Ferroelectric liquid crystal display, and its driving method

A technology of ferroelectric liquid crystals and display elements, applied in static indicators, instruments, nonlinear optics, etc., can solve problems such as insufficient prevention of image persistence and image persistence, and achieve reduced display flicker, good display, Effect of preventing threshold voltage change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

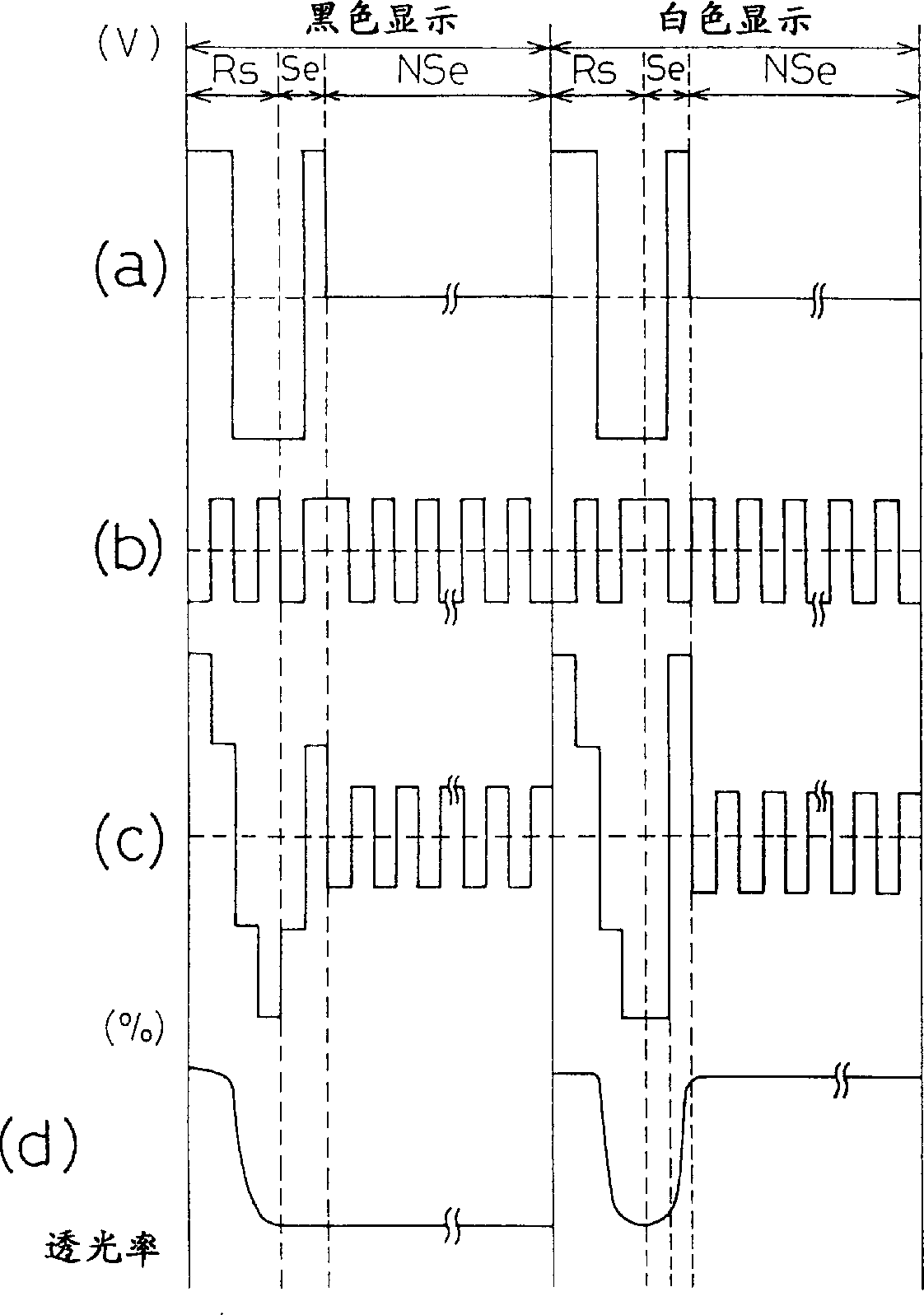

[0059] Figure 11 is a schematic diagram showing a method of synthesizing driving voltages according to the first embodiment of the present invention. This way corresponds to image 3 (c) Synthetic voltage driving method shown.

