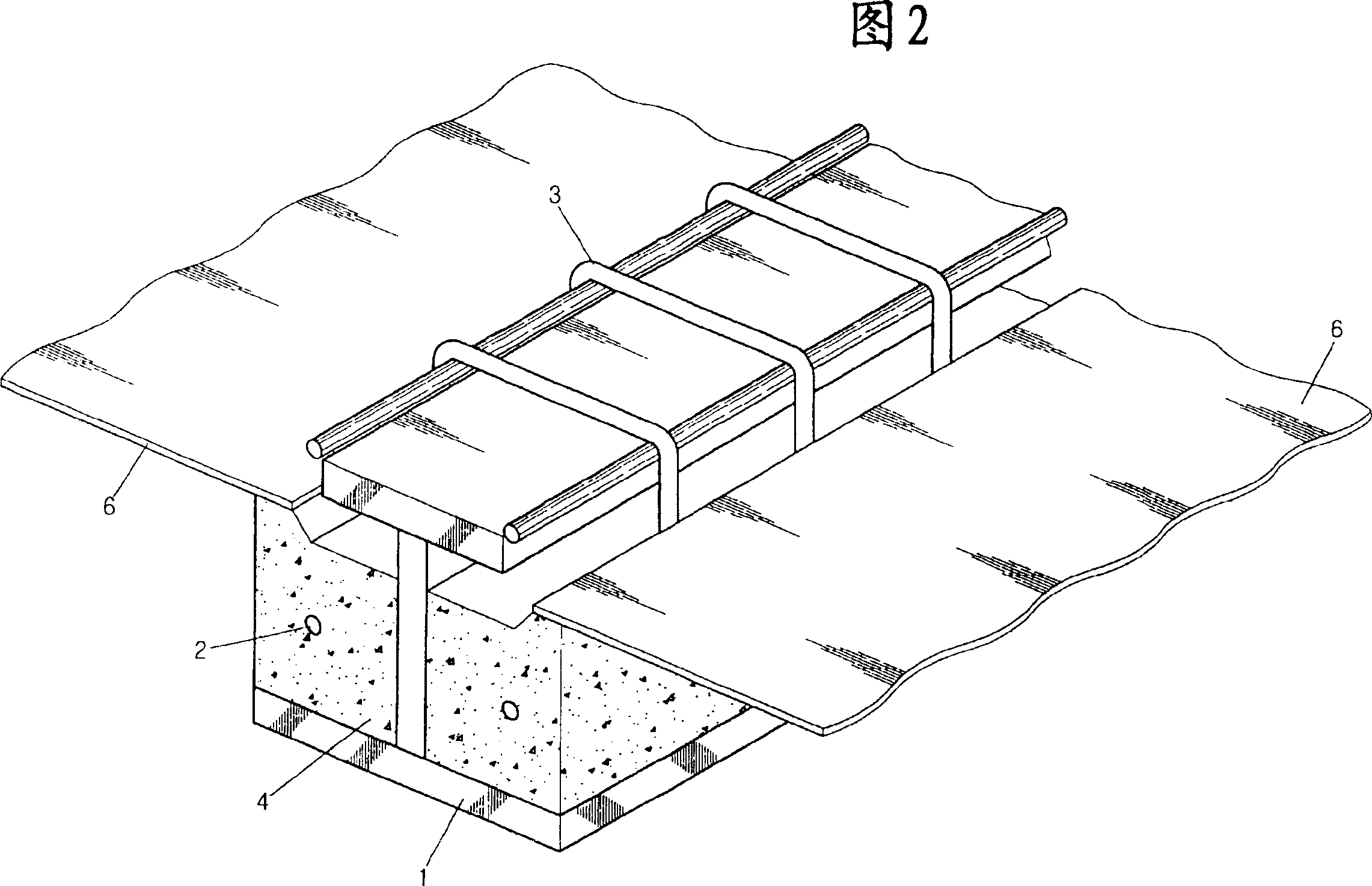

[0021] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

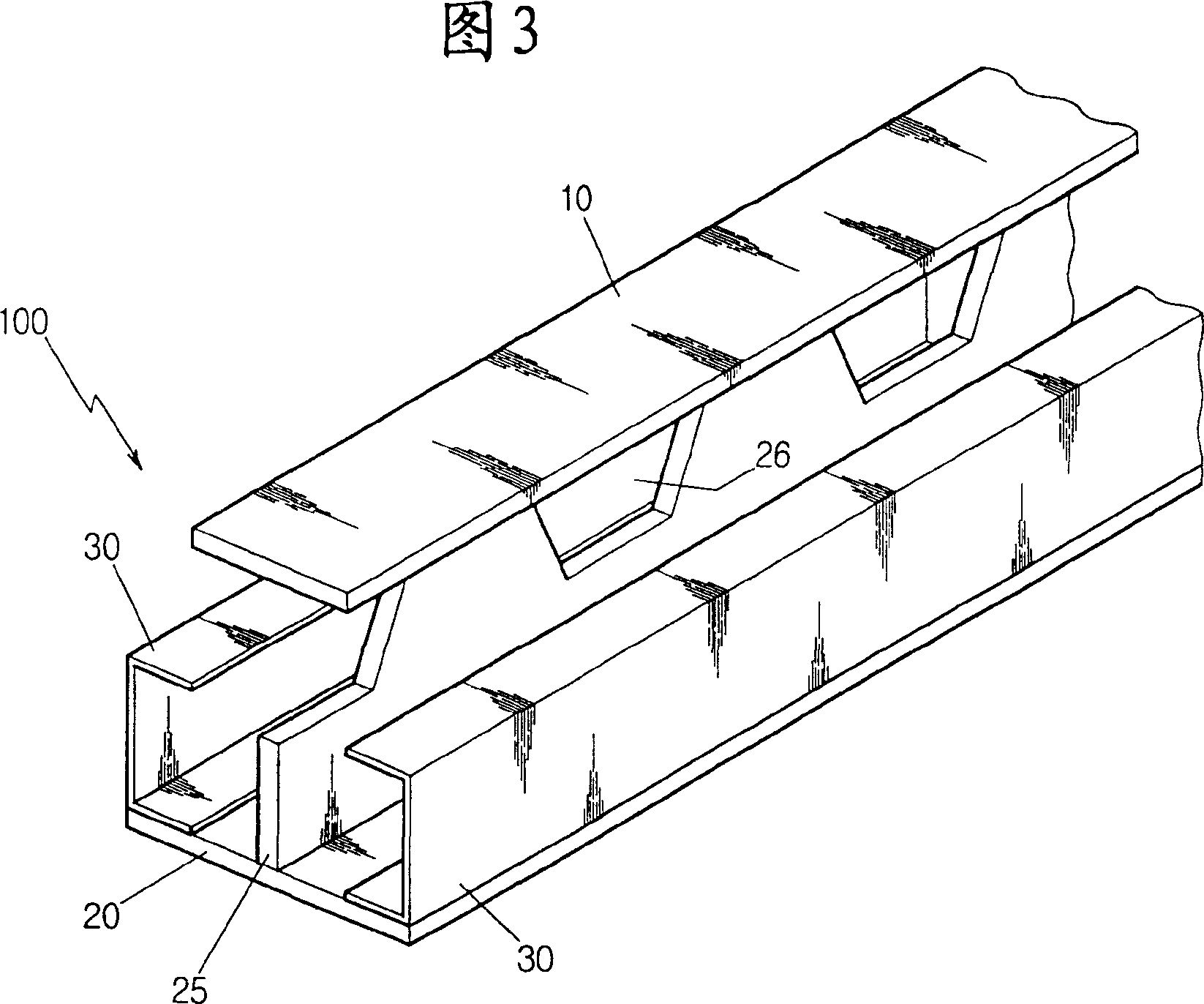

[0022] Fig. 3 is a perspective view of an asymmetric section steel beam used in the steel-concrete composite beam of the present invention. Figure 4 is a perspective view of an asymmetrical section steel beam provided with a metal cover plate prior to formation of the upper concrete slab.

[0023] As shown in Fig. 3, the asymmetric section steel girder 100 used in the steel-concrete composite beam of the present invention includes: an asymmetric I-beam with an upper flange 10, a web 25 and a lower flange 20; And a pair of C-section steel 30 connected to the lower flange 20 of the asymmetric I-beam. The asymmetric I-steel mentioned here refers to an I-steel with an asymmetric cross section, the width of the upper flange 10 is smaller than the width of the lower flange 20 . At least one opening 26 at a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com