Passive magnetic suspension brushless D.C. motor

A brushed DC motor and magnetic levitation technology, applied in the direction of magnetic circuit shape/style/structure, electrical components, electromechanical devices, etc., to achieve the effect of improving system efficiency, improving operational reliability, and simple control technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

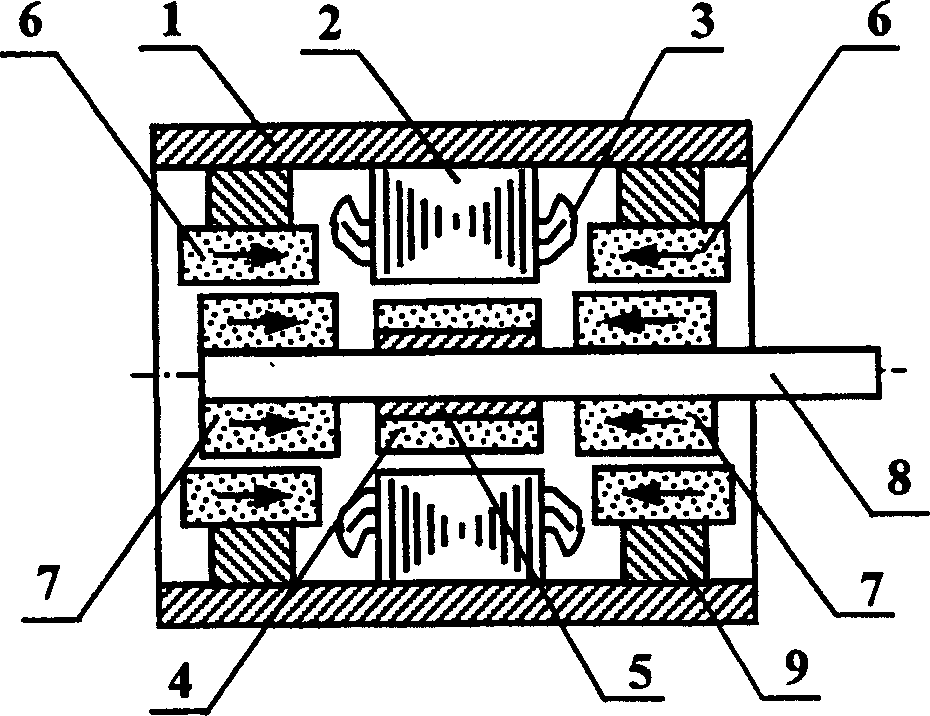

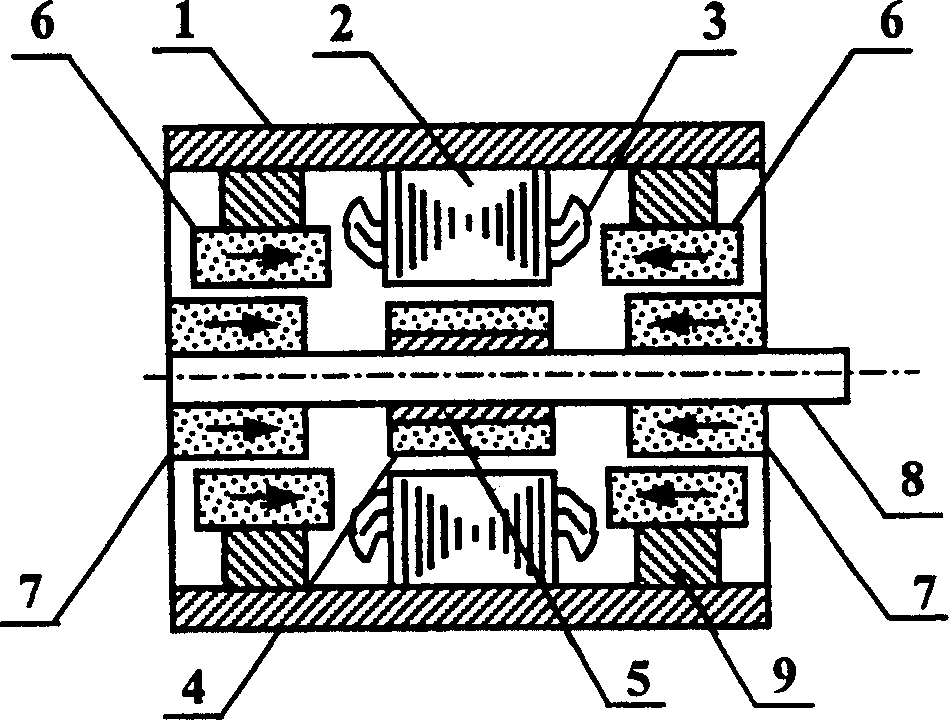

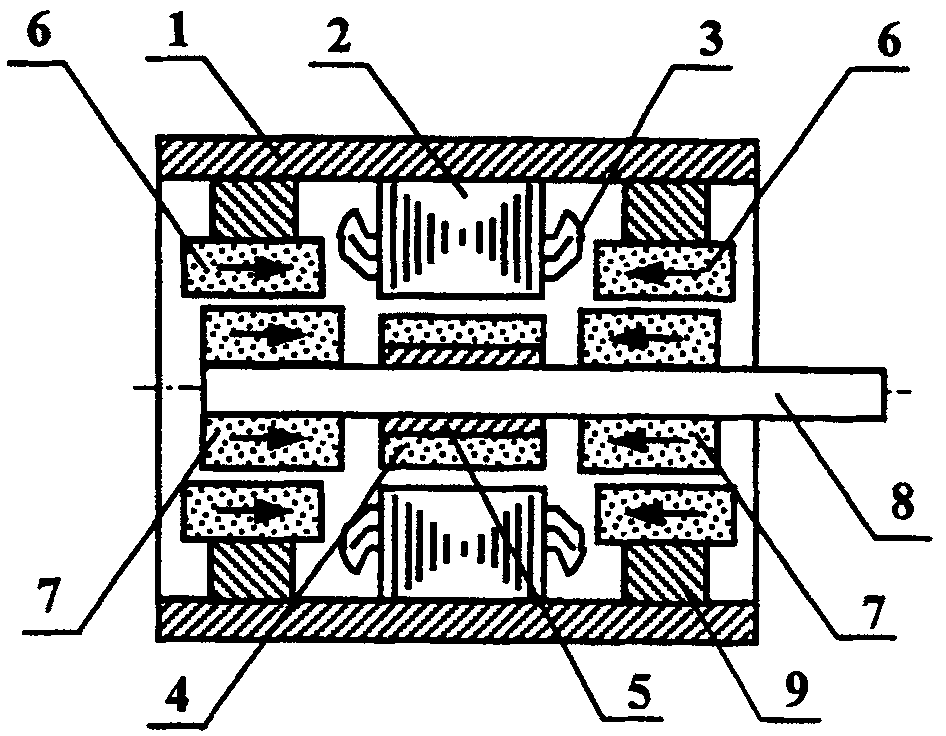

[0010] As shown in the accompanying drawings, the present invention is mainly composed of two parts, a motor and a passive magnetic bearing. The motor is composed of a stator core 2 fixed on a casing 1 , a stator winding 3 , and a permanent magnet rotor 4 fixed on a rotor yoke 5 and a non-magnetic rotating shaft 8 . The stator core is made of laminated electrical steel sheets, and has a certain number of slots for placing the stator windings, and the power wires of the windings are drawn out through the holes on the housing 1 . The permanent magnet rotor 4 consists of radially magnetized permanent magnets. The passive magnetic bearing consists of two sets of permanent magnet inner rings 7 and outer rings 6 with the same geometric size and magnetic performance. The axial magnetization direction of each set of permanent magnet rings is the same, while the axial magnetization direction of the two sets of permanent magnet rings on the contrary. The inner ring of each set of perm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com