Sheath-core polyester fiber including antimicrobial agent

An antimicrobial agent, polyester fiber technology, applied in the direction of fiber chemical characteristics, single-component polyester artificial filament, conjugated synthetic polymer artificial filament, etc., can solve the problem of color-changing spinning productivity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

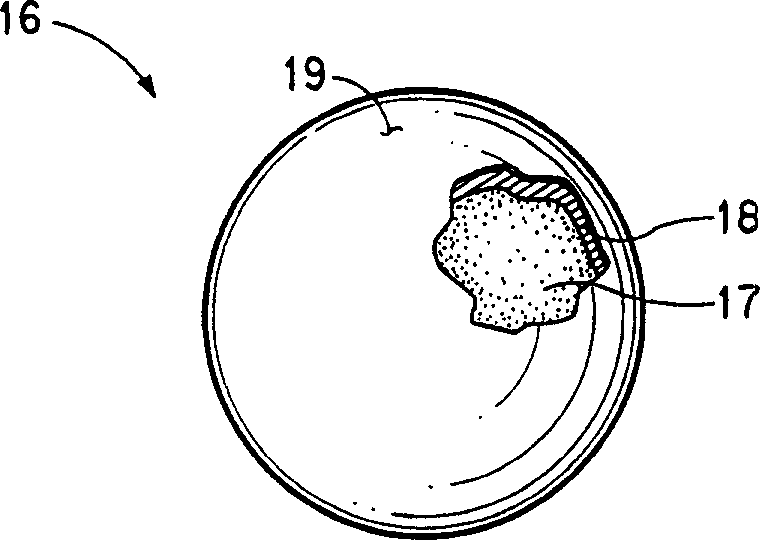

Image

Examples

example 1

[0067] Use 2G-T polymer flakes of LRV23.5 to prepare antimicrobial agent masterbatch, the method is as above for Figure 4 instruction of. The masterbatch is dried with dry air at about 166° C. before bicomponent spinning, for example in 80 in FIG. 5 . 2G-T polymer flakes were also used as skin and core polymers, respectively. 2G-T polymer sheets for the skin were dried using dry air at about 160°C, eg in hopper 90 of Figure 5, and for the core at a temperature of about 150°C, eg in hopper 100 of Figure 5 . The polymer for the skin is processed through a single screw extruder, such as extruder 85, 86 shown in Figure 5, which is modified so that the volumetric metered additive masterbatch provides 6 wt. % Antimicrobial Powder, the extruder was operated at a discharge temperature of 277°C at a rate of 252 lbs (144 kg) per hour. The polymer for the core is processed through a conventional single screw extruder, such as extruders 103, 104 shown in FIG. condition.

[0068] The...

example 2

[0075] The core sheath fiber of Example 2 was prepared similarly to Sample A of Example 1, except that the antimicrobial masterbatch was metered in so that the sheath of the silk contained 5 wt% of the antimicrobial powder. Additionally, the skin and core polymer streams were combined in a 3:7 ratio to yield a 30% skin (containing 5% antimicrobial). This example is identified as Example 2 in Table 3 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com