A permanent magnetic levitation device for linear motion

A linear motion and magnetic levitation technology, applied in the field of magnetic levitation, can solve problems such as inability to guarantee levitation, and achieve the effects of compact structure, simplified structure and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

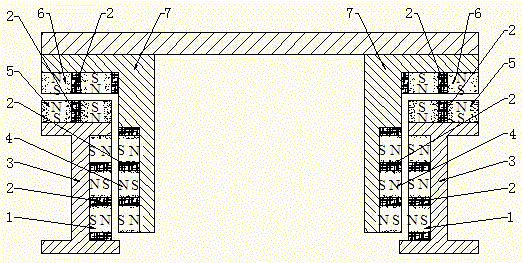

Embodiment 1

[0028] Such as figure 1 As shown, a permanent magnet magnetic levitation device for linear motion includes a track 3 and a bearing assembly 7. Two sets of suspended and fixed permanent magnet arrays 1 are respectively fixed in the grooves inside the "I"-shaped steel track 3, and the two sets of suspended The movable permanent magnet array 4 is fixed on the vertical end surfaces on both sides of the bearing assembly 7 and corresponds to a set of floating fixed permanent magnet arrays 1 respectively; On the upper plane, two groups of guided movable permanent magnet arrays 6 are fixed on the horizontal end surfaces on both sides of the carrier assembly 7 and are respectively parallel to a group of guided fixed permanent magnet arrays 5 directly below the guided movable permanent magnet arrays 6 . At this time, the oppositely arranged guide fixed permanent magnet array 5 and the guide movable permanent magnet array 6 are located on the upper side of the oppositely arranged suspend...

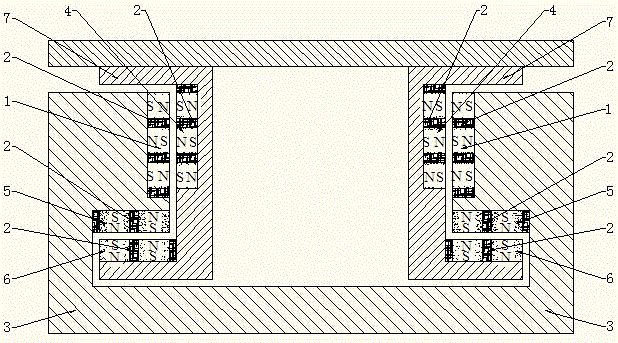

Embodiment 2

[0031] Such as figure 2 As shown, the difference from Embodiment 1 is that the present embodiment locates the opposite fixed permanent magnet array 5 and the movable permanent magnet array 6 at the position of the suspended fixed permanent magnet array 1 and the movable permanent magnet array 4 that are oppositely arranged. The lower side makes the guided movable permanent magnet array 6 of the carrying assembly 7 placed below the track guided fixed permanent magnet array 5, so that the vertical direction between the track guided fixed permanent magnet array 5 and the guided movable permanent magnet array 6 can be made The attractive force can counteract a part of the gravity of the bearing assembly 7 and enable the bearing assembly 7 to bear a greater load.

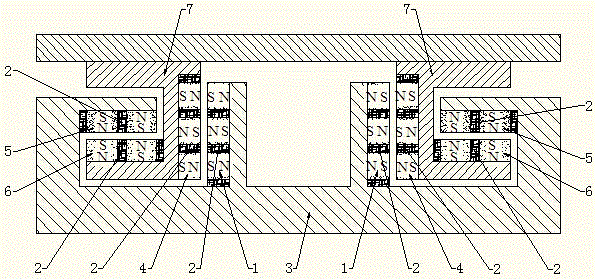

Embodiment 3

[0033] Such as image 3 As shown, the suspended movable permanent magnet array 4 and the guided movable permanent magnet array 6 on the carrier assembly 7 are arranged at the same horizontal position, and the suspended fixed permanent magnet array 1 and the guided fixed permanent magnet array 5 on the track 3 are also arranged at the same horizontal position. At the same horizontal position, compared with Embodiment 1 and Embodiment 2, the installation space of the device in the vertical direction is reduced, making the structure more compact.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com