Liquid-phase sandwich nanometer colloid particle laser protective materials

A nano-colloid and laser protection technology, which is applied in optics, optical components, optical components, etc., can solve the problems of affecting safety, secondary damage, and low light damage threshold, and achieve high safety performance, effective protection, and large reliability. The effect of selecting a range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

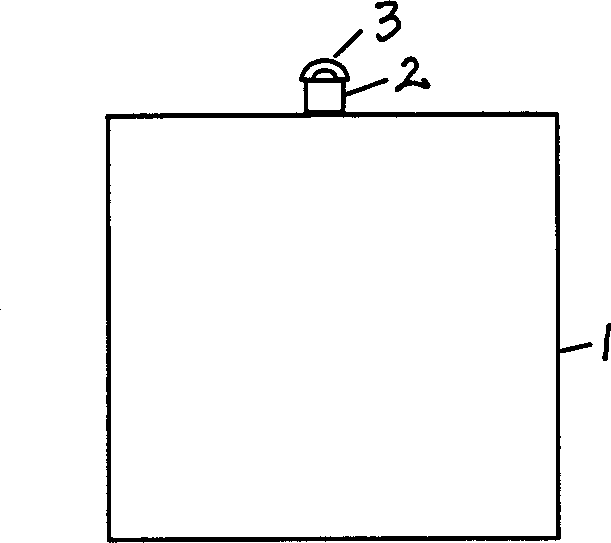

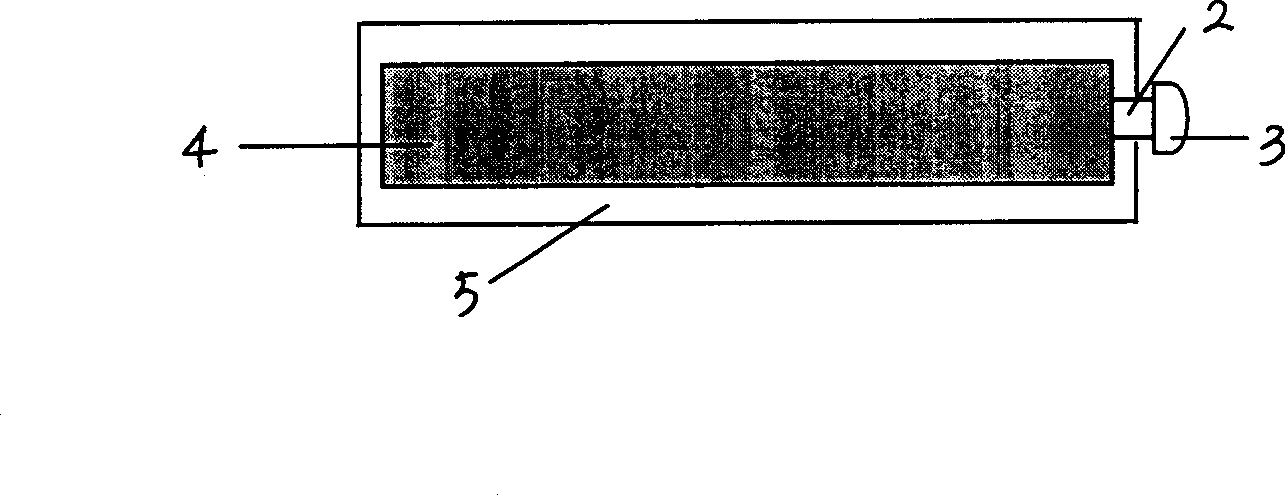

[0031] see figure 1 , figure 2 .

[0032] The present invention has two pieces of glass sheets 1 to form a sandwich structure, an injection port 2 is arranged on the interlayer, and the silver nano colloid particle solution 4 is injected, and a rubber cap capsule 3 is set on the injection port 2, which acts as a seal to prevent the solution from flowing out. Elasticity can adjust the change of solution volume caused by the change of temperature; the glass sheet 1 is quartz glass or ordinary optical glass, the shape is square, polygonal or circular, the thickness of the glass is 3-5mm, and the thickness of the interlayer is 5-10mm.

[0033] Silver nano colloid particle solution raw material formula is

[0034] Ethylene glycol 100ml

[0035] Polyvinylpyridine 0.2g

[0036] Silver nitrate 50mg

[0037] Dissolve polyvinylpyridine and silver nitrate in ethylene glycol, and then irradiate with γ-irradiation for 30 hours. The obtained silver colloidal particle solution is furth...

Embodiment 2

[0039] Silver sulfide nano colloid particle solution raw material formula is

[0040] Tetrahydrofuran 100ml

[0041] Polyvinyl alcohol 0.5g

[0042] Silver nitrate 200mg

[0043] Thioacetamide 50mg

[0044] Dissolve polyvinyl alcohol and silver nitrate in tetrahydrofuran, then add thioacetamide, after dissolving, heat the solution to 50-160 degrees Celsius and keep it warm for 5-50 hours, and the obtained colloidal particle solution is further diluted with solvent to make silver sulfide nano colloid particle solution. That is, the laser protection material of the present invention is obtained.

Embodiment 3

[0046] The raw material formula of lead sulfide nano colloid particle solution is

[0047] Pyridine 100ml

[0048] Vinylpyridinone 0.5g

[0049] Lead nitrate 300mg

[0050] Thioacetamide 100mg

[0051] Dissolve vinylpyridinone and lead nitrate in pyridine, then add thioacetamide, after dissolving, heat the solution to 50-160 degrees Celsius for 5-50 hours, and further dilute the obtained colloidal particle solution with solvent to make silver sulfide Add 80 mg of Danthrene to the nano colloid particle solution to obtain the laser protection material of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com