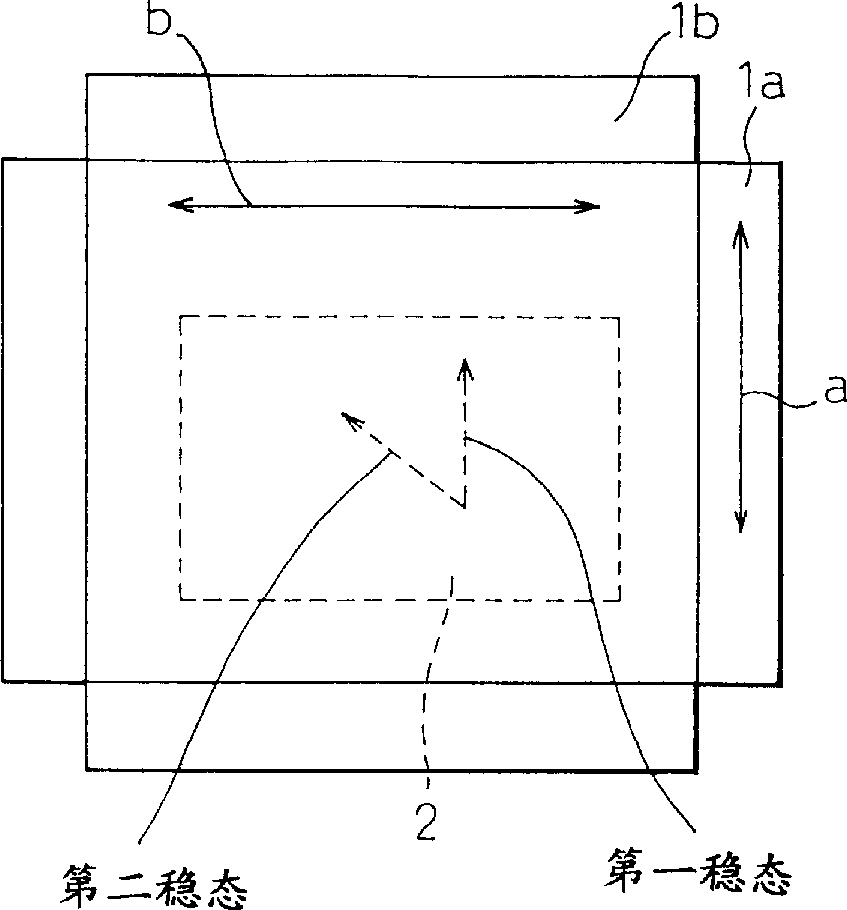

[0060] N=1 indicates the composite voltage mode applied to the pixels on the scan electrodes of the first row, N=2 indicates the composite voltage mode applied to the pixels on the scan electrodes of the second row, and N=240 indicates the composite voltage mode applied to the 240th row Synthetic voltage mode of the pixel on the scan electrode. In the present invention, all pixels are simultaneously placed in the black display state in the reset period (Rs) immediately before the selection period (Se) in which the necessary display data is written, and then each scan electrode is sequentially Writing is completed by applying a selection pulse. As shown in Figure 6, the reset period (Rs) is divided into two periods, the switching period (Sw) and th...

Embodiment 2

[0065] Figure 13 is a schematic diagram showing a method of synthesizing driving voltages according to the second embodiment of the present invention. In this embodiment, a reset period (Rs) is provided every time display data is written to a pixel. For each scanning line, the reset period is set such that the lengths of the switching period (Sw) and the non-switching period (NSw) are the same for all pixels. The length of the reset period (Rs) of each pixel is set to 8.2 ms, and the lengths of the switching period (Sw) and the non-switching period (NSw) are set to about 8 ms. The bipolar pulse applied during the switching period (Sw) and the selection pulse applied during the selection period (Se) are the same as in the first embodiment. As a result, the change amount of the threshold voltage is the same for all scanning lines, and better display quality can be achieved.

[0066] In this embodiment, a black display is generated during the reset period, of course, the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com